The gearbox in VAZ 2110 cars is one of the most involved dynamic elements. Because of this, the unit often becomes loose, which makes operating the car inconvenient. A shaking gear shift lever is a fairly common occurrence in domestic cars. There are two ways to combat this defect: constantly adjust the gearbox or make the rocker short-stroke - the process can be done independently. You can also purchase a gearbox repair kit from another VAZ model, which initially comes with a short-throw driveshaft.

What is so good about a short-stroke rocker? Firstly, it guarantees reliable operation of the gearbox over a long period of time. Secondly, the short-stroke version helps to increase the clarity of VAZ gear changes, including in the 2110 model. This is quite enough to make the operation of the power plant more comfortable, because smoothness, stroke and clarity of gear shifting are important for the gearbox.

We adjust the gearbox shifter on a VAZ-2110 with our own hands

The gearbox on the VAZ-2110 sometimes starts to act up. If you neglect the care and maintenance of this part of the car, you can get many problems with the operation of the gearbox. As a rule, these are inaccuracies in gear shifting, characteristic “knocking out” of the gear, crunching and clanging when manipulating the gearbox lever. Some car owners believe that all these symptoms indicate a gearbox failure.

A new model of the link from Priora for the VAZ 2110

New type of slide (Prior)

In general, I accidentally saw this miracle on the Internet, I wanted to find it and install it for myself. I bought parts from a 2014 Lada Priora, all assembled with levers and other fittings)

The clip is ten-size, the levers are completely similar to the old ones.

The most interesting thing is the rocker, the handle like on the new Priors and Grants with a manual transmission. In technical terms, it is similar to the viburnum wing, perhaps one to one.

It’s hard to say how she’s doing at work. But I would like to note right away that the reviews about this design are different, some are very negative!

Someone has some play between parts 17 and 20; apparently the metal bushing in the center (part 18) is in the way. It does not allow the metal discs (part 16) to be properly pressed against the plastic spacers (17) and the lever itself (20). Theoretically, if you sharpen it, there should be no more problems.

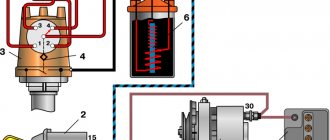

The scheme is Kalinov’s, but the essence is the same.

Let's go and see!

Why do you need a gearbox slide?

In fact, most often the gearbox is in good condition, but the rocker may fail.

You can replace the unit with a new one, or you can get by with proper adjustment of the rocker. Adjusting this element will help troubleshoot problems and make sure that the problem is related specifically to the gearbox linkage. It happens that a car owner simply begins to change one component after another without understanding the problem, wasting money and time to no avail.

The gearbox itself is designed to prevent gears from switching spontaneously . It happens that due to incorrect or erroneous adjustments, the entire transmission system begins to work incorrectly and may even fail. Therefore, you need to be able to adjust the gearbox rocker with your own hands, especially since this procedure is not complicated.

When does the rocker need adjustment?

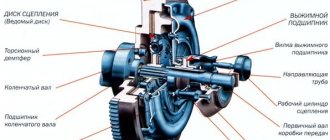

Gear shift mechanism.

The procedure for adjusting the gearbox linkage is recommended in the following cases:

- After the transmission on the car has been replaced or removed.

- When loosening the fixing clamps.

- If the cardan was changed.

- If the link starts to rotate on its hinge.

Although visually it may seem that the rocker is in place, even the slightest movement of the rocker can lead to incorrect operation of the gearbox. It happens that it is enough to tighten the link to the cardan by 1 mm, after which all functions of the gearbox will be restored.

Replacing rocker seals

Nothing frustrates a car owner more than traces of oil under the bottom while parked. The cause of this manifestation may be a worn out oil filter or a faulty oil seal.

When installing a new oil seal, you can see and evaluate the condition of the rocker pad, cardan and boot.

Before you begin disassembling all components of the car, you need to find out the reason for the leakage of the oil mixture. If the reason is not the oil filter, you need to make sure that the oil seal is in good condition. To do this, the car is installed on a platform or lift. If the work of replacing and installing a new oil seal is being carried out for the first time, previewing a video on this topic will be very helpful.

- Climb under the car and make a visual assessment of the boot. If oil leaks through the oil seal, the boot will reveal this and there will be traces of oil leaks on it;

- Having bent the boot, you need to get to the cardan. Disconnecting the driveshaft will open the way to the cuff;

- The sequence of removing the cardan is strictly from the lever to the rocker, the reverse order is prohibited;

- After dismantling the cardan shaft, access to the oil seal opens;

- To remove the cuff you will need a hook and spike;

- A seal that has become unusable is replaced with a new one. Garage repair gurus use a plastic bottle cap as an auxiliary tool for this;

- After installing the new oil seal, the unit is reassembled. In this case, the condition of each element is necessarily checked for wear, and if necessary, the part is also replaced.

Preparing to adjust the rocker

On an old car, it is better to lubricate the linkage mounting assembly with a penetrating compound in advance.

Before starting adjustment work, you need to prepare the place and carry out the following preparatory measures:

- The car needs to be parked in a pit.

- The handbrake must be tightened all the way.

- It is mandatory to install wheel chocks.

For a faster and better adjustment process, it is better to perform all work with an assistant. The process itself can occur in several ways.

First adjustment method

To adjust, you need to loosen the clamp connecting the rocker drive to the cardan.

This method is the simplest. In this case, the gearbox linkage is adjusted according to the reverse speed . First of all, you need to loosen the clamp, after which the reverse gear is engaged. Then you need to position the lever in the position you need. After this, the clamp is tightened and the operation of the entire mechanism is checked.

If you don't succeed the first time, you need to listen for knocks and crackles when switching . They must either decrease or increase. In accordance with this, you need to position the lever in the desired direction. If all manipulations do not lead to the desired effect, you need to resort to another adjustment method.

Second adjustment method

The gear shift lever should rest against the locking plate (in the photo it is made of light plastic).

This method is used if the first one did not lead to the desired results. When using it, you can more clearly position the gearshift lever. This method is as follows:

- The gearshift lever switches to first speed.

- The backstage clamp is completely loosened.

- Next, you need to turn the drive of the rocker itself counterclockwise until the lever rests against the reverse speed stop.

- The backstage clamp is tightened.

Tighten the clamp fastening nut, eliminating the shift of the rod during operation.

It happens that some VAZ-2110 cars do not have a plastic limiter retainer, so the adjustment in this case is carried out not in first gear, but in neutral.

Third adjustment method

This method is quite complicated , as it involves calculating the depth of the gearbox linkage to the cardan. Due to this, the position of the lever in the neutral position can be accurately calculated and adjusted. It happens that if the calculation is not accurate enough, all manipulations only lead to the appearance of rattling when changing gears.

If adjustment by any of the above methods does not lead to the desired results, several options are possible to solve the problem:

- Carry out diagnostics at a service station to make sure that the problem is in the gearbox linkage.

- You can replace the gearbox linkage.

- You can contact specialists who will adjust the slide themselves.

Self-adjustment of the rocker on a VAZ 2110. Adjustment of the gearbox rocker with your own hands

To get rid of all this, you need to carry out a simple procedure for adjusting the gearbox rocker, especially since adjusting the rocker will take you no more than half an hour.

The gearbox slide is necessary to prevent random switching of gears due to the simultaneous movement of the sliders. Often, the entire transmission suffers from an incorrectly adjusted rocker, and as a result, you are at risk of malfunctioning the entire gearbox. In our previous articles, we have already talked about this detail several times, for example, in the article: About how to install a short-stroke rocker on a Lada Priora, as well as in the article: Installing a short-stroke rocker on a VAZ 2109. In addition, the issue of engaging gears and gearboxes is addressed in this article.

Adjusting the gearbox slide requires the presence of an assistant, in which case the result, and the work itself, will be of better quality. It is fashionable to adjust the slide in several ways; below we will talk about each of them in more detail.

How to adjust the rocker on a VAZ 2110 with your own hands

Before adjusting the gearbox linkage, it is necessary to perform a number of preparatory work:

- Drive the car into the pit.

- Tighten the handbrake and install the wheel chocks.

Method No. 1 - adjusting the rocker according to the rear speed.

- Loosen the clamp.

- Engage reverse and position the lever as you would like it to be in that position.

- Then tighten the clamp and check how the rocker works, whether you are satisfied with the current position of the lever and the operation of the rocker.

Method No. 2 - adjusting the rocker at first speed.

This method is used, as a rule, when the first method did not produce results.

- Turn on first speed.

- Loosen the rocker clamp.

- Turn the rocker drive counterclockwise until the gearshift lever begins to rest against the plastic reverse speed stop.

- Tighten the clamp and check how everything works.

Method No. 3 - adjusting the scenes in neutral.

If you do not have a plastic stopper, the adjustment is made in neutral gear.

To adjust the neutral position of the gearshift lever, you need to accurately calculate the depth of the shift of your gearbox to the driveshaft of the VAZ 2110. Sometimes such manipulations result in the appearance of annoying rattling of the lever.

If adjusting the rocker does not lead to anything and there is still a problem with switching, replace the rocker completely or ask for help from specialists.

Fighting the ringing

Typically, a ringing sound appears after adjusting the gear shift lever. To correct this drawback, you need to install a spring to hold the lever. The development of mechanical engineering makes it possible to replace the parts of the VAZ 2110 backstage with similar, but more advanced ones. For a VAZ car, the Kalina rocker is ideal.

In this case, the cardan from the new model is modified to be 20 mm longer than on the ten. This sound is directly related to the part itself; the Kalina rocker has no play, and all the vibration is transmitted into the car interior, to the gear shift lever itself. The easiest way to get rid of rattling is to install a spring.

Self-adjustment of the rocker on a VAZ 2110. Adjustment of the gearbox rocker with your own hands

Author: ides · Published 07/12/2016 · Updated 07/12/2016

“> The gearbox linkage, like everything else in a car, requires care and timely adjustment. misadjusted gearbox linkage can cause discomfort while driving. For example, the gear knob may rattle, the gear shift may become inaccurate, the speeds may “knock out” from time to time, and the lever itself may begin to “play.”

To get rid of all this, you need to carry out a simple procedure for adjusting the gearbox rocker, especially since adjusting the rocker will take you no more than half an hour.

The gearbox slide is necessary to prevent random switching of gears due to the simultaneous movement of the sliders. Often, the entire transmission suffers from an incorrectly adjusted rocker, and as a result, you are at risk of malfunctioning the entire gearbox. In our previous articles, we have already talked about this detail several times, for example, in the article: About how to install a short-stroke rocker on a Lada Priora, as well as in the article: Installing a short-stroke rocker on a VAZ 2109. In addition, the issue of engaging gears and gearboxes is addressed in this article.

Adjusting the gearbox slide requires the presence of an assistant, in which case the result, and the work itself, will be of better quality. It is fashionable to adjust the slide in several ways; below we will talk about each of them in more detail.

How to adjust the rocker on a VAZ 2110 with your own hands

Before adjusting the gearbox linkage, it is necessary to perform a number of preparatory work:

- Drive the car into the pit.

- Tighten the handbrake and install the wheel chocks.

Method No. 1 - adjusting the rocker according to the rear speed. - Loosen the clamp.

- Engage reverse gear and position the lever as you would like it to be in this position.

- Then tighten the clamp and check how the rocker works, whether you are satisfied with the current position of the lever and the operation of the rocker.

Method No. 2 - adjusting the rocker at first speed.This method is used, as a rule, when the first method did not produce results.

- Turn on first speed.

- Loosen the rocker clamp.

- Turn the rocker drive counterclockwise until the gearshift lever begins to rest against the plastic reverse speed stop.

- Tighten the clamp and check how everything works.

Method No. 3 - adjusting the scenes in neutral.If you do not have a plastic stopper, the adjustment is made in neutral gear.

To adjust the neutral position of the gearshift lever, you need to accurately calculate the depth of the shift of your gearbox to the driveshaft of the VAZ 2110. Sometimes such manipulations result in the appearance of annoying rattling of the lever.

If adjusting the rocker does not lead to anything and there is still a problem with switching, replace the rocker completely or ask for help from specialists.

Source: VAZ DIY repairs

Box device

The operating principle of the device is as follows:

- To change gears, the main shaft operates in the box. It consists of a block of gears that are constantly in mesh with gears from 1st to 5th gear (forward movement of the car).

- The second shaft is equipped with final drive gears, which also includes synchronizers. They are responsible for the forward movement of the driven gears. The oil pan and bearing are in the same place.

- The “ten” is attached to the two-satellite differential through the flange of the gearbox of the driven gear main gear.

- The drivetrain consists of a shift knob, ball joints, shift lever, joysticks, shift mechanism and direct shift mechanism.

- The purpose of the jet lift is to prevent speed deviation. Its ends are attached to the bracket and the engine.

How to adjust the rocker on a VAZ 2110 with your own hands

Often, inexperienced car owners mistake problems with the clutch for a failure of the gearbox. Do not panic ahead of time, it is important to correctly diagnose the problem; if the cause of the problem is the rocker, you can fix the problem yourself.

Experience in servicing the VAZ 2110 allows us to say that problems with the rocker require replacement or major repairs of the part in extreme cases. Most often, the situation is saved by simple adjustment.

You should not be afraid when it becomes clear that repair work, replacement, or adjustment of a car part is inevitable. Almost every car owner can adjust the VAZ rocker with his own hands.

Symptoms of a malfunctioning rocker

There are certain signs indicating that it is the gearbox linkage that has become unusable, and not the transfer case itself.

The most common signs:

The first gear is driven correctly, but after a while the reverse gear is set independently;

As soon as the listed symptoms, even one of them, are noted while driving a car, you need to contact the service to fix the problem. If experience and desire allow, you can fix the breakdown yourself.

The most common symptoms of a link failure and possible cause:

- The play in the gearbox lever can be clearly felt: the cause could be physical wear of the linkage, the problem can be solved by completely replacing the part.

- The box slide rings when gears are changed: sometimes the sound indicates a poorly performed repair or a factory assembly defect.

- Speeds are switched with great effort: adjusting the VAZ 2110 rocker will fix this; if the problem persists, you will need to replace the element.

- When you engage the first gear, the lever shifts to reverse gear: the reason is precisely in the gearbox, a mandatory replacement is required. The situation can be corrected by a repair kit, but this depends on the severity of the damage or the detected wear of the assembly elements.

- When the engine is running, strong vibration is transmitted to the gearshift knob: the hinges need to be checked, the cause could be play.

Gearbox adjustment

It is not always necessary to remove the box to adjust its operation. However, if the gearbox bearings need to be replaced or other repairs are required, simple adjustments will not be sufficient.

- Recently, the main shaft bearings on the VAZ 2110 have been replaced or other repairs have been carried out with the obligatory disassembly of the gearbox;

- One of the gears keeps going out;

- The pace of change is harsh, bad, or starts right away.

If you encounter one of these situations, adjustments will be inevitable. Although this is better than disassembling and completely repairing the gearbox. This operation is performed as follows:

- From the bottom of the car you need to find the nut and bolt that tighten the tape that holds the transmission rod together. You don't need to remove it completely, just loosen it a little.

- Using a regular screwdriver, slightly move the grooves on the tie rod apart, and also increase the clearance in the clamp. This will make it easier to shift the knob to the shift knob. The handle should be in the neutral position.

- Remove the cover from the gear shift knob.

- Install the lever as shown in the template - the template is located in the window of the rear gearbox lock lining. Then the lever axis stop is inserted into the existing template groove. It should be pressed in the transverse direction, but not with great force.

- The axial play of the rod in the rear direction is now adjustable, in addition, the axial play is adjusted by turning to the left.

- The clamp is set in place, leaving a gap of a few millimeters to the end of the strip. The clamp is now properly tightened with the screw.

Adjusting the backstage. Sequence of procedure

On a VAZ 2110, the adjustment of the backstage can be repaired in a regular garage; you just need to be patient, free time and the participation of a caring friend.

How to adjust the VAZ 2110 rocker if signs of a malfunction have just begun to appear:

- It is necessary to set the gearbox lever to first gear. It will be difficult to do this, but it must be done;

- It is most convenient to inspect the car on a lifting mechanism, which will provide access under the car. It is necessary to secure it with a handbrake and locking objects installed under the wheels;

- The box should remain engaged in first gear;

- Open the engine compartment and try to find the clamp that holds the rocker. To do this, you need to get close to the transfer case and reduce the clamp pressure;

- As soon as the clamp is loosened, perform the next adjustment step - move the gear shift lever to the left as much as possible. This must be done without jerking; if the movement is chaotic, the slide will come off;

- With the gearbox lever in the maximum left position, tighten the clamp;

- Often it is enough to move the link in relation to the cardan by a few millimeters.

By adjusting the rockers, it is possible to assess the degree of wear of the driveshaft; it is better to replace it if severe wear is noticed.

Backstage 2110: what you need to know

So, the shifter on a VAZ 2110 often makes inexperienced drivers think that the gearbox itself has failed. In fact, in the vast majority of cases, the VAZ gearbox linkage needs adjustment or repair. For this reason, it is important to know what symptoms and signs indicate a faulty yoke.

First of all, you should pay attention to the following:

- One or more gears do not engage or are difficult to engage;

- gears do not turn off after switching on or turn off with force;

- instead of engaging one gear, another is engaged (for example, instead of the first, reverse);

If such signs are noticed, it is usually not the transmission. This means that you should not rush to start diagnosing and troubleshooting the box itself. As a rule, problems can be solved by adjusting and servicing the rocker, which involves using a VAZ 2110 rocker repair kit. In extreme cases, a badly worn rocker needs to be replaced.

Let's get back to the adjustments. In fact, adjusting the VAZ 2110 rocker is not a complicated procedure, but it will require attention and patience. It happens that adjustment is required in several approaches, since it is not always possible to find a good position the first time.

To adjust the link, you will need to perform the following steps:

- First of all, the car needs to be driven onto a pit or overpass. Then you will need to put the car on the handbrake and engage first gear.

- Next, without turning off the gear, you will need to find the clamp that secures the rocker, and then loosen this clamp.

- Then, you should move the lever from the passenger compartment to the left as much as possible. In this case, you cannot move the lever both backwards and forwards. The fact is that the slide may well jump off.

- Now you need to get into the car and then tighten the clamp. In some cases, it is enough to move the rocker a few millimeters in relation to the cardan, after which the gearbox will work normally again, and gear shifts will return to normal.

Finalization of the scenes of the VAZ 2110

Owners of domestically produced cars often wonder about the possibility of improving the operation of the gearbox by installing a short-throw shifter instead of the standard one installed during assembly.

The short-throw rocker is the result of a VAZ garage tuning. Replacement allows you to improve the efficiency of the box, gear shifting is carried out in a more precise mode, and whether to make this replacement or not is the choice of the car owner.

Changing the type of rocker does not require dismantling the standard part. Replacement is carried out in the sequence described below:

- From the outside, disassemble the ball joint;

- The metal ring of the support gently opens, the plastic legs move apart;

- The support ball rolls out;

- Disconnect the rod from the support, then weld a fragment of a tube, a strong piece of metal, to it, to the rod;

- When making adjustments, it is necessary to raise the hinge with the hook, this will prevent the switching on the wrong speed that was selected.

You can watch the process in more detail in the video:

Changing the type of gearbox link will result in a harder gear shift, but it will also become clearer.

Technological features of long-stroke and short-stroke scenes, as well as their advantages and disadvantages:

Adjustment

You still need to engage first gear and drive onto the overpass. Naturally, put the car on the handbrake and put wheel chocks under the wheels. Don't turn off first gear!

From below, find the clamp that secures the rocker and loosen it. Returning to the car, you need to move the lever to the left as far as you can. You cannot move the lever back or forward; the link may come off.

Go back under the car and tighten the clamp. Sometimes it is enough to move the rocker relative to the cardan by a few millimeters, and the gearbox will work perfectly again, gear shifts will occur as expected.

Tuning

Many VAZ 2110 car owners, even having purchased a completely new car, strive to change the scenes. This can make it more comfortable, but only if done carefully.

The fact is that the short-stroke rocker is, in fact, a homemade product, a modification. If you have a short-throw shifter, the gearbox wears out less, and in general this is not bad for the gears - they engage more clearly.

In order for the short-stroke rocker to replace the standard one, it does not have to be completely removed. It is enough for the ball joint to be disassembled from the outside. It is necessary to unclench the metal ring of the support and spread the plastic legs so that the ball comes out.

Next, you need to disconnect the rod from the support and weld a small piece of pipe to the rod, as well as a piece of durable sheet metal. Do not forget to lift up the hinge, which has a hook, to prevent the gears from being engaged by mistake.

Although the short-throw rocker requires more effort to engage, it increases the smoothness and clarity of gear engagement. But, in principle, choosing which is better for him - short-stroke or full-time - is the right of every VAZ 2110 owner.

Repair or replacement

Before deciding whether repair, adjustment or replacement of the link is necessary, it will have to be disassembled.

- Remove the cover on the gear shift knob;

- The machine must be installed on a jack or on an overpass (pit);

- Remove the front console, which is bolted on;

- Remove the rocker by unscrewing 6 bolts.

During this procedure, carefully inspect all parts. You definitely need to bend the boot and inspect the condition of the support, cardan shaft, and oil seal.

It may be necessary to use a rem. kit, and perhaps a more complex repair is needed.

If the bushing is deformed, it needs replacement. If the cardan has play, as well as if the hole in the lever axis is worn, a complete replacement of the link and repair belt is necessary. the kit clearly won't help.

The reasons why the gearshift lever may dangle and play are discussed in this material: https://vazweb.ru/desyatka/salon/boltaetsya-rychag-kpp.html

It happens that the rocker pad is to blame for the rattling noise when changing gears. Replacing a pillow is a simple operation, but can be beneficial.

Backstage repair

In the case where you plan to adjust the VAZ 2110 rocker with your own hands, completely replace or repair it, you will need to completely disassemble the unit.

This is done like this:

- The casing is removed from the shift lever;

- The car is placed on a hill or raised on a jack;

- The front console is dismantled;

- The rocker is removed; in the VAZ 2110 it is secured with 6 bolts;

- When disassembling the unit, evaluate the wear of each element;

- An overview of the support, cardan and oil seal can be obtained by carefully bending the boot.

By visually assessing all the parts of the unit, you can decide on the course and sequence of repair actions.

- For repairs and adjustment of the rocker, only a repair kit is enough;

- A deformed bushing requires mandatory replacement;

- It is wise to assess the degree of wear of the lever axis bore;

- If play in the cardan is detected, the link will need to be completely replaced;

- In many cases, extraneous sounds are caused by the rocker pad; replacing it is not difficult even for a novice car enthusiast.