The VAZ 2190 Lada Granta passenger car produced by the Togliatti automobile plant was produced for several years. Beautiful appearance, good build quality, and the presence of several modifications were liked by a large number of people in many regions of the Russian Federation and CIS countries. On the power units with which this machine is equipped, the Grant timing belt requires special attention. Drivers and potential buyers of this car on the secondary market will be interested in learning about the correct operation of the engine, maintenance and replacement of the timing belt.

Characteristics of Lada Granta timing belt

The Lada Granta gas distribution mechanism is driven by a belt. This type of device has been familiar to car enthusiasts for a long time. After all, the timing belt design migrated from the VAZ 2108 engine, which became the basis for all subsequent modifications of VAZ power plants. The Grant is equipped with two types of engines: an 8-valve engine and a 16-valve engine. The gas distribution system of the 16-valve power unit has a complex structure and increased dimensions compared to the 8-valve one. Accordingly, replacing the Granta timing belt becomes more complicated.

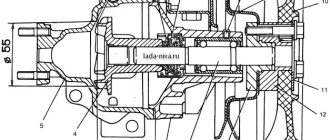

The main feature of the 16-valve device is the presence of two camshafts operating synchronously, in parallel with the crankshaft. The structure is located in the cylinder head. All three shafts are synchronized via a toothed belt. The main disadvantage of a timing belt drive is the unreliability of the belt itself. When it breaks or jumps, the valves meet the pistons and bend. The structure of the 16-valve timing belt is clearly shown in the photo.

16 valve unit

- Installation mark on the drive cover.

- Lid.

- Intake camshaft pulley.

- Phase disk (sensor).

- TDC mark on the camshaft.

- Exhaust camshaft pulley.

- Support roller.

- Tensioner roller.

- Drive belt.

- Pump pulley (coolant pump).

- Installation mark on the oil pump.

- Crankshaft alignment mark.

- Crankshaft pulley.

You can change the timing belt kit yourself. The main thing is to know about the presence and correct placement of installation marks. By the way, most foreign cars do not have such marks, so in this case VAZ cars have the advantage.

The eight-valve timing drive of the Lada Granta, compared to previous modifications of the car, looks simpler. The scheme is simple, because there is no idler roller and there is only one camshaft. The 8-valve timing device can be seen clearly in the photo.

Replacing the timing belt on a 16-valve Granta engine

Access to the gas distribution device drive is covered with a plastic casing. To remove the cover, you need to unscrew five screws with a 5mm hex key.

Pay special attention to the location of these screws. In the photo, number 1 shows the fastening screws of the top cover, and number 2 shows the fastening screws of the bottom cover.

After unscrewing the five screws, the top cover must be lifted and removed from the engine.

If the car has a manual transmission, you need to engage fifth gear, lift the right front wheel and turn it clockwise. At the same time, it is necessary to inspect the belt for cracks, abrasions, delamination, etc. If the car is equipped with an automatic transmission, you need to remove the right front wheel and the boot (protective shield) on the right. Using a 17mm head, rotate the bolt securing the drive pulley for additional equipment (air conditioning, generator) and inspect the belt. If various defects and damage to the belt are diagnosed, it must be urgently replaced. Replacement will also be required if oil leaks, a malfunction of the water pump or tensioner roller are detected.

On a 16-valve engine, a broken belt drive will lead to a discrepancy in the angular position of the crankshaft and camshafts. As a result, the piston group will come into contact with the valves. As a result, repair work will be required.

About engines

When designing the VAZ 2190 began, the previous model of this plant, Lada Kalina, was taken as a basis. Granta went on sale at the end of 2011. The buyer is offered to choose a power unit from five different engines, which can be:

It should be noted that the working volume of all engines installed on the Lada Granta is 1600 cm 3.

- The first engine from the VAZ 11183-50 is a modified VAZ 2111 unit. The designers managed to improve not only environmental performance, but also the reliability of the power unit. The timing drive has 8 valves that require periodic adjustment. Experts and car owners note the high noise level of the engine. A broken timing belt does not cause damage to valves or other parts of the mechanism.

- The second engine from the VAZ 11186 is an improved VAZ 2114 engine. Eight valves in the timing belt, increased engine power, improved environmental friendliness, fuel efficiency, and reduced operating noise. When it breaks, the valve bends, so replacing the timing belt on a Lada Granta must be done in a timely manner.

There are also engines with 16 valves in the cylinder head. One of the best among them is considered to be VAZ 21126 , this is a modernization of the 21124 series engine. All the positive aspects of this engine are spoiled by damage to the valve mechanism when the timing belt breaks. The VAZ 21127 power unit is a modernization of the 21126, which has become more powerful, but the valve bends when the timing belt breaks. The VAZ 21126-77 series of engines is designed for Grant Sport variants; the valves on them are also damaged when the belt breaks.

Factory regulations for timing of timing belt replacement

Each vehicle manufacturer specifies the timing of maintenance and other routine maintenance. According to this document, replacing the timing belt on a Lada Granta car should be done when the car has driven no more than 75 thousand km. In fact, this figure does not always correspond to reality; there are a number of reasons for this. The service life of a timing belt will depend on:

- The quality of the product used.

- Vehicle operating conditions.

- Technical condition of the engine.

- "Age" of the timing belt.

Much attention is paid to the manufacturing quality of rubber products, but the quality of parts from different manufacturers varies greatly. The main supplier for VAZ is the RTI plant, which is located in Balakovo. In addition to it, engines can be equipped with products from other companies such as Gates, ContiTech, Trialli, Bosch, and some others. You should carefully consider the product you are purchasing, since you can buy a fake under the guise of products from well-known manufacturers.

The operating conditions of the vehicle, especially its engine, also affect the service life of the timing drive. In 16 valve modifications, the load on the belt teeth increases, so it requires more attention. Fuel and technical fluids are not allowed to enter the operating area of the timing mechanism drive. They soften the body of rubber products, make the material pliable, and the teeth are easily cut off. At the slightest manifestation of leaks in the operating area of the timing drive, they must be eliminated immediately.

The teeth of the crankshaft gears and camshafts gradually wear out, and the height of the teeth decreases. This means that the contact area with the belt becomes smaller, making it easier to tear off the toothed belt comb. The coolant pump can also become a source of trouble for the timing drive. Sometimes it jams, and since the pump is rotated by a toothed belt, its teeth are cut off.

With a relatively small annual mileage of the car, you should also carefully monitor the condition of the timing mechanism parts. The belt ages even if the engine is not running, so it is inspected at every maintenance. If even small cracks are noticed, the delamination changes. The optimal time to replace the timing belt in the timing mechanism drive will be a mileage of 50–60 thousand km.

Recommendations from Lada Granta owners

You can find a lot of material on this car model on the Internet. Lada Granta owners (call themselves grant owners) talk about their cars and give recommendations on how to properly recommend a car. Drivers of 16 valve Grant recommend not to wait until the mileage is 50–60 thousand km, but to change the drive earlier. On the Grant 8 valve, if the drive in the “83” engine breaks, no damage to the valves occurs; for other modifications of the power unit, this can result in an expensive engine overhaul. You should not skimp on replacing the tension roller or coolant pump; they are the ones that most often damage the belt teeth.

Replacement frequency

The manufacturer's technical documentation states that the timing belt on the Lada Granta must be replaced every 60 thousand kilometers.

But here it is worth noting that this is a limit value and it is better to replace it before reaching such a mileage, approximately 50 thousand km, but there are cases when the drive requires replacement at 40, or even 30 thousand km, it all depends on the quality of the belt and its working conditions.

In any case, it is better to periodically check the condition of the drive (recommended every 15 thousand km) and if signs of wear are detected, replace it immediately.

If this is not done, then it may break, which is fraught with serious consequences - the engine pistons will collide with open valves, leading to their damage and subsequent expensive repairs.

Why does a belt suddenly break?

In some cases, even a new part can suddenly break, causing a lot of inconvenience to the owner of the vehicle. Most often, the teeth are worn out due to the fact that the Grant timing belt was installed incorrectly. In this case, it runs crookedly on the pulleys and rollers and its teeth “eat” the metal elements of the pulleys.

Other causes of premature wear may include:

- Poor part quality. In this case, savings can play a cruel joke on the driver, so you need to make a purchase in trusted stores

- Pump malfunction. This is one of the most common causes of breakdown. The pump rollers break over time, forming a gap and displacing the axis. As a result, its teeth quickly wear out and lead to breakage.

- Tension roller malfunction. The same thing can happen with a roller as with a butt. A bearing failure creates play and displaces the tension axis.

- Oil or antifreeze leak. When technical fluids get on the belt, they destroy the rubber from which it is made and greatly affect the strength of the part.

- Wear of pulley teeth. If the camshaft or crankshaft gears are severely damaged, integrity will be immediately affected. In this case, the teeth will have delamination on their surface.

In addition to all of the above, the fact that the timing belt on the Lada Granta 8 suddenly breaks can be caused by a trivial reason for its untimely replacement.

If the frequency of replacing the Lada Granta timing belt is not correct, then the driver should count not only on purchasing a new one, but also possibly on a complete engine repair. The cause of the rupture can be diagnosed according to the following scheme:

Inspection and signs of wear

The manufacturer recommends carrying out a visual inspection of the belt every 20 thousand kilometers, despite the fact that the declared service life of the original part is 75 thousand kilometers.

The belt is inspected on a cold engine, for which the cover of the gas distribution mechanism is first dismantled. If the glass washer fluid reservoir gets in the way during inspection, it is also better to remove it.

Both the tank and the lid are secured with simple bolts, so there will be no problems with dismantling.

To accurately determine the condition of the belt, you must also remove the right front wheel and the splash guard.

Using the 17 head, the crankshaft rotates to the right; you need to hold on to the powerful bolt that secures the drive pulley of the auxiliary elements.

Signs indicating the need for urgent replacement are as follows:

- material delamination;

- formation of longitudinal and transverse ruptures, cracks, convex areas;

- fractures in the area of the teeth;

- traces of soot and melting of the material on the back side of the belt;

- tousled material in the end area.

Please note that the reason for replacement is the presence of even one sign.

We would like to separately mention the presence of oil stains on the part. Even if it looks normal, it is better to change it, since oil destroys the material.

What happens if you set the tags incorrectly?

The consequences of improperly performed work can be both minor and very noticeable.

It is for this reason that it is important to approach all work responsibly. If you don’t have the proper attitude or self-confidence, entrust the work to a professional auto mechanic

Depending on the brand of the car, the following troubles may arise during the operation of the car:

- Misaligned phases often cause valve burnout

- Valve bends on some VAZ family cars

- Possible deformation of the cylinder head, failure of the guide bushings, and the formation of cracks inside the elements

- Remaining oil on spark plugs

The above consequences of incorrect label installation are observed in most cases. But, for example, on an 8-valve VAZ-2114 engine, the valves do not bend or bend even in the most severe cases. But the 16-valve power unit of the “fourteenth” does not have such advantages, so a major overhaul of the engine may be required.

On the question of motors

Grants are equipped with five power plants. Two of them are equipped with 8 valves, 3 - 16. We will consider 16-valve engines as the most technologically advanced, powerful and in demand.

The leader in popularity is the VAZ 21126 modification, which is a redesigned and improved version of the unit under the symbol 21124.

Other 16-valve engines have indexes 21127 and 21126-77 (sports version). All of them deserve a lot of flattering reviews in terms of reliability and power, but a common disadvantage is the inevitable deformation of the valves when the timing belt breaks, which is fraught with a major restoration that requires huge expenses.

That is why it is extremely important for the owner to detect signs of imminent belt breakage in time and replace it with a new part.

Preparing to replace the timing belt

Replacing the timing belt on an 8-valve engine begins directly with removing the terminals from the battery, after which we remove the generator drive belt. To replace the belt, you must have full access to the necessary components. To achieve this access, it is necessary to remove the front right wheel.

Replacing the belt is preceded by disassembling the timing mechanism itself, namely removing its front top cover. Why is such an event held? It is necessary to set the first piston to the TDC (Top Dead Center) position.

Adjusting the tension roller nut

It is the appropriate adjustment of the tension roller, or rather the use of the Lada Granta timing belt in a fixed tension, that determines the service life of the Lada Granta timing belt.

To dismantle a used or broken timing belt, it is necessary to loosen the tension roller nut, as a result of which the belt will be brought to a weakened position. After this, you can proceed to the next stage.

Important: do not try to simply cut the belt so as not to unscrew the tension bolts. In this case, you will not be able to put a new belt on the shafts

Generator drive pulley: unscrew the main bolt of the generator pulley

You can unscrew the bolt of the generator pulley using ordinary keys, which were mentioned above in the list of necessary tools. If the bolt does not come out of the generator pulley, then you must perform the following steps:

• dismantling the plug in the clutch housing

• the flywheel teeth are fixed with a mounting blade, the presence of which was justified by the list of necessary tools.

After performing these steps, the generator pulley bolt will stop turning, since the crankshaft will be fixed with a mounting blade.

• Removing the generator pulley

The generator pulley must be dismantled immediately after removing the mounting blade. After dismantling is completed, the pulley must be placed on a clean surface. The presence of debris in the unit assembly can cause it to jam.

• dismantling the lower timing cover

The process of dismantling the lower timing cover is carried out by removing three mounting bolts. This design occurs in engine models Grants 21116, as well as.

• dismantling the timing belt

The last stage is dismantling the timing belt and then determining the condition of the tension roller. The belt removal process occurs in the following order:

• removing the timing belt from the timing pulley

• removing the belt from the crankshaft.

It is at the second stage that the Grant timing belt is dismantled along with the tension roller. We carry out a visual inspection of the roller, in particular, we determine the external condition and the level of play of the mechanism.

At the time of reinstalling the lower timing cover, it is necessary to adjust the tension of the belt itself.

The reasons for premature belt breakage on the Lada Grant remain a mystery, which is based not only on the poor quality of the material used in the belt, but also on the low quality of assembly of the aggregate units through which the timing belt passes.

Among other reasons for premature timing belt breakage, one can note the desire of the car manufacturer to keep up with Euro 3/4. It was the desire to adjust the car to these standards that led to the above-mentioned negative aspects in the daily operation of the car.

Despite the manufacturer’s claims about the quality of Grant’s timing belt and the threshold of his personal mileage of 200,000 thousand km, it breaks already at 70–80 thousand km. A Gates roller belt can be a good and worthy replacement solution.

It is the Lada Granta from Priora that the timing belt will fit the Lada Granta and will not cause premature failure. The price of a timing belt for a Grant allows it to be changed every 50,000 thousand km, which, in turn, will reduce the likelihood of other cost items arising regarding the repair of engine valves.

Replacing the belt on an 8-valve Lada Granta engine. Detailed description

After making sure that the part is in poor condition, you need to prepare for the procedure of replacing the timing belt on a Lada Granta 8 valve. First of all, you need to provide a comfortable place to work, well lit, spacious enough and safe.

Tools you will need:

- Wrenches included in the set

- Heads with extension

- Mount

- Special device for adjusting the roller

The tensioner pulley is often replaced at the same time, so it is necessary to purchase it in advance. In all stores you can buy a timing belt pulley for Granta as a set.

Before starting work, you must unscrew the ground wire from the battery.

Let's consider the process of replacing the timing belt on a Lada Granta car using the example of an 8-valve engine. Main stages of work:

Preparing for repairs. The car is jacked up and the front wheel is removed from the right side, as well as the protection that blocks access to the engine.

Removing the protective cover. On Grant cars, the plastic cover consists of two parts. It's easy to remove. First you need to unscrew the 4 bolts of the upper part, and then the lower part.

To do this, you need to use a 5-point hex key. In addition to the cover, you also need to remove the crankshaft position sensor by simply disconnecting it from the connector and removing it from the socket.

Alignment of marks. Before replacing the timing belt on Granta 16 and 8 valves, it is necessary to correctly set the engine valve timing. To do this, you need to turn the crankshaft clockwise. This is done using a 17-inch socket. You need to turn it until the mark on the camshaft toothed pulley coincides with the mark on the inner surface of the timing cover.

In addition, the marks must line up on the engine flywheel. This can be checked through a special hatch in the upper part of the clutch housing. After removing the rubber plug, you need to make sure that the special protrusion on the flywheel coincides with the camshaft mark.

Only after this can you continue replacing the timing belt on the Lada Granta.

Removing the generator pulley. To prevent the shafts aligned to the marks from turning, the flywheel can be locked through the inspection hatch. The most convenient way to do this is with a thick screwdriver or pry bar. Having firmly secured the flywheel, carefully unscrew the nut holding the generator pulley and remove it along with the washer.

Next, loosen the generator pulley nut

Adjusting the tension roller. Using a 15mm wrench, you need to gradually loosen the tightening of the roller mounting bolt. When the fastening is loosened enough to allow sagging, you can begin dismantling, making sure once again that all the marks match.

Withdrawal. The part is carefully removed from all pulleys and removed from the engine compartment. If there is a complete break in the timing belt on Grant's car, this is even easier to do.

Installation of a new spare part. Before use, the timing belt on Grant 8 valves is checked for manufacturing defects - peeling, cracks, excessive roughness of the material. It would be useful to look at the expiration date, since rubber loses its properties even without being used, but after lying on the shelf for several years. The number of teeth on the Lada Granta belt with an 8-valve engine is 113, and its width is 17 mm. Installation of the part is carried out in the reverse order. First, it is pulled onto the crankshaft, then onto the generator and pump, circling the roller, and at the very end - onto the camshaft. Tension. To ensure good tension, you need to rotate the roller counterclockwise. This is done using a special key, which consists of 2 metal rods. These are inserted into the corresponding holes on the roller and the roller is rotated until the cutout on the roller cage aligns with the rectangular mark on the inner sleeve. Only after this can the roller bolt be tightened.

In order to understand the sequence of work, we present to your attention an explanatory video about where to look for tags:

Why and when you need to change the timing belt

As is clear, the timing base is the camshaft, which is located in the cylinder head and pushes the intake/exhaust valves. The camshaft is driven from the crankshaft by a drive belt. Timely opening and closing of valves must be carried out in a strictly established order and in accordance with the engine operating cycles.

In other words, during the intake stroke the intake valve must open, so air or a fuel-air mixture (depending on the type of engine) enters the cylinders. Next, the consistency is compressed (the piston moves to TDC), at this moment all valves are closed. After the fuel charge is ignited and useful energy is released to the piston, the exhaust valve opens to remove exhaust gases from the engine cylinder. This is how the gas distribution process is carried out.

It becomes clear that any malfunction of the camshaft drive will lead to disruption of gas exchange in the cylinders, as a result of which the operation of the engine will be disrupted. As for the timing belt, this element is a rubber product that stretches, cracks, etc. over time. Belt slippage causes the valves to stop opening at the correct moment in relation to the engine operating cycles. Moreover, for many engines, a broken timing belt is especially dangerous. The fact is that if the belt breaks, then the gas distribution mechanism stops, the valves simply do not have time to close before the piston rises, an impact occurs, after which the valve usually bends, defects appear on the piston itself, etc. In such cases, the power unit needs to be repaired, and the repair itself will require significant financial expenses.

You should also take into account a number of reasons that can significantly reduce the service life of any belt. For example, engine oil getting on the timing belt as a result of leaks in the crankshaft front oil seal can quickly render the designated camshaft drive element unusable. Problems with the tension roller, jamming of the pump and other malfunctions are the reasons why the belt breaks or wears out quickly.

If signs of wear on the timing belt are noticeable or the time for its scheduled replacement is approaching, then it is not much to simply install a new element. When replacing, the belt should be set correctly. To replace and expose, you need to prepare tools; it is also better to service the car on a lift or in a garage with an inspection pit. The smallest set for this operation can be considered a jack, screwdrivers, spanners and socket wrenches, a socket wrench, preferably a wrench with a socket head, etc.

Read:

The car does not start after replacing the timing belt, timing chain or carrying out other work on the gas distribution mechanism drive. Main prerequisites, advice.

Timing belt malfunctions on Grant and methods of elimination

Failures of the distribution device in advanced cases can lead to failure of the power plant. This can be avoided if you inspect all gas distribution elements in a timely manner and correct defects and breakdowns in a timely manner.

Main symptoms of malfunctions and procedures

| Cause | Remedy option |

| The engine does not develop maximum power, insufficient dynamics. | |

| Violation of the gaps between the pusher and the camshaft cams. | Adjusting the gaps. |

| Gap between seat and valves. | Grinding seats, replacing valves. |

| Engine operation is unstable and often stalls. | |

| Violation of the clearances of pushers and cams. | Adjusting the gaps. |

| Valves burnt out or deformed. | Replacement of worn elements. |

| Oil consumption has increased. | |

| Worn or deformed valve gaskets. | Replacing gaskets. |

| Worn valves or guide bushings. | Replacing valves or guides. |

| Valves are knocking. | |

| Large gap between the camshaft cams and the drive levers. | Set the correct gap. |

| The spring has failed. | Change the spring. |

| Large gap between rod and guide. | Replacement of worn elements, repair and grinding of cylinder head. |

| Camshaft cam wear. | Replacing the camshaft. |

| The drive belt is noisy. | |

| The belt tension has weakened. | Pull the belt. |

| Worn tensioner roller. | Part replacement. |

| The tensioner rod is jammed. | Remove the jam. |

| The camshaft is noisy. | |

| Camshaft cams and levers are worn. | Replacement. |

| Bearings are worn out. | Replacing bearings. |

| The compression in the cylinders is reduced. | |

| Valves burned out. | Install.new.valves. |

| Loose fit of valves to seats. | Grinding of seats and valves. |

Diagnosing timing belt faults is a complex procedure. Signs may also indicate other components and assemblies. To accurately determine the cause of the failure, it is necessary to dismantle the cylinder head. In a private garage, this procedure is quite labor-intensive, and you also need to have special skills and equipment.

Risk of a faulty timing belt for the engine

A timing drive failure can have serious consequences. At the very least, the engine will fail. And the best way to fix this problem is to contact a car service center.

The severity of the consequences of this failure depends on whether such a case is provided for by the engine manufacturer. On some models, when the belt breaks, the valves collide with the pistons in the combustion chamber. These elements are destroyed, after which the engine may become unsuitable for repair.

Some manufacturers make recesses in the pistons for valves or make a specially shaped combustion chamber in case of a belt break. In such motors, “meeting” does not occur. And all that is needed is to install a new belt and adjust the valve timing correctly.

The Auto-Master car service center (gate No. 5) will replace the faulty timing belt on your car with a written guarantee of the quality of the work performed! Make an appointment with us by phone or using the form below.

The timing belt of any modern engine is usually designed for a short service life. On average, it operates for 50-100 thousand kilometers, after which it requires replacement along with the tension rollers, and often also the water pump and pulleys. The timing of replacement of this important part is strictly regulated and specified in the operating instructions for each specific vehicle. However, by blindly following the manufacturer’s recommendations, you may not notice the impending disaster and run into serious and expensive engine repairs. There are several signs that the timing belt urgently needs to be replaced with a new one.

Why do you need to change the timing belt?

First, let's figure out what a timing belt is and why it needs to be changed. This inexpensive and uncomplicated, at first glance, part is needed in order to synchronize the operation of the ignition system with the stroke of the pistons and valves. The timing belt rotates on the crankshaft and camshaft (or camshaft) pulleys, simultaneously driving the water pump. It has a multi-layer reinforced structure and consists of rubber and nylon base. The correct belt tension is set by a special roller. When the timing belt breaks on most modern cars, the intake and exhaust valves meet the pistons. A serious breakdown occurs that is incompatible with further movement and requires complex, expensive repairs.

The timing of replacement of rubber products and related components depends not only on the make and model of a particular car, but also on operating conditions, which in our country are very harsh. However, this does not prevent some brands from installing prohibitive timing belt service life on their products. For example, on domestic Ladas this operation should be carried out once every 180 thousand km. This figure looks, to put it mildly, too high. For comparison, on Renault cars, even the highest quality belts from the world’s best manufacturers last 60 thousand km in Russia and 120 thousand km in Europe. Experiments with non-compliance with this regulation are fraught with big troubles.

Signs of timing belt wear

The main problem that prevents you from noticing impending trouble in a timely manner and preventing the timing drive from breaking is difficult access to the part: unlike the belt of mounted units, this belt is carefully covered with all kinds of casings. To perform an inspection, partial disassembly of the engine is often required, which most car owners are not able to perform. However, in addition to tears and cracks that are visible visually, there are other symptoms of impending disaster. We will try to list the most common ones.

1. Belt is old

Basically, the service life of a timing belt is determined by the mileage of the vehicle. After several tens of thousands of kilometers, it must be replaced. However, there is one “but”: age is also critical for this part - on average, the belt retains its properties for no more than five years, after which it begins to lose elasticity and crack, regardless of mileage. Drivers who drive a car relatively rarely should pay close attention to this point. The belt consists of materials that are subject to rapid aging, which means you shouldn’t joke with its age. For the same reason, we recommend that you change the timing belt on purchased used cars without fail - no one guarantees that the previous owner complied with the regulations and used high-quality components.

2. Uncertain engine start and loss of power

Checking the timing belt

According to the documents that come with the car, the belt synchronizing the movement of the shafts has a service life of 45 thousand kilometers. However, it may fail even earlier due to increased load or insufficient attention to the car engine.

A performance check should be performed every 15 thousand kilometers. To do this, you need to remove the cover from the timing belt drive.

- First of all, check the belt tension adjustment tab: the cutout of the inner roller disk should coincide with the tab located on its rectangular plug. Even if the differences are minor, this consumable must be replaced.

- Then inspect the external part of this Lada Grant component. Make sure there are no signs of wear, oil, sludge, threads.

- At the end, the belt must be integral, without any separation into layers and fibers.

The Lada Granta has an eight-valve engine with 87 horsepower installed in the elevator housing. When the timing belt is damaged on this engine, the valves on the pistons are bent, putting you at risk for difficult engine repairs.

When purchasing the component, please note that Grant uses a 113 tooth belt that is 17 millimeters wide. Replacing a faulty component with the proper selection won't be needed anytime soon, so take a good look at the new part before purchasing

Automotive enthusiasts recommend purchasing Gates spare parts from the USA. The good thing is that official support can tell you the address of the nearest store where they sell high-quality spare parts. The price of a repair kit (belt and roller) is about 3,000 rubles. At the same time, you will receive a high-quality product, the resource of which is approximately twice as long as that of stock one (about 80 thousand kilometers).

Replacing the timing belt Lada Granta 8 valves

If you have the skills and necessary tools, you can check the condition and replace the Grant timing belt yourself in a regular garage. Replacing the Granta 8 valve timing belt includes: preparing the car for repair work, removing the belt, installing marks, installing a new belt, roller if necessary, etc.

Replacing the timing belt on a Grant itself requires the presence of certain tools:

- spanners;

- mount;

- heads with extension;

- special tool for adjusting the roller;

- Grant timing pulley complete with timing belt.

As for the stages of work, replacing the Grant timing belt is carried out in the following order:

Signs of a Worn Belt

You can avoid expensive repairs by monitoring the condition of the parts in the timing mechanism drive. This will make it possible to timely detect the beginning of the process of destruction of parts in the drive and prevent the creation of a situation where motor repair is required. First of all, pay attention to the condition of the product and its wear. If wear is high, heavy loads or high ambient humidity can cause the belt to slip.

Increased wear can cause deviation towards the tension roller and strong heating due to a failed bearing. Protruding shreds of drive material indicate that wear has begun. The owner should be alarmed by the appearance of cracks; the greater the number of such damages, the shorter the remaining service life of the product. If the outer side of the belt appears shiny, it indicates a loss of elasticity and must be replaced. If the drive has lengthened to such an extent that its tension cannot be adjusted, the belt must be replaced.

Timing belt replacement

This operation can be either planned or forced. In the first case, the belt can be replaced when it has exhausted its service life, and in the second, when damage to the working fluid of the product has been identified. A trained driver can do it independently. The operation is performed in a garage or on a level area. You will need a set of wrenches and sockets. And you also need to purchase a set of Torx keys. You will have to work with your hands in cramped conditions, so you will need gloves. You will need a car jack, a reliable stand under the car body, and wheel chocks.

On 16-valve engines, unlike 8-valve engines, two camshafts are installed, not one. And there is also an additional adjusting roller for belt movement.

Before starting work, disconnect the terminals from the battery. If the car has additional equipment (air conditioning, power steering), you will first have to remove their drive belt, which will not allow replacement of the timing drive. To do this, loosen the tensioning device, after which the drive of the auxiliary mechanisms is easily removed.

The timing mechanism drive is covered with protective plastic covers, which should also be removed. You will need a T-30 wrench with a ratchet, which is used to remove the fastening bolts first on the top cover, then on the bottom casing. Removal of the lower casing is hampered by the tensioner of the auxiliary drive belt, which must be lifted up. After this, the drive mechanism will be open.

Now you need to set the timing drive to the marks; this should be done in order to prevent damage to the valves.

Shaft lock in action

The next step is to remove the pulley on the engine crankshaft. To do this, keep the crankshaft stationary. You can do this:

- Raise the right side of the car with a jack and place the body on a stand. The wheel is removed from the car hub.

- The assistant gets behind the wheel of the car, engages fifth gear, and presses the brake pedal.

- The owner uses a 17mm socket to unscrew the pulley on the crankshaft.

Next, you should release the tension roller fastening (located on the right side in the direction of travel of the machine), after which the timing belt is removed.

After this, replace the rollers if necessary.

Install the timing belt in reverse order.

Tags

In order to obtain all the characteristics of the power unit laid down by the designers, it is necessary to achieve coordinated operation of all components and assemblies of the automobile engine. The valves (inlet or outlet) must open at the right time. To do this, installation marks are applied to the engine housing, camshaft pulleys, and crankshaft. There is a housing on the cylinder head to protect the timing drive. There are two cone-shaped slots on it, opposite which there should be marks for the camshaft pulleys.

Camshaft marks for 16 valve engine

On pulleys, the mark can be in the form of a cone-shaped recess or a protrusion on the underside of the crown of both parts. There is also a mark on the crankshaft pulley that should match the mark on the cylinder block.

Crankshaft mark

All three pulleys must align perfectly with the timing marks on the block and cylinder head guard. The camshaft gears should be secured against possible rotation. There is a special device for this, but you can simply hammer a suitable size wooden block between them.

Tension

The degree of tension of the belt drive is adjusted by a tension roller. It has marks on the housing and the moving race of the bearing, which should be aligned after installing all the timing drive parts in their places. To do this, you can use a wrench or pliers to remove the circlips. The cage is turned counterclockwise until the movable and stationary marks on the roller coincide, after which the bolt securing it can be tightened.

Mechanism assembly process

All manipulations are carried out in reverse order.

- We make sure that the marks are located correctly.

- Install a new tension element (roller).

We start hanging the belt by putting it on the crankshaft gear. Then, supporting the “consumable” with your hand, we “throw” it onto the splines of the camshaft gear. The last step is to tighten the belt with a roller. This element is equipped with a pair of holes into which it is possible to insert a fork or, alternatively, pliers to fix the eccentric in a tensioned position of the belt. Tighten the bolt while holding the roller.

We make sure that replacing the timing belt in the LADA Granta car was successful by rotating the mechanism two full turns (manually). We check the alignment of marks and marks (on the flywheel and viewing window).

Let us note one nuance: there may be a deviation of a couple of millimeters from the marks on the camshaft relative to the mark applied to the head housing of the Lada Granta block. This one is allowed. If the discrepancy is equal to 10 mm, then incorrect installation of the belt is immediately visible. To eliminate it, loosen the roller and move the belt 1 tooth in the required direction. Once the correct installation is achieved, we continue further assembly.

When replacing the timing belt that drives the generator unit, we take into account the fact that there is no tension mechanism. For tensioning purposes, we bring the device body as close as possible to the motor block. After this, we put the belt on the generator pulley completely, but partially on the crankshaft pulley. By subsequently turning the shaft, the belt is put on the designated pulley with your own hands.

At this point, the replacement of the timing belt is completed and the Lada Granta is ready to start the engine.

A similar replacement of the timing belt in 16-valve engines has a number of differences listed below.

- Since the timing belt has two camshafts on the Lada Granta, there are also two marks on their gears. Both should be checked for correct installation.

- Two rollers must be replaced: a bypass roller and a tension roller.

- The procedure for attaching the belt is more painstaking, since it involves taking into account the correct placement of the belt on the teeth of both camshaft gears with preliminary passing of the branch past the roller, which serves as a guide.

- Please note that the area of the motor head located under the shaft gears is dirty. If such a fact is present, wipe the area and the inner surface of the protective casing.

Replacing the timing belt Lada Granta liftback 8 valves

- We place the car within the perimeter of the repair area, squeeze the handbrake, open the hood, and the gearshift lever in the “neutral” position;

- We reset both terminals from the battery to avoid a short circuit in the network;

- Remove the decorative plastic panel in the timing belt area;

- Using a flat-tip screwdriver, make marks on the outer perimeter of the gear and the cylinder body (block);

- By rotating the crankshaft pulley, we align the actual mark with the dead center;

- We tear off the crankshaft pulley mounting nut;

- Unscrew the tensioner pulley mount, reduce the belt tension, unscrew the generator mount, remove the belt from its seat on the pulley;

- We carry out troubleshooting and assess the condition of the teeth. If there is no deformation, replace it with a new belt. We will also inspect the cooling system pump; its operation should be quiet, without noise or wedge. The presence of the opposite indicates a malfunction and the need for prevention;

- Upon completion, we assemble the structure in the reverse order with the obligatory installation of new components.

To make sure that the process was completed successfully, turn the crankshaft pulley 1 - 2 turns. The rotation should be relatively easy. We check the matches of the marks. A deviation of 1 - 2 mm is allowed, no more. Self-replacement of the timing belt Lada Granta liftback is over.

Design features of the drive of different motors

To understand how maintenance work is performed on the timing drive, let’s first consider its design.

So, the gas distribution mechanism is driven from the crankshaft. In this case, the valve timing in the engine cylinders has 4 cycles and they are performed in two full revolutions of the crankshaft.

But 2 of these cycles occur with the valves closed, so the camshaft must ensure only one closing and opening of the valves during all 4 cycles.

Therefore, for two revolutions of the crankshaft, only one revolution of the camshaft is made. Moreover, this is achieved quite simply - due to the different diameters of the drive toothed pulleys.

The belt has a toothed working surface, which prevents it from slipping on the pulleys. In addition to transmitting force from the crankshaft, the belt performs another function - it drives the cooling system pump.

In this case, the drive must be constantly tensioned to prevent the teeth from jumping on the pulleys, which is why a tension roller is included in its design.

This is the entire drive structure, that is, it includes only two toothed pulleys (crankshaft and camshaft), a pump gear, a tension roller and the belt itself.

All this is located on the side of the engine, not inside. But to prevent the ingress of dirt and technical fluids that could harm the belt, all elements are covered with protective shields.

But this describes the design of a gas distribution mechanism with 8 valves, which is driven by only one camshaft.

But some Lada Granta models are equipped with engines with a 16-valve timing mechanism and two camshafts. But because of this, the drive design does not change much.

Unlike the 8-valve, there is not one, but camshafts and, accordingly, two toothed pulleys, and another roller has been added to the design - a bypass roller, also known as a support roller. That's where all the differences ended.

conclusions

Now you know how long to change the timing belt. Undoubtedly, a broken LADA Granta belt is a source of unprecedented problems. This circumstance does not mean that you need to remain inactive. Below are a few recommendations whose goal is to minimize this risk.

1. Be very careful when checking the belt for wear. This action is recommended to be carried out after 10-15 thousand km.

2. Do not neglect checking the condition of the seals. The defect manifests itself in the form of characteristic spots under the bottom of the car.

3. The flashing of the lamp that registers the oil pressure in the LADA Granta engine may indicate a problem. If this fact manifests itself, we urgently turn off the engine and take measures to find the source of the breakdown.

4. Use only original spare parts, although no one has canceled the procedure for monitoring their condition.

How to correctly diagnose timing belt?

To check the condition of the elements included in the gas distribution mechanism, the periodic interval is 15 thousand km. The procedure looks like this:

- The right front side of the car is supported by a jack to allow the wheel to be rotated by hand.

- We engage 4th or 5th gear in the gearbox.

- Remove the plastic cover that protects the pulleys and timing belt from contamination.

- We rotate the suspended wheel using manual force, which allows the crankshaft to perform a similar rotation. During this time, we study the degree of wear on the belt surface on both sides.

When defects are found on the belt that look like:

- peeling of the rubber coating;

- broken teeth of the working surface;

- cracks on the back side

Then the timing belt needs to be replaced, regardless of the mileage.

If the tension force weakens, the belt requires immediate tightening. During the implementation of the verification process, it will not be superfluous to inspect the belt that serves to drive the generator, the scheduled replacement frequency of which does not exceed 30 thousand km.

Most experts recommend replacing the belt in the timing drive unit every 50 thousand km. This is caused by the service life of the cooling system pump, which rarely exceeds the designated mileage interval. In this unit, the bearing is susceptible to failure, which leads to jamming of the shaft.

When instantaneous overloads occur, the belt breaks without any alternative, and this causes unforeseen consequences of damage to the motor. The greatest impact of a “catastrophe” may be the moment at which a belt break occurs at the moment the piston moves to TDC. As a result of the fatal meeting of the pistons with the valves, the latter bend, and the engine awaits a “grand” repair. And you can’t fix anything here with your own hands.

Some general provisions about the belt

The timing belt in any engine serves to ensure timely intake of the prepared mixture and release of exhaust gases. The composition of this node implies the presence of the following elements:

- camshaft and crankshaft;

- the valves themselves with seals, springs, guide bushings and other parts.

Which timing belt is better? The belt mechanism is positioned separately in this mechanism, acting as a connecting link between the camshaft (or two) and the crankshaft. It is the belt drive that is able to ensure synchronization in the functioning of the elements included in the timing kit.

Finding this important element on the engine will not take much effort. To do this, you just need to open the hood of the Lada Granta and you will see it covered with a special casing. This protection prevents contamination and the entry of foreign objects and dirt.

The design of the belt mechanism includes a rubber base and a working inner surface made in the form of teeth with a certain pitch size.

Price: 800 rubles

The belt is in branded cardboard packaging, on the box there is a sticker with a QR code. The kit includes a sticker that indicates the date of replacement and mileage, as well as which of the components - roller, belt, pump - were replaced. This is convenient: you won’t have to struggle to remember when the last belt replacement was made and what exactly was replaced. In addition to branded and general designations, the belt is marked with a batch number.