The domestic SUV VAZ-2121, also known as the legendary Niva, has been tirelessly traveling around the expanses of our vast homeland and beyond its borders since 1977. Currently, this car not only has not lost its popularity, but on the contrary - the demand of car enthusiasts for this miracle of the automotive industry is only growing every year.

Channel PROGRAMMER'S DIARY

The life of a programmer and interesting reviews of everything. Subscribe so you don't miss new videos.

Why did the Niva become such a popular car? It's simple. The car's high seating position, all-wheel drive, ease of maintenance and relatively cheap prices for spare parts - that's the whole secret. Fishing, hunting, travel, expeditions and even sports racing - all this is the nature of the Niva.

You will be interested: VAZ 2114 - replacing steering tips: which ones are better to install, how to check for malfunctions

Since 1994, serial production of the VAZ-21213 model under the name “Taiga” began.

This VAZ model is equipped with a 1.7-liter carburetor gasoline engine, a five-speed manual transmission, and a contactless ignition system. A Solex 21073 carburetor is installed on the Niva. In the modern world, when progress does not stand still, a carburetor under the hood of a car, and even an SUV, looks sad. When buying a used car, most motorists prefer to choose an injection version rather than a carburetor. And today's youth look at the carburetor in surprise, completely not understanding what it is. But if a person has at least a little understanding of technology, then understanding the essence of the Solex 21073 carburetor will not be a problem. It is enough to familiarize yourself with some information.

The design of the Solex 21073 carburetor on the Niva

You may be interested in: How to specify the path to the game on Steam? Adviсe

This mechanism is a device for mixing the fuel-air mixture. This mechanism is very simplified, unlike the injector. The carburetor consists of only two main parts, one of which is the body and the other is the cover. The carburetor also includes a float chamber, a pump, and an economizer, which is responsible for regulating the fuel supply in order to save it. Inside the housing there are two fuel chambers and diffusers in which a fuel-air mixture is formed. On the carburetor cover there are special fittings for supplying gasoline to the carburetor and studs for attaching the air filter. Also in the cover of the Solex 21073 carburetor there is a needle valve for the float chamber. With the help of these parts the level of fuel consumption is regulated.

You might be interested: What is paintwork in a car? Definition, thickness and features

An air damper is installed inside the carburetor, which mechanically regulates the air supply to the chambers. As you can see, the Solex 21073 carburetor on the Niva has a fairly simple design. With proper care, it will not cause problems for the car owner and will not let him down on the road.

Idle system

In some situations, engine operation must be ensured even when the car is in neutral, when the speed is too low. At such a moment, the vacuum is insufficient and fuel will not be able to pass through the main metering chamber. A forced idle system is provided specifically for this purpose.

To do this, air is supplied through the main idle fuel jet into the first chamber. The fuel will then flow to the idle fuel jet. The air also passes through a special jet through a separate channel. This design allows the engine to operate even at low speeds, and when the throttle valve is opened, the power mode economizer begins working, which is considered as a transition system.

However, the system has a number of disadvantages when coasting:

- When the speed decreases by releasing the gas, fuel consumption continues;

- When switching to neutral gear, it increases completely.

Especially for this purpose, the calibration data also includes an EPHH, which turns off the fuel supply when coasting. Its operation continues until the speed drops to 1200 rpm and turns off when the throttle is opened. But when the car is stationary, it does not work.

Operating principle

As already mentioned, the Solex 21073 carburetor on the 1.7 liter Niva mixes gasoline with air and, as a result, the prepared fuel-air mixture enters the engine, where it burns. The driver starts the engine and closes the choke independently. The fuel pump pumps gasoline into the carburetor's float chamber. The amount of gasoline in this case depends on the position of the needle valve. From the float chamber, gasoline enters the nozzle, and then directly into the mixing chamber. At the same time, both cameras will start working only under heavy load on the engine. For example, if the driver sharply increases the speed by pressing the gas pedal. The engine idle mode is maintained by a solenoid valve. Thanks to this, the engine does not stall and fuel is saved at idle.

Purpose, diagram, structure and principle of operation of the VAZ 2107 carburetor

When setting up the VAZ 2107 carburetor, you need to adjust the starting device yourself. It is designed to confidently start a cold engine. When properly adjusted, the mixture is twice as saturated with fuel as when normally feeding a hot engine.

Let's figure out how the trigger mechanism works. By pulling the choke lever, the driver brings the starting device into a cocked state. The following actions occur:

- The three-arm lever is “cocked” with a cable counterclockwise;

- The telescopic rod is activated;

- The rod turns the air damper.

- The second arm of the lever presses on the throttle valve axis of the first chamber.

- The air flow damper closes completely. The throttle valve of the first chamber is slightly open for starting, creating a starting gap

Turn the choke lever to the closed position. In this position the device is turned on.

To adjust the gap to this range, you need to bend the drive rod on the throttle valve.

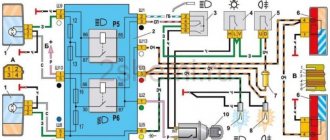

Picture 1

Now the rod has pulled the rod along the slot, and as a result the damper opens. Gap “A” should be 5-5.4 mm.

Figure 2

Setting up a VAZ 2107 carburetor with your own hands necessarily includes adjusting the starting device. Let us remind you that it serves to confidently start a cold engine. To do this, the mixture is twice or three times more saturated with fuel than when normally feeding a hot engine.

The starting device for carburetors of the 1107010 family operates at a frequency of 1500 rpm, that is, at the manufacturer’s recommended starting frequency for a cold engine.

We explain the mechanism of action of the starting device. By pulling the “choke”, the driver seems to bring the starting device into a cocked state. Wherein:

- The three-arm lever is “cocked” with a cable counterclockwise;

- Favors telescopic traction;

- The rod, in turn, rotates the air damper through a lever.

- The second arm of the lever presses on the axis of the throttle valve 1 of the chamber.

- The air flow damper is now completely closed, the throttle valve of chamber 1 is slightly open for starting, creating a starting gap

Turn the choke lever until it closes. The device is now “cocked”.

To bring it into this range, the drive rod on the throttle valve is bent.

Now the rod has pulled the rod along the slot, and as a result the damper opens. Gap “A” is 5-5.4 mm.

How to set idle speed on a VAZ 2107

First you need to make sure that the ignition system is configured correctly, all wires are working properly and the engine is completely warmed up.

For this:

- We tighten the mixture “quality” screw to maximum speed (counterclockwise), while the mixture is enriched with fuel;

- By rotating the “quantity” counterclockwise, we set an even higher frequency on our own.

- We carry out a “quality” check: is it possible to increase the speed further?

The meaning of this operation is to increase the “quality” at a constant “quantity” to 850-900 rpm.

You can estimate the speed using an electronic tachometer, or by ear if you are skilled, or using the dashboard tachometer.

The next step is to regulate the air damper drive.

If you do not pay attention to the position of the drive, the machine may stall. To do this, you will need a simple slotted screwdriver and a 7 mm open-end wrench.

The figure shows the position of the damper with the “suction” recessed and extended.

To adjust, do the following:

- the “suction” is recessed;

- We unscrew the rod fixing screw with a slotted screwdriver (the spring pushes it out vertically)

- Tighten the screw;

- We check the valve movement.

Read more: High fuel consumption VAZ 2106 carburetor causes and solutions instructions with photos and videos

We adjust the throttle valve drive (“gas”).

If this drive is not configured correctly, the acceleration dynamics and throttle response of the engine deteriorate. This setup must be done with an assistant.

You will need an 8-mm open-end wrench, a screwdriver, a flashlight and a caliper.

We will completely “drown” the “choke” or air damper drive.

- Now your assistant presses the gas pedal all the way to the floor. This opens the throttle valve completely, as shown below; to be sure, you can illuminate the first chamber with a flashlight. After releasing the pedal, the damper should completely close the first chamber without gaps.

To adjust, use a caliper to measure the length of the rod; it should be exactly 8 cm. By rotating the tips, we “adjust” the length of the rod to this size by unscrewing the “locking” nuts.

After this, we put the rod in place and repeat the test. Modern rods are often made of very poor plastic, which shrinks. Therefore, you need to check the “break-in” of the traction after a week or two.

You may not know how to adjust the carburetor of a VAZ 2107, but anyone can set the length of the rod.

We have considered only a few possibilities for adjusting the carburetor with our own hands. In general, there is an entire profession called “carburetor mechanic,” which implies full mastery of this necessary and complex technology. It is simply impossible to describe all the nuances of this process in one article. But we hope that the basic principles were clear and useful to you.

The “seven” was equipped with various modifications of the DAAZ 2107 carburetor (Dimitrovgrad Automobile Unit Plant). They are all similar in principle and differ only in some design details.

Diagram of the VAZ 2107 carburetor structure: (1 - screw for adjusting the stroke of the accelerator pump intake valve; 2 - carburetor cover; 3 - fuel jet of the transition system of the second chamber; 4 - air jet of the transition system; 5 - air jet of the econostat; 6 - fuel jet of the econostat; 7 — main air jet of the second chamber; 8 — emulsion jet of the econostat; 9 — pneumatic drive of the throttle valve of the second chamber; 10 — small diffuser; 11 — jets; 12 — discharge valve of the accelerator pump; 13 — accelerator pump nozzle; 14 — air damper; 15 - main air jet of the first chamber; 16 - starting device jet; 17 - automatic starting device; 18 - idle air jet; 19 - idle fuel jet; 20 - fuel supply needle valve; 21 - fuel filter; 22 - fuel supply fitting ; 23 — float; 24 — screw for factory adjustment of the idle speed system; 25 — main fuel jet of the first chamber; 26 — adjusting screw for the quality of the working mixture;

27- adjusting screw for the amount of carburetor working mixture 2107-1107010; 28 — throttle valve of the first chamber; 29 — carburetor body; 30 — throttle valve of the second chamber; 31 — throttle body; 32 - emulsion tube; 33 — main fuel jet of the second chamber; 34 — accelerator pump bypass jet; 35 — accelerator pump inlet valve: 36 — accelerator pump drive lever; 37 - carburetor pneumatic valve 2140-1107010-70.) Purpose.

The purpose of the carburetor is to prepare the gasoline-air mixture in the required proportion and supply it to the engine cylinders. The quality of engine operation, power output, and service life depend on how correctly the ratio between fuel and air is maintained, and how well the dispersion is mixed.

Design and principle of operation. The schematic diagram of the VAZ carburetor is conventionally divided into three structural elements:

- Cover with outlets for hoses; The structure of the VAZ 2107 carburetor cover: (1 - float axis; 2 - needle valve; 3 - float; 4 - gasket; 5 - trigger diaphragm with rod; 6 - spring; 7 - adjusting screw; 8 - trigger cover; 9 - idle fuel jet; 10 — solenoid shut-off valve; 11 — plug; 12 — carburetor cover; 13 — fuel filter; 14 — air damper; 15 — fuel supply pipe; 16 — air damper axis with lever; 17 — control lever fixation ball air damper; 18 — air damper control lever; 19 — lever axis; 20 — bushing for fastening the air damper drive rod)

- The housing in which the float chamber and chambers with diffusers are located; Structure of the VAZ 2107 carburetor body: (1 - accelerator pump diaphragm; 2 - accelerator pump drive lever; 3 - cover; 4 - accelerator pump drive cam; 5 - power mode economizer cover; 6 - economizer diaphragm; 7 - economizer fuel nozzle; 8 — economizer valve; 9 — check valve of the accelerator pump; 10 — accelerator pump nozzles with a fuel supply valve; 11 — nozzles; 12 — main air jets with emulsion tubes; 13 — main fuel jets; 14 — bracket for fastening the air damper drive rod shell; 15 — adjusting screw of the second chamber; 16 — stopper of the adjusting screw; 17 — stopper cap; 18 — adjusting screw for slightly opening the throttle valve of the first chamber; 19 — axis of the throttle valve of the first chamber with drive levers; 20 — locking lever of the second chamber; 21 — lever spring locks; 22 — throttle axis of the second chamber with a lever; 23 — throttle valve of the first chamber; 24 — throttle valve of the second chamber; 25 — plug for adjusting screw of mixture quality (composition); 26 — return spring of the throttle valve drive lever of the second chamber; 27 — adjusting screw for the quality (composition) of the idle mixture; 28 — carburetor body; 29 — adjusting screw for the amount of idle mixture; 30 - electrical wire of the limit switch of the forced idle economizer; 31 - carburetor heating unit)

- The bottom where the throttle valves are located.

Float mechanism

On Niva, the float chamber in the carburetor consists of two sections located on the sides of the chambers for preparing the fuel-air mixture. In general, the float mechanism consists of two floats made of hard rubber, mounted on a special lever, which looms on an axis pressed into the cover of the Solex 21073 carburetor. The essence of the float mechanism is to regulate the fuel supply.

Setting the level in the float chamber

So, we looked at the Solex device. Adjusting the carburetor will help set the optimal mode when the engine will operate as efficiently as possible and at the same time fuel consumption will not be too high. First you need to start and warm up the engine a little. Then remove the fuel hose and carburetor cover. Then disconnect the suction cable and twist the cover off the device.

It must be removed as smoothly and carefully as possible so as not to damage the float. Then use a ruler or caliper to measure the distance in each chamber. You need to measure from the mating surfaces to the edge of the gasoline. This size should be about 24 mm. If it is larger or smaller, then the parameter is adjusted by bending the float. Then the device is reassembled, the engine is started and it is warmed up.

Operating principle of the main dosing chamber

During the combustion of the fuel-air mixture in the engine cylinders, air enters the chambers through the air filter. As the air flow increases, pressure is exerted on the nozzles. As a result, fuel rises from the wells into the atomizer. At the same time, air is fed through an air jet from above into the emulsion tube. In the chamber, the fuel is mixed with air and goes into the carburetor channels, where it is directed further into the engine under high pressure. This is the operating principle of almost all Solex carburetors.

Main dosing systems

The first and second chambers are equipped with diffusers. There is one large and one small element. Spray devices are also made together with small diffusers. The latter are connected through channels to the emulsion wells, and they communicate through one channel with the float chamber. To ensure that gasoline flows in certain portions, the main fuel jets are located below in the emulsion wells. These same wells have special tubes. Each of them is equipped with an air jet at the top. Air is supplied to them from the neck of the device.

Diagnostics of malfunctions of the Solex 21073 carburetor on a Niva

Any mechanism is subject to physical wear and tear during its operation. Likewise, the Solex 21073 carburetor on the Niva requires periodic inspection and maintenance. If any malfunction is detected, it is first necessary to carry out diagnostics. The causes of carburetor malfunction can be different. This includes refueling with low-quality gasoline and a dirty air filter. As a result, small particles of dirt enter the carburetor chamber. This results in problems in the system in the form of increased fuel consumption and poor operation of the mechanism as a whole. There is no need to rush to replace the carburetor with a new one. Simple cleaning and adjustment will help eliminate these symptoms.

Advantages and disadvantages of tuning

The Solex carburetor is assembled from standard parts and assemblies from various manufacturers and is not subject to individual adjustment. But the cast body, made of aluminum alloy, diffusers, damper jets, as well as fasteners have unprocessed burrs, protrusions, and roughness. The task of tuning is to remove all obstacles to the movement of the air-fuel mixture by grinding, polishing channels and parts with which the fuel flow comes into contact, as well as modifying diffusers and adjusting jets in accordance with the individual requirements of the car enthusiast.

To perform the above work, it is necessary to remove the carburetor from the engine intake manifold and remove the cover. It is necessary to achieve complete alignment of all holes of adjacent removable parts. This is done using a scraper or file.

You need to remove the air damper and replace its round head screws with flat head screws. Then drill out the holes a little to “recess” the protruding parts of the fasteners. This will reduce hydrodynamic resistance during the passage of the air-fuel mixture. It is advisable to replace the needle valve with a valve with a rubber tip to prevent gasoline overflow.

All carburetor diffusers need to be polished, the technological ebbs on the bridges must be cut down and given a more streamlined shape. The flow rate of the fuel mixture in the mixing chamber reaches 120 meters per second, and any roughness will impede the flow of air.

Tuning the carburetor not only affects the throttle response of the engine, increases its power, but also significantly increases fuel consumption. Before assembling the mechanism after modification, it is recommended to wash all its parts with a special liquid for cleaning the carburetor, and then blow out the holes with compressed air.

The Solex carburetor is one of the best engineering developments successfully used on Russian Niva SUVs. Carburetor engines are repairable, easy to maintain and reliable. Tuning can significantly improve engine performance and increase its efficiency.

How to restore carburetor operation?

To clean or adjust the Solex 21073 carburetor on the Niva, it must be removed. We remove the air filter housing and remove all the tubes and wires that interfere with getting the mechanism to the surface. Unscrew the nuts and remove the carburetor.

It is best to disassemble it on a table in a well-lit and ventilated area. There are many small parts in the carburetor, therefore, in order not to get confused about what and where, it is recommended to put all the parts in order. You may have to purchase a Solex 21073 carburetor repair kit for the Niva at an auto parts store. It will help you quickly fix the breakdown, and besides, it is inexpensive. Wash the carburetor with special means or regular gasoline.

Adjusting the Solex 21073 carburetor on a Niva

Adjust the carburetor on site after washing and installing it. At the bottom of the Solex 21073 carburetor there is a screw that controls the fuel supply level. Using a flat-head screwdriver, turn this screw until it stops with the engine off. Then unscrew the screw five turns back and start the engine. Next, the screw must be tightened and unscrewed until engine operation becomes uniform. After the engine speed is normalized within 900, the screw is set one turn all the way.