Print this article Font size 16

The design of starters on the VAZ 2109 has fairly good reliability indicators. But with use and over time, they still fail.

Appearance of the device

Design and operating principle

To understand the features of the repair, you must first study the design of the starter and understand how it works for the benefit of your car.

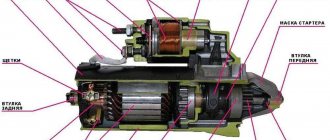

Let's start with the design. It includes four main nodes.

| Knot | Peculiarities |

| Electric motor | It transmits direct current through four brushes |

| Freewheel with gear | A clutch or bendix drives the flywheel of your car's engine. |

| Traction relay | Serves to extend the bendix with gear when turning on the electrical appliance |

| Bushings | Ensure easy rotation of the clutch, rotor, and gear. One bushing is located inside the starter, and the second is in the clutch housing. |

Device diagram

Having familiarized yourself with the starter diagram, you can discuss the principle of its operation.

The operating principle is to convert an electrical signal into the rotational movement of a drive gear. Current is transmitted through the brushes to the poles of the electric motor. At the same time, the clutch extends and the gear is connected to the flywheel ring. To start the engine you need a quick but easy rotation of the starter. When the engine starts, the clutch returns to its original position.

Disassembling the starter of VAZ 2108, 2109, 21099 cars: 1 comment

I looked through a bunch of sites, but it was on this starter that your information turned out to be the most useful. Many thanks to the author of this guide

The design of starters on the VAZ 2109 has fairly good reliability indicators. But with use and over time, they still fail.

Appearance of the device

Typical faults

It is better to start diagnosing the starter even before you remove it.

After dismantling, some signs of failure, by which the source of the problems can be determined, can no longer be determined.

Signs of a faulty element include:

- An unusual noise occurs when the engine starts;

- Complete absence or slow rotation of the starter;

- Rotation occurs, but there is no gear engagement with the Bendix ring;

- The unit rotates with the bendix, but then the clutch breaks;

- Turning the key in the ignition, there is silence.

Checking the dismantled unit

Before blaming the starter for everything, take the time to look under the hood and check the condition of the terminal contacts and connectors. Also pay attention to whether everything is ok with the battery. Only after this can you start working on the starter.

The most common starter failures

It is recommended to carry out troubleshooting while it is running on the car, because after dismantling the starter, it will be quite difficult to identify some breakdowns. The main symptoms are expressed in the following situations:

- Uncharacteristic noise when starting the engine.

- slow rotation or no rotation at all.

- The device rotates, but the gear does not engage with the flywheel.

- The starter rotates with the flywheel, but subsequently there is a gap in the engagement.

- When you turn the key, there is no sign of the device being “working.”

In each of the above cases, it is necessary to look at the engine compartment. It is likely that the problem may be hidden in poor contact connections and electrical connectors. Additionally, check the condition of the battery; it may be discharged.

Diagnostics

To carry out diagnostics, arm yourself with a conventional tester with voltmeter mode.

- Connect the battery terminals to the poles of your measuring device. You will need an assistant to drive.

- After connecting the terminals to the voltmeter, look at the readings of the device. If the battery is working properly, the data will be 11-13 V.

- Turn the ignition key and at this moment measure the voltage. If the losses are only 1-2 Volts, then the starter works normally and does not show resistance.

- If the voltmeter parameters decrease by 2 times or more, the reason is in the starter. Or rather its bushings or brushes.

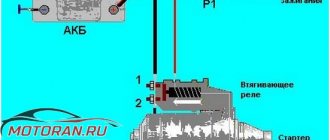

- Remove the starter and check the relay. Connect the battery terminals to its terminals on the body and transfer it to 12 V. If the overrunning clutch moves in the front cover, then the relay works perfectly. If not, replace it.

A few words about the nine starter

Before we learn how to use the repair kit for the starter we are interested in, let's figure out what this mechanism is. It is a simple electric motor with four poles and brushes, which is attached to the flywheel ring gear. The following starter models were installed on “nines” of different years of production: 29.3708; 5712.3708; 423.3708.

Any of them operates on a mixed excitation principle and has a traction relay with two windings. The differences between these starters lie in the design of the commutator device and the drive. Thus, the model 423 mechanism has a cylindrical type commutator, the 29 model has an end-mounted one, and the 5712 starter has a planetary gearbox installed in the drive. Their repair kit is absolutely identical, as well as their malfunctions.

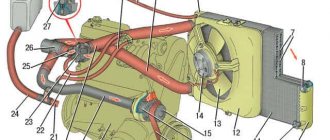

Removal

Well, the check showed that the starter needs to be repaired. Therefore, the first thing we do is dismantle it.

- Secure the car stationary by turning on the handbrake and placing stoppers under the wheels.

- Move the negative terminal from the battery to the side. This will deprive your car of power.

- Disconnect the wire connector from the starter solenoid relay terminal.

- Unscrew the fastening nut from the relay contact bolt and remove the wire.

- If there is a crankcase guard, remove it. Here all the bolts are simply unscrewed.

- The 2 starter fixing nuts are unscrewed from the bottom of the engine compartment. But the third one is more conveniently removed from inside the engine compartment.

- Having removed the fasteners and disconnected the wiring, you can safely remove your starter from the clutch housing.

Before starting work, be sure to clean the device from accumulated dirt so that it does not get inside the structure and reduce all repair efforts to nothing.

Repair

Next, you have to check the condition one by one and take appropriate measures to eliminate problems with the following components of the starter:

- Brushes;

- Anchor;

- Overrunning clutch;

- Traction relay;

- Bushings.

Now let's talk about everything one by one.

Brushes

First, assess the current condition of the brushes. In most cases, they are the source of problems with the starter.

- Remove the pair of screws that hold the protective cover in place. The cover is now easy to remove.

- Use a screwdriver to remove the retaining ring from the shaft, and don’t forget about the adjusting washers.

- Unscrew 2 more tie rod nuts. Remove the manifold side cover.

- Use a screwdriver to press out the springs and remove the brushes from the holder.

- Measure the brushes with a caliper or ruler. If the height is less than 12 millimeters, the brushes must be replaced.

- It is also better to replace elements if there are chips, cracks and other defects on the surface.

Brushes

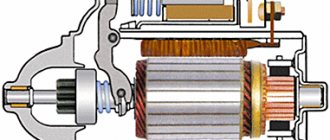

Anchor

If all is well with the brushes, the next suspect is the anchor.

- Remove the housing with the starter.

- At the anchor, look at the condition of the commutator, check whether the winding is intact.

- If there is carbon deposits on the collector or signs of breakdown, clean these areas with fine sandpaper.

- Check the armature and stator windings using a multimeter in ohmmeter mode.

Overrunning clutch

Parallel checking of the overrunning clutch with the armature will allow you to replace the latter at the same time.

To gain access to the clutch you will have to remove the armature from the front cover. At the same time, change it if necessary.

- Remove the retaining ring located near the overrunning clutch.

- Remove the restrictor ring.

- Remove the plastic lever stop, which will allow you to reach the anchor.

- Remove the intermediate support from the shaft.

- Check the condition of the gear teeth. If there are defects, the unit is replaced with a new one.

Bendix or overrunning clutch

Traction relay

Replacing the traction relay is necessary if, when voltage is applied to its terminals, the overrunning clutch does not extend. Sometimes the VAZ 2109 is equipped with collapsible relays. But it’s still better not to repair it, but to replace it with a new relay.

- To remove the relay, unscrew the two screws located on the front;

- Lift the relay, disconnect the armature from the lever;

- Remove the relay from the housing, grabbing the spring and armature. All elements are changed if necessary.

Relay

Do-it-yourself VAZ 2109 starter repair - an opportunity to save a lot of money

VAZ 2109 starter

As you know, the starter is one of the most important parts of a car. The malfunction of this element is easily detected, even by inexperienced drivers. Such repairs can be done on your own, you just have to have the instructions at hand, which will be given below. In this article, we will look at the starter of the popular car of the golden youth of the 90s, VAZ 2109.

This car became the ancestor of a large number of cars.

VAZ 2109 starter before repair

But as a result of use, this model began to crumble just like the previous Lada. Parts began to fail again, just like on the previous Zhiguli. The starter, which was the main part of the starting system, suffered especially, and was often subjected to heavy loads, especially in the winter.

How to repair a starter yourself

Repairing the VAZ 2109 starter is not particularly difficult for an experienced driver who has become familiar with this part in old models of classic Zhiguli cars. This part is quite simple in its design, like most cars of this family. The part consists of:

- a direct current electric motor, which has 4 poles equipped with an electromagnetic switch;

- there are also freewheels;

- traction relay.

Starter malfunctions

Malfunctions of this part are easy to distinguish. The overall design of the “nine” starter has not undergone absolutely any changes, although the developers have modernized some elements. So:

- The main difference from previous starter models is the shaft sleeve, which is no longer installed in the starter, but in the clutch system. And this element is often forgotten when carrying out repair work by people who have not received special technical education and have not studied the “nine” scheme. To replace the starter bushing on a VAZ 2109, you need to have some skills. If you have not done this work before, then you may find yourself face to face with various difficulties.

- Another malfunction that I would like to highlight is the VAZ 2109 starter solenoid relay. This part also becomes the culprit of V9 starter malfunction quite often. Its breakdown can be considered empty repeated operation, not holding the gear in the required mesh.

Otherwise, defects associated with the VAZ 2109 modification starter are as follows:

- the starter shaft does not rotate or does so very slowly;

- the gear slips, this happens when there is poor engagement with the flywheel ring, although the shaft rotates;

- During operation, the starter makes knocking noises or an uncharacteristic sound.

If you notice one of the above malfunctions, you must immediately proceed to repair. If you do not do this work right away, then you risk permanently damaging the part and being unable to repair it.

Dismantling

Before troubleshooting, you should look at the battery's performance. Symptoms of a weak battery are often similar to starter motor problems. You should also check the following type of communication: battery / ignition switch / starter / traction relay. Removing the starter is not so difficult. To do this you need:

- remove the terminals from the battery;

- disassemble the engine crankcase protection;

- disconnect the electrical wiring terminals;

- Unscrew the nuts securing the starter to the crankcase (there are three of them).

Attention: During the dismantling process, it is necessary to pay special attention to such parts of the starter as the armature, the condition of the winding, gear defects, cleanliness of contacts and much more.

Direct repair

You should not think that before removing the starter, you need to lift the VAZ 2109 car into the inspection hole. We begin to repair the starter after it has been completely removed. So let's begin:

- we check the relay by applying a voltage of 12 V to the output, do not forget that the minus should be short-circuited to the body;

- At the same time as this procedure, we attach an ohmmeter to the contact bolts (if the relay is working normally, the coupling should move into the hole when current is received, and the bolts should close - if this does not happen, then the relay should be replaced).

checking the starter relay VAZ 2109

- check the brushes;

- the starter cover is removed, after which the screw securing the fastening of all wires is unscrewed;

- the spring is removed;

- the brush is removed (as a rule, its minimum height should be 12 mm - otherwise, this means its erasing and mandatory replacement).

checking the starter brushes

We continue to work with the VAZ 2109. The starter, the repair of which is carried out by hand, must be carefully inspected. At this stage, you can even arm yourself with a magnifying glass in order to see everything better. Let's move on to the next action:

- we check the winding of the starter itself (as mentioned above, this device is not particularly different from other VAZ 2109 models, and do-it-yourself repair of the starter must be carried out skillfully and you need to know all the basics of the circuit);

- take an ohmmeter and check for a short circuit between the turns and on the body;

- inspect the collector and other windings (to do this, you need to carefully remove the ring so that it does not fly off, and pull it out);

- remove the washer from the axle;

- unscrew several bolts;

- we disconnect the tubes that serve to insulate the coupling bolts and pull them out;

- carefully inspect the collector and winding (there should be no soot or surf on them);

- Use sandpaper to wipe away minor changes on the surface.

Repairing the starter on a VAZ 2109 with your own hands also involves a thorough check of the armature winding.

- take a 220 W test lamp;

- we check the insulation for rupture, determine the runout of the shaft (which should be 0.08 mm, the insulation resistance should be at least 10 kOhm;

- we connect the armature collector with one wire with a current of 220 V;

- We connect the second wire through a 220 W 100 W lamp to the power housing (if the lamp lights up, then there is a breakdown in the armature and it needs to be replaced.

On a VAZ 21099 car, repairing a starter, where the armature is in order, also involves inspecting and checking the collector. Some important tips:

- if burning of the plates in two places is detected on the collector, then the coil is broken;

- if the plates turn blue, then a turn short circuit has occurred (this happens rarely, but it does occur):

- an interturn short circuit is detected on visible sections of the armature wire or bus bar (usually the turns are wrinkled or bent);

- Short circuits can be eliminated and tire bruises can be corrected by checking for the presence of foreign bodies;

- if the short circuit is not found, all that remains is to rewind the anchor.

On a VAZ 21093 car, repairing a starter, as well as on a VAZ 21099 and 2109, after checking the windings, involves inspecting the couplings and gears. To do this, we carry out the following type of operations:

- remove the washer from the armature axis;

- pull out the anchor assembly with the drive;

- remove the clutch drive lever;

- We begin to rotate the gear (there should be no chips or nicks; if there are any, it is advisable to replace the device).

A video can certainly help in this matter, but first of all you should understand what you are doing and how it works.

Attention: When assembling the starter in reverse order, it is advisable to check its casing. All plastic parts must be covered with lithol (pictured below), even if they are in good condition.

The instructions also recommend lubricating all parts that rub with machine oil for prevention. Having learned how to repair a starter with our own hands, we get a unique opportunity not only to repair our favorite car efficiently, but also to really save money. After all, the price of a new starter is not cheap in stores, and it is not always possible to find a good one.