CV joints are the main instigators of knocking noises during rotation

Often problems are solved by replacing CV joints. This is a rotary mechanism in the external version and an object of independent transmission of torque in the internal version. If before the mystical knocking sound appeared when turning, you did not hear crunching sounds, then the internal CV joint may be to blame. The outer one fails more often, but before failure it begins to crunch when turning. You can check the part as follows:

- put the car in the pit, turn off the speed and turn on the handbrake for easy access to the axle shafts and other suspension elements in the front of the car;

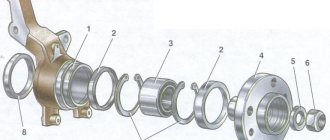

- check for play on the axle shafts by loosening them from top to bottom or in different directions, then check the play by pushing the axle shaft inside the CV joint and back;

- if there is play, the parts have fallen apart, they need to be replaced, you should buy only high-quality spare parts to carry out the necessary repair processes;

- Before replacing, do not forget to drain the oil from the gearbox, since otherwise it will simply flow out through the holes that appear at the site where the CV joints are installed.

The process of replacing internal CV joints is quite complicated. Interestingly, the main reason for parts failure is a torn boot. A part that costs a hundred rubles damages an expensive mechanism that is very difficult to replace. So it is worth monitoring the condition of the anthers and always changing them if necessary.

Ball joint - knocking in the suspension of different characters

There is a part in the car suspension that is difficult to check. If it knocks, it happens precisely on small and unnoticeable irregularities. The ball loses its lubricant and begins to move very difficultly inside the seat. This causes sounds like creaking, light knocking, and annoying rattling. An element fails for the following reasons:

- just natural wear of the part, which occurs every 100,000 kilometers; during operation, the mechanism wears out, lubricant comes out, and efficiency decreases;

- the support begins to knock quite unexpectedly, the intensity of the sounds quickly increases, so it is better to promptly replace the element;

- when installing a low-quality support, a not very pleasant process occurs - after a few thousand kilometers, extraneous sounds appear that are unpleasant to listen to;

- Also, a torn boot is one of the main causes of problems in this part of the car, so you should constantly look at the rubber bands and their integrity.

The ball joint is very difficult to diagnose. To check it, it must be removed, which cannot be done without the help of a professional service. That is why they often do not sin on it when going through other suspension parts. It may well happen that you change half of the suspension until you get to the knock directly in the ball joint.

Causes of extraneous noise and knocking

There can be plenty of reasons for extraneous noise and knocking in the front suspension. When parts wear out, the brakes, steering system, and engine can rattle. However, the greatest amount of noise in the presence of defects occurs in the suspension and shock-absorbing units; read more about the Renault Logan front suspension design here.

In order to carry out an independent inspection, and, if necessary, repairs, you will need a lift or inspection hole.

Support stand

For comparison: old and new support strut on Logan

Before you begin inspecting the suspension under the car, first assess the condition of the front strut supports. To do this, you need to open the hood and evaluate the gap on the spring stop cup.

Check the gaps!

If the gap exceeds 1 cm or it differs relative to the opposite side, this indicates that the supports have sagged and they do not absorb impacts on small bumps, therefore, they need to be replaced.

Shock absorber struts

The presence of a dull knock in parts of the front suspension may indicate defects in one of the shock absorber struts. The easiest way to diagnose is to alternately rock the car on the left and right sides. If there are working shock absorbers, the car will smoothly return to its original position, already on the first or second free play.

The presence of smudges and unsatisfactory condition of the bumpers will also indicate that the rack should be replaced.

Read more about diagnosing and replacing front struts on Renault Logan here.

Anti-roll bar link

This chassis element is checked when the vehicle is under load. By rocking the car, you should pay attention to the movement of the cup relative to the lever itself. If this element malfunctions, it will jump and make a characteristic knock, which in turn, undoubtedly, is observed when driving on an uneven road.

Inspection and replacement of the stabilizer bar link

More details in the material: changing the stabilizer struts on a Renault Logan with your own hands.

The same goes for the anti-roll bar bushings. When they wear out, play and free movement will be felt in the places of contact with the rod itself. Diagnostics and replacement of stabilizer bushings can be carried out both on the ground and with the car suspended.

We recommend: The main causes of problematic starting of a cold car engine

Silent blocks

The arrow marks the silent block

After the car has been raised, you should check the silent blocks in the suspension arms. In order to determine the degree of their wear, you will need a mount, with the help of which, by moving the lever on the subframe in the longitudinal and transverse directions, you can determine their play, as well as identify rubber defects.

On Renault Logan, the silent blocks are attached to the front suspension arm, so their replacement should be carried out on a removed element.

Spherical bearing

Diagnostics of a ball joint is diagnosed in the same way as silent blocks. By turning and pushing movements (left - right) you should influence the front suspension lever, and if the ball joint is faulty (there is play), moving it will not be difficult.

Ball boot diagnostics

The support on the Renault Logan is pressed into the front suspension arm. Therefore, before dismantling it, the lever must first be removed, and the replacement itself must be carried out using a press. Read more in the material: replacing and diagnosing a ball joint on a Renault Logan.

If the ball joint is sentenced to replacement, then it is important to know which ball joints are better!

Struts and strut supports are a problem for every car

Even high-quality and reliable racks begin to struggle with unevenness and knock after prolonged use. For a Chinese spare part, a long service life of 1000 kilometers is considered, for an original Japanese or European one - 15-20 thousand. Struts and upper supports regularly fail on cars in Russia, and the reasons for this can be very different:

- the strut itself rarely fails completely; when the car is rocking, creaking and extraneous sounds will be heard, and the knock will be heard throughout the entire suspension at once;

- the support in most cases fails at the moment when the support bearing breaks, this happens in the event of a sudden collision with large uneven roads;

- Perhaps a simple tightening of the support or shock absorber fastening at the top point will help you; you need to check all fastening elements;

- If the struts break down, they may leak, which will be visible on the body, but this is not a prerequisite, but simply a recommendation for additional diagnostics of the suspension element.

It is better to install only high-quality parts of the chassis. We are talking about original or European spare parts. Many motorists use Japanese KYB parts and buy quite adequate Monroe struts. The supports must be installed using original ones, despite their high cost. This is the only chance to get the necessary aspects of operation.

The steering rack is a quiet, separate element with sophisticated diagnostics

It often happens that after reassembling the entire chassis, it is time to check the steering rack. By moving the steering wheel left and right, you will hear small knocks if the rack has already begun to wear out. But this does not mean at all that it knocks during operation. It is difficult to give general recommendations here; there are different recommendations for owners of different cars:

- It’s worth visiting specialized forums and reading information about how and when the steering rack fails, how you can check and fix it;

- tightening the steering rack is a solution for a few days; soon it will start knocking again if a problem is identified with this particular element of the car;

- the knock of the rack is often a distinct feedback on the steering wheel, as well as on the body in the area where the control pedals are attached, so diagnosis will not be difficult;

- Sometimes steering tips or rods knock, which is more difficult to check, but you can perform a full diagnosis in a pit without any problems or inaccuracies.

The steering system likes to knock in domestic cars, as well as in cars older than 10 years. Changing the steering rack is very difficult due to the high cost of spare parts and the rather inconvenient location in many cars. Therefore, they prefer to perform this process on a service. Professionals will complete all tasks quite simply and quickly.

Silent blocks in the front of the car - replacement check

A very important element of the front suspension, which can knock in the most unusual way, is a set of silent blocks. The most common knocking sounds are the rear silent blocks of the front suspension arms, as well as the support silent blocks of the stabilizer, which are attached to the body. The whole problem is solved by replacement, there is no point in diagnosing for a long time - it is better to change the part. Failure occurs for the following reasons:

- the rubber simply breaks due to increased loads, it does not withstand too much pressure and is deformed under the influence of the connections of the suspension arms;

- The silent block stops turning freely in the right place, there is no flexibility in the suspension, and the levers knock due to the lack of the required maneuver;

- the rubber has worn through, worn out and decreased in size, so metallic sounds are heard from the chassis, which are difficult to diagnose;

- It is necessary to pay attention to the fastenings of silent blocks; often replacing them turns out to be difficult due to preliminary unskilled work with suspension parts.

You can check while driving whether the rear silent blocks of the front control arms are knocking. You need to place your foot directly on the floor and listen to whether there is a knock on your foot. The same procedure should be done on the passenger seat. The stabilizer support bushings are checked by placing your foot or hand on the part of the body behind the pedals. However, if you have suspicions, you can simply change this element. We invite you to watch a short video with self-diagnosis of the Hyundai Solaris suspension:

Engine support cushions

The pillows contain rubber elements that wear out over time. Because of this, the car rattles when driving.

You need to open the hood and start the engine. Strong vibration indicates that the parts have become unusable. If the engine shakes or tilts more when you press the gas, it's time to change the elements.

You can check the integrity of the pillows yourself without visually. You need to try to shake the power unit. If the action can be performed without effort, it’s time to change the pillows.

You should not ignore such a breakdown; due to the force of vibration, various components are destroyed. When the part becomes unusable, the motor breaks off its mounts, and serious repairs will be required.

You can change the pillows yourself. Without work experience, you should contact the experts.

Let's sum it up

It is worth using various methods to test equipment before replacing. Otherwise, because of one knock, you can change half of the suspension without eliminating the cause of the problem. Therefore, you should always approach diagnostics from different angles and use the services of testing suspension parts at several service stations. You can change parts only if you are sure that certain mechanisms are faulty. You should approach the issue of repair with full understanding so as not to spend too much money on this process. Many novice drivers simply buy every part that they are guilty of, and as a result, repairs are very expensive.

There are certain difficulties in diagnosing the chassis of a modern car. It is not at all clear which element may be causing the knocking. There are a number of possible options, they are all interconnected, and even analysis does not answer the question. Therefore, it is very difficult to use the full picture of the breakdown to purchase the spare parts necessary for repair. Sometimes you have to change parts just at random, not getting the result on the first try. There are various repair options available, but to do so you need to pinpoint the problem. How do you usually diagnose and repair the chassis of your car?

Stabilizer bushings

It is difficult to determine the breakdown of elements by sound. In order not to change the part, you need to check the bushing by hand. This can be done by a mechanic at a service station.

The malfunction can easily be confused with failed silent blocks. The difference is that if the bushings are installed on a subframe, the driver will feel vibration in his legs while driving.

Attention! It is impossible to check and replace the bushings on a lift; you need an inspection hole or platform so that the load is applied to the wheels.

If the parts are faulty, vibration will occur on any bumps.