Hello, dear motorists! A modern person, for whom a car has become a reliable and indispensable assistant, should have at least a general understanding of its structure. At a minimum, you need to know the symptoms of major malfunctions and it is imperative to master the skills of eliminating the simplest malfunctions.

Although the concentration of service centers and private workshops is constantly increasing, it may happen that the nearest one will be too far away and you will have to rely only on your own strength.

If one of your fellow motorists asks what the generator belt tensioner pulley is for and why it is so important to monitor its condition, then this person really does not understand what they are talking about.

The heart of a car is its engine. If anyone thinks that the engine in a car only serves to enable it to drive, then they are very mistaken. The functions of the motor are much wider.

The first thing we see when we lift the hood is the many different devices with which the engine is “hung” on all sides. It is interesting and necessary to know why all this is installed in the engine compartment.

Alternator belt roller - spool, which is very expensive

Alternator belt tensioner

In addition to the fact that the internal combustion engine is the source of the force transmitted to the wheels, it ensures the functioning of numerous machine devices and its own systems.

At the front of the engine, the crankshaft necessarily has a one-, two-, or three-row pulley, which is connected via a soft belt drive to equipment such as:

- generator;

- cooling system pump;

- gas distribution mechanism;

- air conditioner;

- power steering.

Each of these devices performs its own function, but most of them, like the motor, cannot do without a generator.

Stable operation of the generator as a source of energy is possible only if the belt tension is sufficient. Most foreign and domestic cars, especially new models, have a special device - a generator belt roller, which regulates the degree of tension of the belt drive.

There are several modifications of such devices. One of the simplest is a roller whose center is shifted. When the eccentric rotates, the belt is tensioned and secured using a bolt.

Another option is to install the roller on a movable bracket and tension it with a bolt. Regardless of how the generator belt tensioner roller performs its task, it is necessary to monitor its condition and carry out repairs at the slightest suspicion of a malfunction.

Replacing the tension roller of the alternator belt is a matter of five minutes

The generator belt tension roller has a very simple structure, and its most important part is the bearing. At every opportunity when a belt is loosened or replaced, the condition of the bearing should be diagnosed.

When rotated by hand, a serviceable roller spins quietly, without snagging, jerking or play. If the roller life is exhausted, it should be replaced. This is not difficult to do in a garage with a minimal set of tools.

To replace the tension roller, you must perform the following steps:

- immobilize the crankshaft using a pry bar or other tool by inserting it into the teeth of the clutch disc crown;

- loosen the bolt securing the roller or tensioner bracket, relieving tension from the belt;

- Unscrew the axial bolt completely and remove the roller;

- install a new roller and adjust the belt tension.

Replacing the generator belt tension roller should always end with checking its functionality and re-inspecting it. Please refer to your vehicle's owner's manual for detailed instructions on how to check that the alternator belt tension is correct.

It is important to remember that excessive tension leads to rapid wear of the roller bearing and, accordingly, to the need to replace it.

A modern motorist, for whom the garage is a “second home,” should know at least the most general concepts and ideas about what the structure of a vehicle is. At a minimum, this is necessary in order to identify all the symptoms of malfunctions that may arise at any moment, as a result of which they will need to be eliminated, which will also require certain knowledge and skills.

- 1. The generator belt roller is a spool, which is very expensive.

- 2. Replacing the tension roller of the generator belt is a matter of five minutes.

All this is due to the fact that even with a huge number of different workshops and service centers, in the middle of the road, when a breakdown occurs, the motorist will not find a single assistant, as a result of which he can only expect help from himself. If someone you know asks a car enthusiast why a generator belt tensioner pulley is needed, why even monitor the condition of this device, and claims that no one needs it, then he will be deeply mistaken and will be wrong. It's no secret that the main element of a vehicle is the engine. The functionality of this device is very diverse, so without its normalized state, the operation of the vehicle cannot be successful.

Thus, even the most minimal malfunction of an element that is “insignificant,” as the motorist thinks, can contribute to the breakdown of the entire system. If during periods of direct movement certain irritating factors arise, which take the form of whistling, tapping, creaking, or metallic ringing, then you must immediately turn your attention to the cause of this kind of breakdown. Otherwise, you can forget about your own comfortable movement, and you can also get a lot of material worries about restoring certain parts of the system.

We recommend: Diesel engine fuel supply system

The alternator belt is not unique, as it can also malfunction. Sometimes, when the belt whistles, a motorist resorts to replacing the generator, thinking that this will all end there. And how big a surprise the car enthusiast will be after this, noticing that nothing has changed. If all the rules for replacing a new belt and a new bearing are followed, the repair may not always be successful. This is because the belt tensioner may be damaged. This is precisely the detail that is of last interest to specialists from automotive services, since they believe that it is eternal. However, this device may also malfunction.

For normal and stable operation of the belt drive, the belt itself must be in ideal condition.

Its edges should not be stretched or peeling. In addition, a belt that has transverse or longitudinal breaks should not be allowed to be used. At the break of the belt itself there should be no cracks or any crumbled areas.

One of the most important factors that directly influence the quality of the generator is the degree of belt tension. So, everything will depend on the model of the internal combustion engine and the type of belt. To adjust this parameter in the automotive environment, there are certain devices through which the required tension can be achieved. Such a device could be a bracket, through which the generator itself will be pulled away from the engine in order to tension the belt. In addition, for normal operation of the electrical energy supply system, such systems must have a generator. The rotor of the generator device must be in continuous rotation, which can be ensured by means of a belt connection to the crankshaft of the car.

There are many reasons why the alternator belt squeaks and rubs. Thus, the belt itself could have become worn out, as a result of which its tension is no longer possible. In addition, the belt itself, even when initially installed by manufacturers, was invented from low-quality material. You should not think that normal work can be carried out even if the belt or pulley itself is exposed to various types of technical fluid, coolant, or antifreeze.

The generator belt roller is a spool, which is very expensive.

In addition to the fact that the internal combustion engine is the source of the force transmitted to the wheels, this device ensures the functioning of many different vehicle devices and its own subsystems.

The crankshaft is located at the front of the engine and necessarily has a single-row, double-row or three-row pulley. This device is connected directly to the generator, cooling system pump, power steering, gas distribution mechanism, through a soft belt drive.

All these devices perform their assigned functions, although most of them, like the engine itself, cannot but have a generator in their “helper arsenal”. Stable operation of this device as a source of energy can only be possible under one condition, which is sufficient belt tension. Most vehicles, both domestic and foreign, especially new models, have a special special-purpose device - an alternator belt roller. This part is capable of adjusting the degree of tension of the belt drive.

In the modern world, there are several modifications of this device. So, the roller may have an offset center, or the roller will be installed using an ordinary bolt directly on the movable bracket. You should always monitor the condition of this part, since it is because of it that you can get many problems in the future.

Replacing the tension roller of the generator belt is a matter of five minutes.

The design of the generator belt tension roller is quite simple. The main part of this device is the bearing. When a belt is replaced or loosened, diagnostics must be carried out at every opportunity to determine the general condition of the bearing. If rotation by hand is indicated by a quiet torque of the roller, then it is in good condition. If the life of the roller has already been exhausted, then you need to make a simple replacement, which can be done in your own garage.

In order to replace the tension roller device, you need to go a short way: immobilize the crankshaft using a pry bar or other similar tool, inserting it directly into the clutch disc teeth; you need to loosen the bolt by which the roller is attached to the tensioner bracket, apply stress relief to the belt; the axial bolt must be completely removed and the roller removed.

That's it, after all that has been done, you just need to install a new roller, also adjusting the degree of belt tension. Replacing a tension roller should always end with diagnostics and testing the functionality of the device.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.

Why is there a belt tensioner pulley in a car?

What is this and what is the video for?

Despite the fact that in any city the number of specialized service centers is constantly growing, such a breakdown can occur at the most inopportune time and place. Therefore, it is very important to know how to carry out such a procedure on your own.

The first thing we see when opening the hood of a Renault Logan is the engine. But those who think that it is needed only to keep the car moving are deeply mistaken. In fact, the motor is designed to perform a number of very important functions. In addition to the fact that the internal combustion engine (internal combustion engine) is a direct source of energy transmitted to the wheels, it also ensures the functioning of a number of systems, such as air conditioning, power steering and, of course, a generator.

All of the above devices are designed to perform their function, but most of them, including the engine, cannot do without the energy generated by the generator.

The generator charges the battery; if the tensioner pulley is faulty, the generator will not provide the required charge and you will stall.

Clear and stable operation of the generator is possible only when the tension of the belt drive is sufficient to supply energy to all consumers. Therefore, almost most cars, regardless of production, have a corresponding alternator belt pulley.

Tensioner device

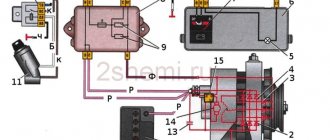

The tensioner design includes the following elements:

- belt;

- video clip;

- bracket;

- connecting bolts and nuts.

The roller is a bearing with a seating sleeve inside and a plastic coating on the outside. The belt moves along the roller. The roller is mounted on a bracket, which, in turn, is attached to the car engine using bolts and nuts.

We recommend: The most reliable and durable engines

There are two modifications of the tensioner:

- Eccentric. Includes bearing, plastic cover and bushing. The bushing has a through hole that is offset from the center. This hole is used to secure the roller to the car engine. To obtain the required belt tension, the eccentric is rotated and then the result is secured with a bolt.

- Bracket. In this modification, the roller is fixedly mounted on a bracket. The structure is attached to the power plant using bolts. To adjust the belt tension, the bracket is moved relative to the engine. This modification is more complicated than the eccentric one, but this does not make it any less reliable.

Some car factories install rollers with a spring bracket in their cars. In this design, the spring independently regulates the belt tension, that is, the unit is self-regulating.

Whatever device the belt tensioner has, the list of its main elements remains unchanged.

ATTENTION: The weak point of any tensioner is the bearing, which is constantly under load and wears out quickly. It is recommended to change this element every time the belt is replaced.

Main types, structure and principle of operation

The design of the tension mechanism consists of two parts:

- Video clip. It is made of plastic or metal with a smooth surface, which is placed on a 1- or 2-row ball bearing. When the power plant is operating, the roller rotates freely along with the belt. Such parts can be smooth or contain small collars that prevent them from moving. Depending on the configuration and length of the belt, one or two roller elements are installed in the belt drive.

- Tension mechanism. The component is responsible for optimal roller placement to maintain the required tension. The devices can be manual or automated.

Eccentric-type products are equipped with a bushing with an offset axis, which is located inside the roller. As the part rotates, the roller changes position and maintains the required tension.

In slider models, the roller rotates along the slider in a perpendicular direction, maintaining optimal tension. A screw is used to adjust the placement. However, due to the lack of compactness and reliability in comparison with eccentric models, such tensioners are installed quite rarely.

All manual mechanisms have several disadvantages:

- they need to be constantly adjusted using a dynamometer;

- When the belt is stretched and naturally worn, its tension may change.

The listed problems are eliminated by installing automatic tensioners. They are equipped with a special element that provides tightening of the belt drive with subsequent compensation of tension during wear of the part, temperature changes, changes in engine loads and other influences. In addition, automated products can act as shock absorbers that suppress belt vibrations, shocks, jolts and other mechanical vibrations.

There are 2 types of tensioners available for sale:

- spring (mechanical);

- oil (hydraulic).

The first include models with compression and torsion springs. In two versions, the intensity of the spring tension is determined at the factory, so it does not need to be adjusted when installed on the car.

Oil mechanisms have a complex design and high cost, but this is justified by their efficiency and operational advantages. The system not only maintains belt tension, but also eliminates tension variations over a wide range. The tensioner is based on a hydraulic cylinder, which is installed using two methods:

- Installation using a bracket and a roller - in this embodiment, the cylinder rod rests against a support bracket or against a stop on the engine block.

- Installation on the engine compartment - the method involves mounting the cylinder rod on a movable roller bracket.

Manufacturers of automated tensioners (both mechanical and hydraulic) sell them in a compressed state. The rod mechanism is held in place by a pin, which is removed after mounting the device on the power plant. As a result, the roller moves to the desired position, maintaining tension without prior adjustment.

Why do you need a generator and how to check the tension of the generator belt

Checking the tension of the generator belt

On some small commercial vehicles (Fiat Doblo), the drive belt is tensioned by deflecting the alternator housing.

The generator is the source of electrical energy in the car. When the engine starts, the generator rotor rotates at a certain angular speed, which is communicated to it through the drive belt. A magnetic field is created in the stator windings, which leads to the generation of electric current. But the current has a variable value, and to power all devices on the on-board electrical network, the current must be constant. In such cases, a diode bridge is installed on the generator, which rectifies the current. On some small commercial vehicles (Fiat Doblo), the drive belt is tensioned by deflecting the alternator housing, i.e. The engine design does not provide for the installation of a tension roller. However, the most common is to tension the drive belt with a special roller, and there can be several of them: tension and bypass. Some rollers are self-tensioning, i.e. It is enough to install them on the engines and remove the bracket that secures the roller body and the roller itself, and it will create the necessary pressure on the belt. In other cases, when tensioning the roller, it is necessary to align the marks to tighten the belt. The tension of the generator belt is checked during maintenance. For diagnostics, a special device is used that will show in kgF (kilogram force) the pressure that must be applied to deflect the belt. But the easiest way is to use two 10 - 20 centimeter rulers: you need to place one ruler horizontally on the belt, and move the second in a vertical plane. The normal tension of the generator belt will be no more than 1.4 - 1.6 mm.

Generator drive device

The main condition for the correct functioning of the generator is the correct transmission of rotation from the power plant. To generate the required amount of electricity, the element must rotate at high speed.

The alternator drive belt must be tensioned for proper transmission. If the belt sag, it will begin to slip on the pulleys. If the belt is overtightened, there is a risk of premature wear of the bearings, working surfaces of the pulley and belt.

To avoid these troubles, belt tension adjustment was included in the design.

In modern cars the number of attachments is large. This equipment is also driven by the crankshaft pulley, including the power steering pump and air conditioning compressor.

The drive of these two units and the generator is carried out using a single belt. Because of this, it is impossible to adjust the tension of the drive element using a generator. Such cars have a complex belt position configuration. Belt-driven equipment is located at different levels.

How to change the alternator belt tensioner pulley? To do this, you need to understand its structure. The generator belt tensioner roller is a bearing with a plastic lining on its outer race. The pad has a working surface along which the belt moves. There is a landing sleeve inside the roller. There are two types of rollers:

- Eccentric . The design of this video is quite simple. It contains only a bearing, a plastic lining and a bushing. A through hole passes through the bushing, offset away from the center of the roller. The roller is put on a pin through the hole, which is installed on the engine. To tighten, the roller must be rotated relative to the bolt.

- Roller with bracket . In this design, the roller is fixedly mounted on a bracket. The structure is attached to the power plant using bolts. Moving the bracket relative to the engine adjusts the tension. Manufacturers sometimes use rollers with a spring bracket. The spring allows you to independently adjust the tension.

The bearing is the main weak point of the roller. This part is forced to constantly experience loads. Wear of a part sometimes even ends in its complete breakdown.

It is recommended to change the bearing every time the belt is replaced.

Replacing the roller yourself

In contrast to a V-belt timing drive, replacing a car's alternator belt roller is much simpler. Therefore, if you follow the recommendations below, the car owner will be able to perform the operations on his own, after first making sure that the cause of the malfunction really lies in the wear of this consumable.

Diagnostics

Malfunctions of the tensioner installed on the generator belt drive are diagnosed in 90% of cases by a characteristic sound resembling a whistle. However, the tension may weaken, not only from the wear-out of the roller, but also for other reasons:

- misalignment - in the absence of alignment of the shafts and pulleys of the belt drive, accordingly, the sound arises due to poor contact of the belt in the cross section, one edge wears out intensively, the other remains intact

- ingress of lubricant - in the absence of tightness, oil can get onto the belt, sharply reducing friction, leading to slipping and destruction of the rubber, it is recommended to remove the consumable part, wipe it or replace it entirely, eliminating the cause of the oil leak

- hard belt - usually whistles when starting, then heats up, the sound disappears, this is caused by an increase in loads on the pulleys

- bearing wear - the whistle is slightly different in tone, the cause is the wear of the race, the bearing is removed for replacement

- belt sagging - no need to change anything, tensioner needs to be adjusted

- lack of battery recharging - determined by the instruments on the panel

In other cases, the whistling can be eliminated by removing the roller and replacing it with a new consumable. The shine on the working surface of the belt indicates its frequent slipping, the cord peels off from the oil, but cracks on it under normal belt tension are much more difficult to notice.

Dismantling

Before changing the alternator belt tensioner roller, it is necessary to loosen the V-belt drive:

- the tension roller adjusting bolt is loosened until the belt can be removed

- together with it, 2–3 nuts of the tension bar are loosened (usually 10 and 13)

Attention: Depending on the layout of components/assemblies under the hood of a particular car model/brand, in order to provide access to the tensioner and roller, accordingly, some components and parts will have to be dismantled.

Rice. 7 Removing the roller

For example, on a ZAZ SENS you need to remove the belt that drives the air conditioning compressor shaft. You won’t have to remove anything for Chevy/Niva and Lada Granta.

Alternator belt roller for Renault Logan

The tensioner roller is indicated by a line in the figure.

- On Renault Logan cars, the tension roller of the alternator belt is installed on cars that are equipped with power steering and air conditioning, or one power steering.

- On models that do not have such options, the alternator belt is tensioned using a bolt on a special strip.

Let's consider the options for replacing the roller separately in each case.

Replacing the tension roller of the alternator of a Renault Logan I generation car, equipped with power steering and air conditioning

The roller is marked with the number 2

The tension roller is shown in the diagram as number 2 .

This is what the old video looks like

- To replace it, you need to remove the right wheel and the protective shield of the engine compartment.

- Next, using a key set to “13,” we turn the roller mounting bolt clockwise (bypassing the force of the tension spring), at the same time, using a metal rod with a diameter of 5–6 mm, we fix the roller bracket by inserting it into a special hole. This way you can loosen the drive belt itself for further removal of the roller.

- In order to unscrew the roller from the engine housing, it is necessary to unscrew the two bolts securing the housing of this tension device, which is assembled with the roller itself.

The process of filming the video in the photo

Installation should be done in the same way in the reverse order, and special attention should be paid to the high-quality fixation of the bracket itself.

We recommend: Throttle training - the essence and subtleties of the operation

Replacing the tension roller of the alternator of a Renault Logan I generation car, equipped with power steering and without air conditioning

The tensioner pulley is numbered 2 in the diagram.

In order to remove or adjust the generator belt through the adjusting roller ( number 2 ), it is necessary to loosen the bolts securing the roller 4 and rotate the adjustment bolt 3 clockwise. If the roller itself needs to be replaced, then dismantling is carried out by removing the bolts securing the roller from the engine housing.

Filmed video

After completing all operations, the assembly of the structure occurs in the reverse order.

After replacing such “consumables”, you need to start the engine and make sure there is no extraneous noise at idle or whistling from under the alternator belt. If nothing of the kind is installed, then the replacement of the tension roller can be considered complete.

When carrying out repair work related to belts, pay attention to the condition of the timing belt, replace it if necessary (read more about replacing the timing belt on a Renault Logan).

Troubleshooting

The following signs indicate a malfunction or wear of the alternator belt tensioner:

- the headlights shine dimly;

- The indicator lights on the dashboard do not seem as bright as usual;

- interior heating works intermittently;

- the car siren has become duller and lower;

- the operating intervals of windshield wipers and turn signals have increased;

- There are no battery charging indicators;

- The alternator belt tensioner assembly makes a whistling sound, hum or squeak;

- When the engine is turned on, the roller or belt vibrates.

If at least one of the above symptoms is present, we diagnose the condition of the alternator belt tensioner. We perform all operations in a certain sequence.

Step 1. Open the hood of the car and conduct a visual inspection of the unit. If cracks, traces of rust, or misalignment of the tensioner block or tensioner arm are detected, we replace, adjust, or adjust the worn parts.

Step 2. Start the engine and observe the operation of the unit. We pay attention to vibration, noise (creaking, crackling, whistling), resistance during rotation, beating of the lever during operation and other deviations from the norm. If extraneous sounds are heard from the unit, we try to understand which part is causing them.

Step 3. Check the serviceability of the video. To do this, remember the position of the generator belt and remove it from the unit, having first loosened the adjusting nut. Next, we proceed to inspect the video. Its surface should be smooth, without deep nicks and other damage that contribute to belt wear. We rotate the roller and make sure that the rotation is free and that the roller does not jam. If the roller is in order, we install it in its original place.

Step 4. Check the integrity of the belt. There should be no peeling or cracks on its surface, in the presence of which the belt must be replaced. We pay special attention to the uniform wear of the belt. If there is wear on one side, inspect the bracket or stud for attaching the roller. These parts may be bent or askew. If the misalignment is not corrected, the new belt will not last long.

Step 5. Check the belt tension. To do this, with the car engine stopped, we grab the belt and try to turn it 90 degrees clockwise. If the belt rotation angle deviates from 90 degrees, it needs to be adjusted.

ATTENTION! Experts recommend checking the tension of the generator drive belt at least once a week, and constantly having a new belt in your emergency supply.

How to understand that the drive belt tension roller needs to be replaced

If you notice one of the problems listed above in your car, you need to check how the tensioner of the engine drive system functions. At the same time, diagnostics is also necessary for other nodes. The functionality check is carried out in stages:

- External inspection of the drive belt and the mechanisms it drives It is necessary to start the engine to check whether there is any runout of the belt, tension roller or pulley, and then consider replacement.

We recommend

“Antifreeze leaves the expansion tank: causes and diagnostics” Read more

- Checking the elasticity of the generator belt

Stop the running engine. Then, at the longest gap between the pulleys, try to turn the belt to the right. If you can move it 90°, then the tension is normal. If the scroll angle is greater or less, the tension must be adjusted. - Dismantling and checking the functionality of the belt

At the same time, you need to inspect the pulleys and rollers, in particular, for the presence of play. The belt is easy to remove. Lightly unscrew the tensioner nut to pull it off the pulleys. But first you should remember this position, since later (after replacement) the belt must be put on the same place.Take your phone and just take a photo of your gear. Check the removed drive belt for cracks and delaminations. It should wear evenly. If you notice any defect, do not skimp on replacing the drive.

One-sided abrasion indicates that the roller mounting pin or bracket is bent and causing misalignment, which must be urgently corrected. Otherwise, your belt will quickly become unusable.

- Checking the play (free play) on the pulleys

Rotate the roller to make sure there is no obstruction in movement. Any binding indicates a worn bearing, which means you will need to replace the generator drive belt roller. Don't forget to inspect the contact surface of the plastic pad, which should be smooth. If you see grooves and irregularities, the tensioner should be replaced.After installing the new roller, the hum and squeak should disappear. Otherwise, the cause of the malfunction is in other places. And the drive of these elements is carried out due to the elasticity of the belt.

Malfunctions of the electrical equipment of the car

The main reason for the decrease in generator performance is the weakening of the belt tension. But before you approve anything, it is necessary to diagnose the electrical equipment of the car. Signs and causes of malfunctions of on-board network devices:

The main reason for the decrease in generator performance is the weakening of the belt tension.

- headlights flicker when the engine is running;

- The alternator belt whistles when starting on a cold engine;

- when using electrical appliances, fuel consumption increases significantly;

- extraneous noise in the drive belt area;

- The generator belt tensioner roller whistles;

- The battery is often ;

- mechanical damage to the belt and roller.

The worst thing that can happen to the belt is a break, and the roller can jam. In these cases, the generator will not work, and its functions will be taken over by the battery. But the battery will not last long because it has limited capacity. The main purpose of the battery is to supply the starter with starting current for reliable starting of the engine. The generator, among other things, performs the function of recharging the battery.

Signs of a faulty alternator belt tension roller

First, make sure that the alternator belt tensioner pulley needs to be replaced. Signs of its malfunction are listed below:

- the generator does not fully charge the on-board network or it does not receive electricity at all;

- from the side where the belt is located, a sound similar to squeaking is heard;

- a hum is heard;

- the roller or belt vibrates a lot when the power plant is running;

- there is play in the video;

- The belt is worn on one side.

This is interesting: Causes of persistent chemical deposits in passenger car engines

Some of these symptoms may indicate a problem with the components that drive the roller. A hum and squeaking noise may indicate wear on the bearings of the power steering pump, air conditioner or compressor. The malfunction may lie in the generator itself.

Signs of failure

There are several signs of problems in the operation of this element:

- the generator does not fully charge, or no electricity is supplied to the on-board network at all;

- squeak from the side of the belt;

- increased hum;

- strong vibration of the roller or belt when the power plant is running;

- play in the roller;

- belt wear on one side;

It is worth noting that some symptoms are also inherent in malfunctions with the elements that the roller operates. For example, a hum or squeak can also be the cause of wear on the bearings of the power steering pump, air conditioning compressor and the same generator.

Video: Repairing the generator belt tensioner pulley

Do-it-yourself replacement of the Hyundai Solaris alternator belt tensioner roller

In Hyundai Solaris, the tension roller can be called a sore spot. Often they even replace it during the warranty period. If your warranty has expired or you are not serviced by an authorized dealer, you can replace the roller yourself. Typically, the tensioner is replaced simultaneously with the replacement of the accessory belt.

To replace the tensioner you need:

- Remove the mudguard of the engine compartment on the right.

- Using a screwdriver, press the tensioner to loosen the belt tension.

- Remove the alternator belt.

- Unscrew the tensioner mounting bolt.

- Pull out the pain and remove the tensioner assembly.

- Install a new tensioner, belt and assemble the parts in reverse order.

Usually there are no difficulties when replacing the tensioner. When installing, make sure that the mark on it fits into the special opening on the cylinder head. If you doubt your own abilities, it is better to consult a specialist.

After installation, check that the belt runs smoothly and without any extraneous sounds. If installed correctly, the Solaris generator belt tensioner roller will last until the next belt replacement.

How to replace the bypass drive belt roller

This operation is carried out in strict compliance with the manufacturer’s instructions, developed specifically for car repair and maintenance. Taking into account the drive structure and the location of the belt, replacement can be carried out without removing it or with dismantling it.

One way or another, the procedure for installing spring tensioners is the same. They are placed in a certain place and the pin is removed, releasing the spring, which tensions the transmission belt. If the device is installed incorrectly, it will be difficult to install it again.

Replacing a generator drive belt roller or other component is quite easy to do yourself. It does not require the use of special tools. How to do it:

- Remove the terminals from the battery to disconnect power from the vehicle.

- Using a pry bar or auxiliary devices, block the crankshaft from accidental rotation.

- Unscrew the bolt that changes the tension force to loosen and remove the drive belt.

- Remove the tension roller (if there is a bracket, unscrew its fasteners).

- Replace damaged parts and reassemble the mechanisms in reverse order.

Correctly selected and installed parts ensure smooth operation of the drive and the engine as a whole.

Check the tension of the new belt after replacement. If it is tightened too much, it will wear out faster because the bearing will be constantly overloaded.

The correct tension can be checked manually or using a specialized device for this. With the manual method, a precisely installed drive belt will easily rotate through an angle of 90° if a lateral force is applied.

Along with cars that have several belts (for alternator, power steering, air conditioning, etc.), there are vehicles with one drive. It is adjusted by an automatic tensioner. In this case, the tension of the belt affects the charging of the generator, the operation of the cooling system and the power steering. The main part of the tension roller is a spring that creates the necessary tension.

If the car needs to replace the belt transmission element, then it is better to completely replace the automatic tensioner (even if the bearing is working normally), since this mechanism cannot be repaired in parts.