09.20.2021 10 329 Cylinder block

Author: Victor

Domestic cars have a fairly simple design, which allows them to be repaired on their own. Replacing the Kalina cylinder head gasket can be done independently, but only if you have a garage, a good set of tools and the owner has experience.

[Hide]

Frequency and signs of replacement

There is no specific time frame for replacing the cylinder head gasket on the Lada Kalina. Over time, it can become unusable under the influence of various factors. The gasket can break through in different places and, depending on the location of the crack, the signs of damage will be different. The symptoms will be the same for both 8-valve and 16-valve engines.

Symptoms of gasket damage:

- When the gasket breaks along the side of the cylinder circumference, gases begin to escape outward. At the same time, the noise level of the VAZ Kalina engine increases sharply, which will be immediately noticeable to the driver.

- A hole between the cylinders disrupts the operating mode and the engine begins to operate unevenly and triple.

- Destruction of the gasket with a rupture entering the coolant supply channels. At the same time, gases begin to enter the cooling system. One of the external signs of such a problem will be a decrease in the fluid level and the appearance of white steam in the exhaust gases. Gas bubbles may appear in the expansion tank. Another sign is the appearance of an emulsion in the oil, accompanied by an increase in the level of lubricant in the crankcase. Oil can also go into the cooling system, which is easy to detect by its presence on the surface of the liquid in the expansion tank.

- Another indirect symptom of a gasket burnout is the appearance of stains or leaks of oil or coolant on the parting line of parts and on the side surface of the engine crankcase.

Replacement process

The replacement process itself on the Kalina 8 cl unit is simple and can be carried out under normal conditions, in the most ordinary garage with good lighting. When dismantling, place all removed parts in some previously prepared container so as not to lose anything. If the car has high mileage, you may need to purchase new bolts for tightening. But it will be possible to say more definitely after dismantling the head.

Required Tools

One type of torque wrench

- a set of keys;

- set of heads;

- hexagon;

- durable screwdriver.

- The first step is to remove the casing of the 8 cl power unit.

- The number one cylinder piston should be set to the top dead center position.

- De-energize the system by disconnecting the negative battery cable.

- Drain the coolant.

- Disconnect and set aside the air filter element.

- Disconnect the heating hoses, other pipes and connectors.

- Don't forget to disconnect all the wires from the spark plugs.

- Next, remove the cylinder head cover.

- Remove the camshaft drive cover located in front.

- Insert a screwdriver into the hole in the pulley hub to prevent the camshaft from turning, and loosen the bolt securing the timing pulley.

- Next you need to remove the timing belt.

- Completely unscrew the bolt that secures the camshaft pulley.

- Remove the pulley.

- Next, you need to remove the camshaft drive cover, which is located at the rear.

- Remove the remaining pipes and wires.

- After disconnecting all the wires and pipes, you need to loosen the bolts that secure the cylinder head of the viburnum 8 class.

This is done strictly according to the scheme. Be sure to strictly adhere to this diagram when loosening the bolts - Next, you need to completely unscrew the cylinder head mounting bolts.

- They are removed along with the washers.

- We remove the cylinder head.

- It is worth knowing that during long-term operation, the bolts with which the cylinder head is secured increase in length. Therefore, it is better not to save money, but to install new ones.

- Before installing new bolts, they must be lubricated with oil.

- We remove the Kalina cylinder head gasket.

- The place where it was installed must be cleaned. This is done not mechanically, but using a special liquid. If you use a file or a wire brush, there is a high risk of scratching the surfaces. As a consequence, loss of tightness with all the ensuing consequences.

The surface was polished with an abrasive tool. Scratches are noticeable. Install a new gasket.New part installed

- We install the cylinder head. Make sure the crankshaft and camshaft are at top dead center. This is a very important condition.

- We insert bolts into all holes and tighten them in a certain sequence:

Diagram for tightening the bolts. - First, we walk around the first circle and pull, applying a force of 20 N•m (2 kgf•m);

- Then we go around the second circle and pull, applying a force of 69.4-85.7 N•m (7.1-8.7 kgf•m);

- Next, use a wrench to turn the bolts 90 degrees;

- We go through it again and turn it 90 degrees again.

- Next, you need to connect all the removed wires and pipes. Many car enthusiasts, performing this work for the first time, mark the parts or take photos.

Stages

Power point

At this point, the replacement of the cylinder head gasket on Kalina with an 8-cl unit is completed. The process cannot be called simple, but requires special care and accuracy. If, after reading the material and viewing the photo gallery, you still have questions, watch the video material.

Gasket selection

When purchasing a gasket, you need to know the type of engine installed on Kalina. There are two versions of 8-valve engines - VAZ 11183 and VAZ 11186. These engines have different piston groups and differ in many external elements. On the older version 11183, a thickness of 1.2 mm is used (article 21080-1003020-12, manufacturer ZAO Lada-Image), and the new 11186 requires a gasket with a thickness of only 0.43 mm. This nuance must be taken into account when choosing new parts. For a 1.4-liter 16 valve engine, a gasket 11194-1003020-00 manufactured by Federal-Mogul Corporation is required, or you can get a cheaper option from Trialli (GZ1015001).

How to replace it yourself?

Replacing a burnt gasket requires a large amount of work. Self-repair and replacement of the Kalina cylinder head gasket can only be carried out by an experienced car owner who has the skills to disassemble and reassemble engines. For novice drivers and people who are not confident in their capabilities, contacting a specialized service would be an advisable step.

Tools and materials

Before starting work, you need to find a room for the replacement and check the availability of the necessary tools and equipment.

The minimum set of tools and spare parts is as follows:

- new cylinder head gasket;

- 10 bolts for cylinder head with size M12 (article 026707, for motor 11183) and M10 (article 256632, for engine 11186);

- gasket for the junction of the catalytic converter and resonator housings;

- torque wrench up to 100 Nm;

- a set of hex keys and sockets (at least sizes 10, 13, 17 and 19);

- pliers;

- screwdrivers with different types of blades;

- rags for wiping;

- container for draining coolant.

It is not recommended to use old cylinder head bolts.

Step by step instructions (8 valves)

After preparing the tools, you can begin replacing. The gasket replacement procedure is quite lengthy and takes about 8-9 hours even for experienced craftsmen.

Below is an approximate sequence of actions when replacing the cylinder head gasket of a Kalina with a 1.6-liter 8-valve engine:

- Place the car over the inspection hole.

- Remove the fuse box cover located on the center console and remove the fuel pump fuse.

- Start the engine and drain fuel from the ramp. Turn off the engine.

- Disconnect the battery and remove it from the vehicle.

- Replace the fuse and cover.

- Unfasten the decorative plastic casing from the motor. To do this, you need to pull it up and pull off the rubber caps from the studs. Inspect these caps; damaged parts should be replaced.

- Remove the three bolts securing the upper part of the camshaft drive belt housing.

- Separate the cover and manually turn the engine crankshaft to TDC (top dead center) in the first cylinder. The guideline will be the coincidence of the notch on the camshaft gear with the notch on the rear of the housing.

- Remove the plug located on the clutch housing and check the location of the mark on the flywheel and housing. The marks must match.

- Secure the engine flywheel with a screwdriver through the hole in the crankcase and unscrew the camshaft gear.

- Remove the timing belt drive.

- Remove the ignition coil attached to the bracket with four screws.

- Remove the engine sump protective shield. Drain the coolant from the cylinder block. To do this, you need to open the expansion tank cap and unscrew the screw plug on the side of the crankcase. Pour the liquid into a prepared container.

- Disconnect the lines from the thermostat and throttle valve assembly.

- Separate the air duct from the throttle body and remove the air filter housing.

- Step by step disconnect the electrical wiring connectors for the idle speed (IAC), throttle position (TPS), fluid temperature and oil pressure sensors.

- Disconnect the ground wire from the engine.

- Disconnect the injector connectors.

- Remove the fitting and separate the fuel supply pipe from the ramp.

- Remove the two bolts securing the ramp to the intake manifold housing.

- Carefully move the ramp along the axis of the injectors and remove them from their seats on the manifold.

- Remove the brake booster hose attached to the throttle body fitting.

- Unfasten the intake pipe spacer mounted on the nuts.

- Remove the lambda probe connectors on the catalytic converter.

- Unscrew the receiving pipe going to the muffler from the flange of the gas neutralizer.

- Remove the neutralizer support bracket.

- Loosen the head bolts according to the diagram and unscrew them completely. When removing bolts, they must be removed along with washers.

- Remove the head from the engine.

- Remove the old gasket.

- It is advisable to send the removed head for surface milling, since it may have microcracks that arose when the engine was running with a broken gasket.

- After checking, you can put the head back, having first checked the presence and completeness of installation of the guide bushings.

- Thoroughly wipe the mating surfaces of the block and head from oil and coolant. Clean the bolt wells from liquids.

- Carefully wash the cylinders with gasoline to remove deposits.

- Place a new gasket on the block, centering it along the guide bushings. The channel for the passage of oil through the gasket is located between the third and fourth cylinders - it is important not to miss this moment.

- When reinstalling the head, it is necessary to set the position of the shafts corresponding to TDC in the first cylinder (according to the marks).

- Tighten the bolts according to the scheme in several passes - initial tightening with a force of 20 Nm, tightening with a torque of 70–85 Nm, the first turn by 90 degrees and the second turn by another 90 degrees. When installing the head, use only new bolts and lubricate them with a thin layer of engine oil, which will facilitate tightening.

- Reinstall all removed parts.

- During assembly, it is recommended to check and adjust the valve clearances, as well as check the tension of the drive belt and the correct timing of the gas distribution mechanism.

- Turn the assembled engine over by hand several times and re-check the timing timing.

- Start the engine, make sure there are no leaks or extraneous sounds. Warm it up, visually monitoring its condition.

- Remove the coolant pipes from the throttle body assembly. Release the air from them, gradually increasing engine speed. Put the tubes back on and add fluid to the tank to the normal level.

Sequence of loosening bolts

Bolt tightening order

Video from the channel Sdelaj Sam! Pljus interesting! Demonstrates basic methods for identifying faults and replacing worn parts.

Step by step instructions (16 valves)

Removing the head for replacement on such motors has its own characteristics that must be taken into account during disassembly and reassembly. The engine design is much more complex than the 8-valve version and requires careful assembly and subsequent adjustment of the valve timing.

How to remove the head from a 1.4-liter 16-valve engine with an injector, model VAZ 11194:

- By analogy with an 8-valve engine, it is necessary to drain the fuel from the line, remove the battery, decorative casing, and air filter. And also drain the coolant and disconnect all sensor connectors.

- Remove the breather pipe and vacuum booster hose.

- Disconnect the hoses from the throttle body and the throttle position sensor.

- Remove the ignition coils.

- Disconnect the wiring harnesses and fluid supply pipes from the windshield washer reservoir. Remove the tank itself.

- Loosen the tension on the accessory drive belt and remove it.

- Remove the camshaft drive belt guard and fuel rail. The injectors are removed using a scheme similar to the 8-valve engine.

- Move the generator towards the radiator and remove the oil level dipstick guide.

- Remove the receiver mount to the block head.

- Unscrew the lower timing belt cover.

- Unscrew the fastenings of the timing belt tension rollers and the crankshaft pulley and remove them together with the belt.

- Remove the camshaft gears.

- Unscrew the 15 bolts and remove the camshaft cover.

- Unscrew the 20 bolts that secure the camshaft supports.

- Remove the shafts.

- Remove the hydraulic compensators.

- Unscrew the attachment points of the neutralizer to the head.

- Disconnect all hoses from the thermostat.

- Unscrew the 10 head mounting bolts (according to the diagram).

- Remove the head and replace the gasket.

- Reassemble, taking into account the recommendations for the 8-valve engine.

Head removal procedure

Bolt tightening order

Video “What to do if the gasket between the cylinders burns out”

This video shows the burnout of the gasket between the cylinders of a Lada Kalina with an 8 cl power plant. This material will also be necessary for those who have a problem with the cylinder block gasket. It shows many of the steps and techniques required not only to install a new gasket, but also to maintain this unit in working order. Remember that, first of all, in order for this unit to serve you for a longer time, it is necessary to comply with and carry out on time all service measures specified by the manufacturer.

If you detect a leak of engine oil on the Lada Kalina engine (11194 1.4 16 cl.) coolant at the junction of the head with the cylinder block, remove and replace its gasket. A leak may also occur due to warping of the head due to overheating. You will need: torque wrenches “13”, “17”, “19”, socket heads “10”, “13”, “17”, wrench 10mm hexagon, screwdriver. 1. Remove the decorative engine casing (“Removing and installing the decorative casing of the Lada Kalina engine”) 2. Install the piston of the 1st cylinder to the piston TDC compression stroke (see “Installing the 1st cylinder to the TDC compression position”). Reduce the pressure in the power system if work is performed immediately in step 3. Reduce the pressure in the power system (see “Reducing fuel pressure in the power system”).

4 Disconnect the wire from the negative terminal of the battery.5. Drain the coolant (see “Replacing the coolant”).6. Remove the air filter (see “Removing and installing the air filter”).7. Disconnect the heating hoses, the small branch of the crankcase ventilation system, the canister purge, the air supply hose, the wiring harness blocks of the throttle position sensor and the idle speed regulator from the throttle assembly (see “Removing and installing the throttle assembly”).8. Remove the throttle assembly (see “Removing and installing the throttle assembly”).9. Disconnect the wiring harness connectors from the ignition coils. Remove the ignition coils and unscrew the spark plugs (see “Replacing and servicing spark plugs”).10. Disconnect the wiring harness connectors from the emergency oil pressure drop sensor, from the engine management system coolant temperature sensor and the phase sensor.

11. Loosen the clamps and disconnect the five cooling system hoses from the thermostat pipes.12. Disconnect the wiring harness connector from the coolant temperature gauge sensor.

13. Using a 13mm wrench, unscrew the nut securing the tip of the “mass” wire and remove the wire.14. Remove the intake manifold (see “Removing and installing the intake manifold”)

15. Unscrew the screw of the pressure plate of the bracket securing the fuel line to the cylinder head and remove the plate.

16. Using a 10mm wrench, unscrew the fastening bolt and disconnect the earth wire from the block head.17. Remove the cylinder head cover (see “Replacing the cylinder head cover seal”).

18. Using a 5mm hex key, unscrew the fastening bolts and remove the front protective cover of the timing belt.

19. Using a 5-point hex key, unscrew the bolts securing the lower front timing belt cover and remove the cover.

20. Using a 15mm wrench, loosen the bolt securing the tension roller and remove the timing belt.

21. While holding the camshaft pulleys from turning, unscrew the bolts securing the pulleys, remove the pulleys...

22. ...and remove the keys from the grooves of the shaft shanks

23. Using a 15mm wrench, unscrew the fastening bolt and remove the tension roller.

24. Using a 15mm wrench, unscrew the fastening bolt and remove the support roller.

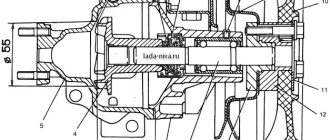

25. Using a 10mm wrench, unscrew the five bolts securing the rear protective cover of the timing belt and remove the cover.Fig. 6.3. Tightening procedure for cylinder head bolts

26. Using a 10mm hex key, unscrew the bolts securing the cylinder head to the cylinder block in the reverse order of tightening (Fig. 6.3) and remove the cylinder head.27. Remove the head gasket.Note The cylinder head bolts will stretch with repeated use, so replace them with new ones.28. Clean the mating surfaces of the cylinder head and cylinder block (they must be dry and clean).29. Remove oil from the threaded holes in the block for the head bolts.

30. Check the presence of two installation sleeves in the sockets of the outer holes of the cylinder block for the head bolts. If, when removing the head, the bushings remained in the head or came out of the block sockets, press them into the block until they stop.31. Install a new head gasket onto the block. The use of a used gasket is not permitted. Before installing the gasket, it is necessary to remove oil from the mating surfaces of the block and its head. The gasket must be clean and dry. Oil should not come into contact with the surface of the gasket.

Fig 6.3 Procedure for tightening the cylinder head bolts

32. Install the head on the block, first making sure that the crankshaft and camshafts are in the TDC position (both valves of the 1st cylinder must be closed). Tighten the cylinder head mounting bolts in the sequence (shown in Fig. 6.3 in four stages: 1 - torque 20 Nm (2 kgf*m); 2 - torque 69.4~85.7 Nm (7.1 - 8 .7 /N*m)3 - tighten the bolts 90°; 4 - finally tighten the bolts.

33. Install the removed parts onto the cylinder head and connect hoses and wires to it in the reverse order of removal. Installation of the intake camshaft ensuring the operation of the sensor to the engine. Install the intake camshaft pulleys in the same way. Adjust the tension of the timing belt (see “Replacing the timing drive and tension roller”) and the generator belt (see “Checking the tension of the generator drive”). Note: Before installing the cylinder head, apply Loctite sealant to the bearing housing - 574." It is allowed to start the engine no earlier than an hour after applying the sealant. For replacing the cylinder head gasket for an 8 valve engine, see the article “Replacing the cylinder head gasket for a Lada Granta”

Price issue

Changing the head gasket yourself will be quite inexpensive, since its cost ranges from 220 (for 8-valve engines) to 550 rubles (for 16-valve engines). In addition to it, you will need a gasket between the exhaust pipe and the catalyst, which costs no more than 100 rubles, and 10 new head bolts, costing 40–50 rubles each. Often the manifold gasket is damaged, which in this case must be replaced. A new part costs about 750 rubles. The total cost of spare parts will not exceed 1,500 rubles. It must be remembered that when disassembling and troubleshooting the engine, other parts may appear that need to be replaced.

Performing such work at a service station depends on the territorial location and ranges from 4 thousand rubles in small cities (Tula, Bryansk) and up to 10 thousand rubles in large cities (Moscow, St. Petersburg).

Removing and disassembling the cylinder head

We remove the cylinder head to replace its gasket, valves, their guide bushings, repair the head, and also when completely disassembling the engine. The cylinder head can be removed assembled with the receiver, intake pipe, fuel rail and catalytic collector or by first dismantling these components. We show the removal of the cylinder head assembly with the above components. We carry out the work on an overpass or inspection ditch. Remove the engine screen. Relieve the fuel pressure in the power system (see “Replacing the fuel filter”). Disconnect the wire terminal from the negative terminal of the battery. Disconnect the fuel supply hose from the fuel rail tube (see “Checking the injectors, removing the fuel rail and injectors”). Drain the coolant from the engine (see “Checking the level and replacing the coolant”). Remove the air filter (see “Removing the air filter”). Remove the vacuum brake booster hose from the receiver pipe (see “Removing the receiver”). We disconnect the tips of the high-voltage wires from the spark plugs (see “Checking the condition and replacing the spark plugs”).

Using the “13” head, unscrew the nut securing the tip of the “negative” wire to the cooling system thermostat housing. . and remove the wire tip from the stud. Loosen the clamps.

. Remove the cooling system hoses from the cover and thermostat housing. We remove from the throttle assembly fittings the hose that drains coolant from the assembly heating unit and the hose of the solenoid valve for purge the adsorber. Disconnect the air supply hose from the throttle body pipe (see “Removing the throttle body”). We disconnect the engine management system wiring harness connectors from the fuel injector wiring harness connector (see “Checking the injectors, removing the fuel rail and injectors”) and from the idle air regulator (see “Checking and removing the idle air regulator”), as well as from the sensors: — throttle position (see “Removing the throttle position sensor”); — phases (see “Removing the phase sensor”6); — coolant temperature (see “Removing the coolant temperature sensor”); — oxygen concentration (see “Removing the control oxygen concentration sensor”). We disconnect the wire blocks from the coolant temperature indicator sensors (see [[115-2 Kalina Repair|“Removing the coolant temperature indicator sensor”) and the emergency oil pressure (see “Replacing the emergency oil pressure sensor”). By loosening the lower fastening nut and unscrewing the upper fastening nut of the coolant pump pipe bracket, remove the bracket from the cylinder head stud. We dismantle the left and right support brackets of the intake pipe (see “Replacing the gasket of the intake pipe and catalytic collector”). We disconnect the additional muffler pipe from the catalytic collector (see “Removing the additional muffler”). Remove the cylinder head cover (see “Adjusting thermal clearances in the engine valve mechanism”). Remove the camshaft gear pulley (see “Replacing the camshaft oil seal”).

Using a 10mm wrench, unscrew the nut of the upper fastening of the rear timing belt cover.

Using a 10mm hexagon, unscrew the ten screws securing the cylinder head. Remove the screws and washers.

We remove the cylinder head assembly with the receiver, intake pipe, fuel rail and catalytic collector (it is more convenient to remove the head with an assistant).

Remove the cylinder head gasket. If it is necessary to disassemble the cylinder head, we dismantle the receiver (see “Removing the receiver”), the intake pipe and the catalytic collector (see “Replacing the gasket of the intake pipe and catalytic collector”). Remove the camshaft (see “Removing the camshaft”). Marking the installation location.

. remove the valve tappets with adjusting washers from the cylinder head sockets.

Using a 13mm socket, unscrew the two nuts securing the thermostat.

Remove the thermostat assembly.

. and its gasket. We unscrew the coolant temperature indicator sensor (see “Removing the coolant temperature indicator sensor”). We mark the valves with a marker

When disassembling the valve mechanism, place a stop (a wooden block) under the plate of the valve being desiccated. We dry out the valve (see “Replacing valve oil seals”) and remove the spring plate, outer and inner springs, and support washer.

We remove the valve from the guide sleeve. We dismantle the other valves in the same way. Before assembling the cylinder head, use a wire brush to remove carbon deposits from the surface of the combustion chambers. We wash the cylinder head with kerosene and blow out the oil channels with compressed air. We assemble and install the cylinder head in the reverse order. Before installing the valves, clean them from carbon deposits and apply a thin layer of engine oil to the valve stems. We clean the mating surfaces of the cylinder block, head and thermostat housing from the remains of old gaskets, dirt and oil. We remove oil and coolant from the threaded holes of the cylinder block for the head mounting screws. We install the new cylinder head gasket and the head itself along two centering bushings. Install the fastening screws and tighten them in four steps according to the diagram:

Procedure for tightening the cylinder head screws

first step - tighten the screws to a torque of 20-25 N*m (2.0-2.5 kgf-m); second step - tighten the screws to a torque of 70-85 Nm (7.0-8.5 kgf-m); the third step is to turn the screws by 90°; The fourth step is to turn the screws 90°. The cylinder head bolts can only be reinstalled if they have been extended to a length of no more than 135.5 mm. If the length is longer, replace the screws with new ones

I didn’t want to write a report on this topic, because... It’s not for me to teach engine rebuilding. And then I looked at the photographs and wanted to draw some conclusion from my experience. I'm sharing.

The car is 8 years old and has covered about 90 thousand km during this period. HBO was installed a year ago. Recently, after winter (although it wasn’t very good before), I noticed that the engine has become clearly less dynamic, the response to the gas pedal is no longer the same.

The temperature in winter reached -35 degrees per day. This is quite adequate compared to last year, when in the morning the readings on the dashboard were -40 degrees.

Photo gallery

The photo below shows some stages of replacing the gasket on an 8-valve VAZ engine.

Engine with valve cover removed

Unscrewing the exhaust pipe from the converter

Interior of engine cylinders with damaged gasket

The gasket itself

Place of gasket punching

Cylinders washed with gasoline

Head removed from engine

Carbon deposits on valves and combustion chambers

The photo below shows some of the stages of disassembling a 1.4 liter engine.

Removing the washer reservoir

Removed ramp with injectors

Probe guide

Timing drive removed

Camshaft gears removed

Removing the camshaft supports

Cylinder interior

16 valve head

Video

The video shows the identification of the malfunction and the process of changing a broken gasket on Kalina (by Sdelaj Sam! Pljus interesnoe!)

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (50.00%)

No (50.00%)

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 6 votes, average: 4.50 out of 5)

Discuss the article: