If, when turning the key in the ignition switch, the starter simply clicks, but does not turn and, as a result, the engine cannot start, the reason here is quite simple and now we will deal with it in detail.

It's clear that when a car doesn't start right away, it annoys any motorist. The reasons are as follows: the contacts on the battery may simply become disconnected, and there may also be a malfunction in the starter. But an experienced driver, based on certain signs and clicks, will always be able to understand in which particular unit the malfunction occurred.

The starter and retractor relay clicks, what is the reason?

If the starter clicks on a VAZ 2114 and does not turn, then everything immediately becomes clear . These clicks come from the solenoid relay, but this does not mean that you need to change the starter solenoid relay. Current flows to it, which is why it clicks.

If these devices click, then this is not bad, because if there are clicks, then these devices are operational or partially operational.

In most cases, solenoid relays use an electromagnetic method to connect contacts.

When voltage is applied, the contact terminals receive charges with opposite poles, so they begin to attract and when they touch each other, they create a clicking sound.

In order for the engine to start, you need to make sure that these components are in good working order:

- the battery is charged with well-connected terminals;

- The ignition switch and its contacts must be in order;

- the starter relay, the solenoid relay and the starter itself.

Video tip: The starter clicks but does not turn:

Causes of malfunction

Before we begin to study the causes of the malfunction, we remind you that hereinafter we are talking about the crackling noise of the starter, which is most similar to the loud rattling of the contacts of an electromagnetic relay. If you hear an unpleasant metallic grinding noise from under the hood, then it appears due to poor engagement of the overrunning clutch (starter Bendix) with the flywheel teeth - that’s a completely different story.

Most often, the starter crackles when you turn the ignition key for three reasons:

Low battery

To understand the cause of the crackling noise due to a discharged battery, let's remember the starter device. When you turn the ignition key, the voltage from the on-board network is supplied to the coil of its solenoid relay. The electromagnetic forces that appear in this case cause the armature of the device to move. It closes the power contacts that connect the starter motor to the battery, and in addition, causes the Bendix gear to engage with the flywheel.

When the battery is discharged, its energy may be enough to attract the metal core - cranking the crankshaft is out of the question. As soon as the starter contacts close and power is supplied to its electric motor, the voltage drops to such an extent that the electromagnet is unable to hold the metal core. Under the action of the return spring, it tends to take its original position and opens the power contacts. The restored voltage contributes to the repeated retraction of the anchor, and the situation is recreated many times.

To make sure that the culprit of the problem is a deep discharge of the battery, just turn on several consumers (lighting, electric heater motor, etc.) and press the sound signal. The latter will either not turn on at all, or will be heard with wheezing, reduced amplitude or attenuation.

Poor engine ground contact

The picture of what is happening is practically indistinguishable from the case discussed above, with the only difference that the test for battery discharge ends with a negative result - all consumers, including the sound signal, are working at full strength.

At the same time, it is very simple to determine that the cause of the malfunction is poor contact between the battery and the engine - just pay attention to the oil pressure warning lamp, which is located on the instrument panel. If the voltage in the car’s on-board network is below normal, then turning the ignition switch to the “Start” position will lead to a gradual attenuation of the brightness of the warning lamp (like all others).

In the case where the cause of the crackling sound of the starter solenoid relay is a bad ground, an attempt to start the engine will lead to its complete extinction in time with the clicks of the solenoid relay. At the same time, other indicators practically do not change the intensity of the glow.

Everything is explained very simply - the “mass” of the oil pressure sensor, as well as the starter, is the housing. Therefore, as soon as the electrical contact between the engine and the battery is lost, both of these devices stop working synchronously.

Open or shorted starter relay winding

Another reason why the solenoid relay cracks is an interturn short circuit or a break in its holding winding. In other words, the efforts of the electromagnet become insufficient to keep the power contacts of the starter relay in the closed state and engage the overrunning clutch gear with the flywheel ring gear. Under the action of the return spring, the bendix tends to take its original position, and the contact pad located on the armature opens the electrical connection. After this, the retractor winding turns on again and the situation repeats itself many times, which causes the crackling noise.

to determine that in this case the starter solenoid relay has failed by the behavior of the warning lamps located on the instrument panel. At the moment when the loud clicks of the starter are heard, their brightness does not change - the switching of the starter motor occurs for such a short time that the battery voltage practically does not drop.

Something else useful for you:

The relay clicks, but the car does not start, what should I do?

As you understand, if there are clicks, then there is still hope that the car will be able to start. If the starter does not spin, you should definitely pay attention to the contacts of the traction relay. Therefore, the first thing you need to check is the following:

- battery, clean the terminals, perhaps there is simply no contact;

- check if the wires leading from the battery to the starter are in order;

- twitch the key in the ignition switch, perhaps there is a contact somewhere;

- the starter is broken, in this case you will have to remove it and reassemble it, but before that you need to make sure that there is no contact on the brushes;

- If the solenoid relay is broken, then you will just have to replace this unit.

Usually, the starter breaks down quite rarely, and so does the solenoid relay, so most likely it’s all about a discharged battery or missing contacts. If the battery has a weak charge, then it is clear that there will not be enough energy to turn the starter, but it may be enough to operate the charge relay, which is why these clicks are heard.

There are times when the starter takes over the current.

Starter device

If you don’t get into the weeds, this is an ordinary POWERFUL electric motor, which is used for only one task - spinning the crankshaft to start the engine. But as I wrote above, it should not be constantly engaged, and therefore a “special unit” brings a certain gear into engagement with the flywheel and removes it after starting.

This gear is called “BENDIX” , it is the one that meshes with the flywheel. However, the Bendix device is much more complicated; it is essentially an overrunning clutch (it can rotate in one direction, but not in the other).

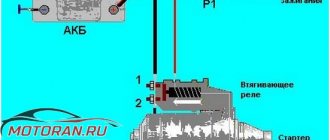

The Bendix pushes out a special unit, which is (usually) attached to the top of the starter and is called a “retractor relay” . As you understand, it has one task - to engage it with the flywheel and, after starting, to remove it and put it back. The principle of this unit is based on the operation of an electromagnet, one of its contacts is always connected to the negative (through the starter housing, then through the vehicle ground), and the other to the positive of the battery (through the ignition switch). In order not to overload you with complex technical information, you need to understand that this magnet has a winding, let’s call it “retracting”, as well as a “core”, which, under the influence of these windings, moves in and is held (it is rigidly connected to the BENDIX). When you turn the key in the ignition, the “retractor winding” works; it acts on the core, the “BENDIX” extends, which engages with the flywheel and then the starter spins the engine. After starting the engine, the winding opens, a special spring moves the core to its original position, and the BENDIX disengages.

At the end there will be a useful video, watch it, all questions will disappear.

In simple words, the “retractor relay” engages and then removes the BENDIX gear from engagement with the flywheel.

How to check the starter

If everything is fine with the battery and the contacts too, then the problem is in the starter. and clicks for this reason . What should I do if the starter clicks but does not turn? To diagnose it and find out where exactly the clicks are coming from, you will have to remove the starter.

You may also be interested in: The best Italian cars: Ferrari, Lamborghini, Maserati and others

Then you need to put this starter on the table, take a charged battery and connect ground to the starter body, and connect the positive terminal to the pin that comes after the relay. If the starter turns, then everything is in order and there are no problems with the retractor relay either. And if the starter clicks, but does not turn as before, this means that there is a malfunction in it and you will have to disassemble it and look for the breakdown inside . The same must be done if the starter idles and does not engage.

Clicking sounds are heard, but the starter does not turn due to the windings or brush assembly

If the battery, ignition switch, contacts, wiring and starter relay are checked, but it still does not rotate when you turn the ignition key, then the problem is directly in the starter. In such a situation, you will have to completely remove it from the car, disassemble it and evaluate the possibility of repairs. You can also simply replace the starter with a new one.

If you decide to repair the starter yourself, know that the problem with it refusing to rotate under load may be due to:

- Faulty winding, which has a characteristic burnt color and smell;

- A faulty brush assembly, the wear of which is easily determined visually.

Starters are rarely repaired, and such a step should only be taken as a last resort. If it is possible to replace the starter, then it is better to do this than to bother with repairing the winding or brush assembly.

( 408 votes, average: 4.57 out of 5)

Alternator belt whistles: main causes and troubleshooting methods

The starter turns for a long time when starting the engine

Related Posts

The relay clicks, but the car does not start, how to start the car?

It seems like such a small unit, but it could be the reason why the car won’t start . But if you have a VAZ 2121 or any other VAZ with a manual transmission, then there is an excellent way out of the situation - just take and start the car from the pushrod. To do this, you need to turn the key, as you usually turn it when you want to start the car.

Then find several people and the whole crowd needs to push the car and continue to push it until the speed becomes more or less normal - about 5 km/h or more. At this moment you need to squeeze the clutch, engage 2nd gear and release the clutch, the car will jerk and should start, you need to give the gas at the moment when the car tries to start. If the car stalls, you need to repeat these steps. If it doesn’t stall, then you can drive on without stopping.

And you have to drive carefully so that the car doesn’t stall at a traffic light, and of course, you don’t have to turn off the engine yourself. If there is no one around to ask to push the car, then you need to look for a hill nearby and push the car yourself up to this hill and drive off it. When the car starts to roll down the hill, you can also turn the ignition key and engage second gear and release the clutch.

In general, the car will start this way without a starter and without a battery..

Video advice is a useful way to get out of a situation where the starter clicks but does not turn:

Device and connection diagram of the starter

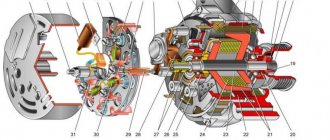

If the starter clicks, but does not turn or does not work when you turn the key on a VAZ 2114, first of all you need to diagnose the unit. But first, we recommend that you familiarize yourself with its device. This mechanism itself is a DC electric motor, and its design is quite complex. On the fourteenth VAZ models, units of model 5712.3708 are installed.

The main design elements are listed below:

- One of the main components is the moving part. It consists of an armature that rotates on a shaft.

- Solenoid relay. The starter turns thanks to a relay that transmits the corresponding impulse to the armature.

- Overrunning clutch or bendix. The main function of the device is to engage the flywheel of the motor.

- Frame. It contains all the working parts and components of the electric starter. A relay is mounted on the housing, and the structure itself is closed with two covers.

The main purpose is to spin up the engine flywheel, which happens when the starter turns. The mechanism is activated when the ignition is turned on. When you turn the key, the battery transmits an impulse to the solenoid relay. After the contact is closed and a click is heard, the impulse is transmitted to the armature. In order for the VAZ starter to always be in working condition, it needs to be serviced from time to time to identify faults.

Electrical diagram of the node connection

The starter clicks but doesn't turn over

Inspection of starter brushes on VAZ-2110

Very often, when the starter malfunctions, it is not the mechanism itself that is to blame, but its retractor relay. It is important to understand that when you turn on the ignition, it is not the starter that clicks, but the mentioned relay. Malfunctions consist of one of the following reasons:

- Failure of the power wire that connects the starter windings and the traction relay. To solve the problem it is necessary to replace it.

- Significant wear on starter bushings and/or brushes. In this case, they need to be replaced.

- Short circuit on the armature winding. You can check this using a multimeter. As a rule, the winding is not repaired, but another starter is purchased and installed.

- Short circuit or break in one of the starter windings. The situation is similar to the previous one. The device needs to be replaced.

- The fork in the bendix is broken or deformed. This is a mechanical failure that is difficult to fix. The optimal solution in this situation would be to replace the bendix or the fork separately (if possible).

Starter design

Regardless of the specific design, the electric starter includes a solenoid relay. The starter performs two functions simultaneously:

- The starter pushes the bendix and drive gear forward, allowing it to engage with the flywheel ring gear.

- The starter relieves the ignition switch contacts: the current consumed by the starter is large, and the solenoid relay allows you to control the starter using a relatively small current.

Solenoid relay design

The pull-in housing houses two windings of different power, drawing in (hence the name) the core. A fork is installed on the core, which moves the bendix through a lever, and at the end of the stroke the core closes power contacts (“nickels”) that supply power to the starter directly from the battery. Two windings are used to reduce current consumption: more force is required to retract the core than to hold it in place. As soon as the core of the pull-in relay closes the “nickels”, the pull-in winding is bypassed, and only the holding winding works.

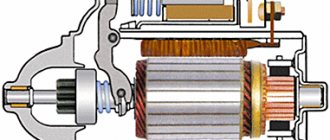

How does a starter work (its functions)

Typical starter design

The function of the unit is to take electrical energy from the battery, increasing the power of the electric motor through four commutator brushes. The current is supplied by closing the ignition by turning the key. The starter armature greatly increases the power of the voltage passing through it. An electromagnetic switch produces current and instantly engages the gears with the flywheel ring.

After starting the internal combustion engine, the bendix or overrunning clutch is disconnected from the flywheel, which extends its service life. The device rotates the crankshaft until the fuel mixture ignites.

Types of starters

New gear starter

There are starters with and without gearboxes, each of which has advantages and disadvantages.