23.06.2014

Engine assembly

Let's look at the reasons why the engine won't start. What are the solutions and what should a person who finds himself in this situation do? We will talk about Samaras with an injection engine, since there are few carburetor ones left today.

If we are talking about the cold season - you did not start in winter, then there are several nuances regarding the engine starting algorithm. Perhaps your candles have flooded or something else. To study this issue more specifically, read the article: How to start a car in cold weather? Where the algorithm is described and, again, possible causes of the malfunction.

Now we will talk more deeply about the technical part, since “winter factors” are no longer needed.

We will describe the problems in the order of the actions taken: that is, starting from the inserted key and ending with the operation of the engine.

The starter works, the engine turns, but the car does not start

So, the starter, like the engine, the pistons move, but the engine still won’t start. There is already a problem here, most likely in the fuel-air mixture, perhaps the marks have come off, etc.

Before you sin on this, the first thing you need to pay attention to is the crankshaft sensors:

DPKV - if it malfunctions, it is very difficult to start the engine, and once it is running, it runs unevenly, intermittently, and the power drops noticeably.

Next you should pay attention to the labels:

- Mark on the timing camshaft gear (photo).

- Markings on the flywheel under the thermostat (photo).

If the marks do not match, most likely the belt has simply slipped by one tooth. The camshaft gear itself may be worn. It needs to be adjusted and installed correctly!

Next we will talk about the air-fuel mixture.

I warn you in advance that the easiest way is to do computer diagnostics of the engine or look at the errors on the on-board computer.

The air-fuel mixture is the combination of air, gasoline, and the spark needed to ignite it.

Air supply

As a rule, a malfunction in the air supply should not affect the engine starting problem. At the very least, the engine should still run. Nevertheless, let's not bypass the air system.

The following sensors are responsible for air metering and supply:

- Mass air flow sensor is the most expensive sensor. If it fails, then the car simply begins to consume liters of gasoline, then this sensor can simply die “to zero”, but it indirectly affects the starting of the car. This means, no matter how it fails, the car should start.

- The IAC should not affect the engine starting problem. If it malfunctions, problems arise from idle.

Spark

Here may be the real reasons for our problem:

- First of all, we look at the candles. We turn them inside out (How to remove candles?) and look at their condition. Normal ones should have a slightly brick color, if they are wet, the candles will flood accordingly. It is necessary to clean and bleed the cylinders by idling the engine with the starter with the spark plugs turned out. If one cylinder is flooded, the problem is local (high-voltage wires, faulty spark plug, injector), all cylinders are flooded - a general problem (ignition coil, brains, oxygen sensor, fuel pressure in the rail).

- Next, check for the presence of a spark. To check it, check out the following article: How to check the spark?

Examination:

- If there is no spark on one cylinder, there is a faulty spark plug or high-voltage wire.

- If it is missing on two adjacent cylinders (1-4 or 2-3), then the problem is in the ignition coil or in the ECU.

- If there is no spark anywhere, the problem may lie in the ignition coil or ECU, in mismatched timing marks, or inoperative DPKV.

- If there are no problems with the presence of a spark, then the cause of the malfunction lies in the fuel supply.

Fuel supply

Two points are very important here:

- normal fuel pressure;

- working injectors.

If, when you turn the key into the ignition, you do not hear the fuel pump pumping, then that is where the problem lies. First of all, we measure the pressure in the fuel rail (How to measure pressure?) and draw the appropriate conclusions.

High pressure coupled with a malfunctioning fuel pressure regulator can instantly flood the engine.

Mass fuel flow sensor

Mass air flow sensor is a very important element of any injection engine. It is a plastic structure with a platinum thread inside. When the ignition is turned on, a small voltage is applied to it, which increases the temperature due to the high resistance. When the engine starts, the incoming air cools it, which causes the resistance to change, and according to Ohm's law, this affects the voltage. All this data is collected by the controller and processed, making a conclusion about how much air passes through the mass air flow sensor.

If the sensor malfunctions, important readings stop coming or are given in an incorrect form, which is why the engine control unit switches it to emergency mode. In addition, there are a number of signs that indicate a malfunction:

- Poor dynamics;

- Long engine start;

- Increased fuel consumption;

- Unstable or “floating” speed;

The dashboard diagram (Fig. 1.1) includes controls:

1 – lever-switch for headlight or turn signal modes.

2 – nozzle for blowing the front door glass.

3 – instrument cluster.

5 – button to turn off sound signals.

6 – button to turn off the alarm. Pressing the button causes the warning light and direction indicators to flash.

To repeat turning on the starter after a failed start attempt, you need to move the ignition key from position “I” to position “0”, and then again to position “II”.

8 – switch lever for windshield washer and windshield wipers.

9 – immobilizer sensor, transmits a special code from the code key through the immobilizer to the engine control unit.

10 – set of signal lights for the on-board control system. The complex contains (Fig. 1.2): 1 – oil level drop signal; 2 – low level signal in the windshield washer tank; 3 – low coolant level signal; 4 – door open signal;

11 – external lighting switch.

12 – block of keys for turning off fog lights, fog lights, heated rear window.

13 – trip computer, installed on some vehicles, designed to display one of the parameters: current fuel consumption (or average total fuel consumption), average speed, distance traveled, current time, time on the road.

15 – control lamp for anti-lock braking system (ABS). Installed in place of the plug, if equipped with an anti-lock braking system.

16 – airbag control lamp. If the pillow itself is present, it is installed in place of the plug.

18 – cover of the glove box (upper). To use the upper glove compartment while the lower glove compartment lid is open, press the upper lid lock lever. The lock lever is located in the niche of the lower glove compartment on top.

19 – side nozzle of the ventilation and heating systems of the cabin.

20 – glove box cover (lower). To open it, you need to press the lock handle to the handle. If the external lighting is turned on, a special illumination of the inside of the box will automatically work.

21 – magazine shelf.

22 – control panel for interior ventilation and heating systems.

23 – socket for audio equipment. It is planned to install audio equipment that meets international standards in size and mounting principle.

Error code: Check light on VAZ 2114 - reasons, what to do

Watch the video of testing the dashboard of a car here:

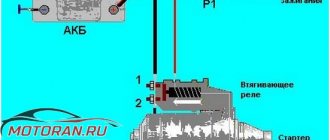

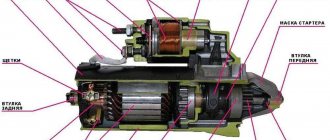

Starter failure

If all other system components are in order, then the reason for the inability to start may lie in the absence of a starter. Typical problems:

- poor contact at the terminals;

- the starter shaft bearing has failed;

- The solenoid relay has stopped working.

It should be noted: the location of the power terminals on the starter suggests the presence of moisture. Therefore, often the contact simply oxidizes, which leads to problems in the operation of the device. That is why you need to carefully examine the contacts. Then clean them and check the voltage. If it is missing, there may be a break in the wiring.

We recommend: Suzuki Vitara: performance features and prospects on the Russian market

When there is voltage, but the starter does not turn, it is often a problem with the bearings. To replace it, you will need a clean garage, as well as a special puller. This is the only way to dismantle it.

A little more often than a bearing, the solenoid relay fails. Sometimes it just jams - just tap it lightly with the key.

It is very simple to check the functionality of the retractor - just place the starter on the engine block and then touch the contact of the wiring relay connected to the positive terminal. If the starter starts spinning, it means the solenoid relay is in working condition. All of the problems listed above are typical and do not require any major repairs.

VESKO-TRANS.RU

Content

Obstacles to starting a car engine are divided into two main groups, depending on the degree of engine heating.

Since the engine has been shut down for less than 6 hours at an ambient temperature of 20°C for at least 3 hours at a temperature of -20°C, the engine crankcase oil temperature is the same as the ambient temperature. The methods for starting an engine with a fuel injection system are the same at any ambient temperature.

1. Open the hood by personally pulling the drive handle, locking it.

4. Use the dipstick to determine the oil level. This is required between the "MAX" and "MIN" characters.

3. Check the brake level.

4. and coolants.

5. Carefully inspect the engine and engine compartment. Carefully inspect for gasoline, oil, brake and coolant stains. Check wiring integrity. Check the suitability of the high-voltage wires in the ignition module connectors and on the spark plugs.

6. Turn on the ignition by turning the ignition key to position “I”. The gasoline pump will turn on. Do not close the hood (if the hood is covered with rain or snow), walk away. Start the engine.

It is better to close the hood if the engine starts running. Before doing this, it is better to inspect the engine again to make sure that fuel, oil, antifreeze and other sounds are leaking.

If the engine does not start, there are three main conditions:

The engine is warm, as they call it hot

Don't turn the starter, don't turn the key, VAZ 2115, 2114

The oil temperature in the crankcase is higher than the ambient temperature.

To begin, simply turn on the starter without touching the accelerator pedal. The engine management system will unassistedly set the fuel and ignition parameters required for starting.

If for any reason the spark plugs are "primed" during a failed test, use the cylinder "bleed" mode. To do this, fully depress the accelerator pedal and turn on the starter. There is no fuel supply, excess gas is removed from the cylinders by a stream of fresh air, and the spark plugs are dried. After cleaning, try rebooting as always.

If the engine does not start, there are three main conditions:

Troubleshooting to start accounting (software)

Malfunctions in the starter system occur when the starter is not operating properly. There are 5 main starter defects:

1. The starter is not cut. The reason is a violation of contact connections, shutdown due to another short circuit in the starter switching circuit, or a malfunction of the traction relay.

4.5. When the starter is turned on, the clicking noise is repeated. The reason is a failure of the holding winding of the traction relay, the battery is severely discharged, and the contacts in the starter circuit are weak.

3. The starter is cut, but its armature either does not rotate or rotates slowly. The reason is that the battery is discharged, the contacts are broken, the traction relay contacts are burnt, the commutator is dirty or the brushes are worn out, switching, which is called a short circuit in the windings.

4. The starter is cut off, its armature rotates, unfortunately, the flywheel remains motionless. The reason is the weakening of the starter to the clutch housing, damage to the flywheel or drive gears, slipping of the drive flywheel, breakage of the lever, drive ring on another buffer spring of the starter drive.

5. After starting the engine, the starter will not turn off. The reason is a malfunction of the freewheel mechanism, sintering of the contacts of the traction relay. If such a malfunction occurs, stop the engine immediately!

These faults require qualified intervention at a service station in different ways after arriving at the garage (see Chapter 9 “Electrical”). Previously, you could only check the degree of discharge of the battery using a voltmeter in the instrument cluster and the tightness of the contacts in the starter circuit.

Testing the ability to keep records (software) of ignition

Your vehicle is equipped with a Microprocessor Based Maximum Power Z (MPSZ) ignition system. A voltage of about 40,000 V is supplied to the high-voltage wires; of course, with a small current this is not life-threatening; a possible electric shock when checking the ignition system leads to lingering consequences. If you handle high voltage ignition wire, use thick rubber gloves or, in the latter case, insulated-handled pliers.

Phillips slots and screwdrivers, insulated pliers and tester.

Before checking the ignition timing set, place the shift lever in neutral and apply the parking brake.

1. When turning off the ignition, check the integrity and compliance of the high-voltage wires in the ignition module.

3.5. Disconnect the harness connector from the ignition module low voltage circuit block.

3. And check if the tester is turned on in low current (mA) mode, the low voltage circuit of the module is open by connecting test leads to terminals C and B of the unit.

4. If the ignition module low circuit is operating, to check the operation of the module high circuit and high voltage wires, check for spark at the spark plugs. Remove the high voltage wire from any spark plug. Insert the spark plug into the tip of the wire and press it with the iron part against the ground of the car. Turn the engine starter crankshaft.

5. If there is no spark, replace the high voltage wires with new ones. Of course, for testing you should not install a new one, unfortunately tested, “from a running machine”.

6. If spark does not appear after replacing the wires, replace the ignition module (see Chapter 9, Electrical Equipment). If there are sparks, unfortunately the engine will not start, replace the spark plugs with new ones. You can also try installing a new one, unfortunately tested "from a running machine" in the past.

7. If the engine does not start later, check the functionality of the complex engine management accounting programs (see “Troubleshooting complex fuel injection accounting programs”).