05/14/2021 14,005 VAZ 2114

Author: Ivan Baranov

While operating a car, some car enthusiasts are faced with the same important question, namely: how to remove the box on a VAZ 2114 or on another car of this AvtoVAZ line. The VAZ 2114 gearbox is the same as on the VAZ G8. The only difference is that the VAZ 2108 does not have a dipstick, and it accelerates faster.

The gearbox may need to be removed in a variety of cases, for example, in order to replace the clutch or something in its system, as well as to repair the gearbox itself.

[Hide]

CONSTRUCTION FEATURES

Structurally, the gearbox device is divided into 3 main parts: gearbox housing, rear cover and clutch housing. The internals of the device can be divided into two groups - the main pair and the differential with gear ratios.

The main pair, also known as the drive shaft of the gearbox, performs the function of reducing the speed transmitted from the engine to the crankshaft. The VAZ 2114 GP gearbox reduces engine speed by almost four times (gear ratio – 3.7).

Manipulations with the main pair, aimed at changing the gear ratio, allow you to change the length of the gears, which makes it possible to influence the acceleration and maximum speed of the fourteenth. However, it is not recommended to interfere with the operation of the box without proper qualifications - you can do irreparable things.

The VAZ 2114 gearbox that comes as standard has the following gear ratios:

- First speed – 3.636;

- Second speed – 1.95;

- Third speed – 1.357;

- Fourth speed – 0.941;

- Fifth speed – 0.784;

- Reverse – 3.53.

As evidenced by the reviews of the owners of the fourteenth, the standard gearbox is not the ideal of engineering thinking - the first speed is too short, the second, on the contrary, is long. Poorly selected gear ratios cause a serious loss of vehicle dynamics during acceleration when switching gears from 1 to 2.

The cost of a new gearbox for a VAZ 2114 is about 16 thousand rubles; used gearboxes can be found at prices ranging from 4 to 10 thousand, their price varies greatly depending on the condition.

Transmission malfunctions

First, it is worth considering faults that can be removed without dismantling. If the reverse gear does not press, it is worth checking the clamp and the mechanism itself for blocking. Another common problem is a rattling gearshift lever. The sound comes from a bushing that hits the surface of the wings. You can solve a manufacturing defect using a file - the error is determined and excess metal is removed.

It is recommended that you carry out the removal repairs together with a friend. During work, there will be times when you need to unscrew the fasteners both under the hood and in the interior of the VAZ 2114. It is also more convenient to check with an assistant whether the gearbox was installed correctly.

Repair and, accordingly, removal of the gearbox is required when, when changing gears, a grinding or crunching sound appears in the gearbox, a hum is heard, and the lever moves with difficulty. Also, dismantling is indispensable when some gears are switched off randomly (the problem is caused by a drive adjustment failure or a synchronizer failure).

POSSIBLE FAULTS

Despite the imperfect operation, the VAZ 2114 gearbox, when used correctly, is distinguished by good endurance and durability. If you do not hesitate to prevent and promptly eliminate breakdowns, repairing it is not expensive.

Let's consider the main gearbox malfunctions that the owner of the fourteenth may encounter:

- Lack of speed fixation when switching. If the speeds are out of whack, the cause is most likely worn teeth on the gears and clutch. Accelerated wear of these parts is caused by incorrect gear shifting and non-compliance with the speed limit. The problem is resolved by replacing the gears.

- The gear shift lever is tight. The reasons are mechanical damage to the teeth of the lever fixing on the hinge or wear of the reaction rod; it’s also a good idea to check the integrity of the plastic parts of the gearbox drive;

- The VAZ 2114 gearbox is humming. Most often, the gearbox is humming in neutral gear. First of all, you need to check and, if necessary, add oil (in general, the box may hum due to the use of low-quality lubricants). If the oil is normal, the problem is wear of the bearing on the input shaft, which can only be determined through diagnostics or by disassembling the gearbox;

- Crunching sound when changing speed. Here it is necessary to change the worn out synchronizer, and it must be changed immediately after the problem has been discovered, because if you tighten it, the gear unit will completely fly off;

- Knock. The gearbox on a VAZ 2114 can knock both under load and without it, and in any gear. The cause of the knocking noise is a damaged drive gear of the problematic transmission.

One of the key factors for the trouble-free operation of gearbox number fourteen is the use of high-quality lubricants. The most suitable option is GL-4 mineral oil. It is not cheap, but it does its job at 5+; when using mineral oil, VAZ gearbox repairs are usually required extremely rarely.

Most VAZ 2114 owners agree that the best gearbox oil is 75W90. It is distinguished by greater fluidity than typical gearbox oils, due to which the lubricant better gets into those places of the gearbox, the lubrication of which is provided exclusively by splashing. Good options for 75W90 are Hypoid-Getriebeoil TDL and Liqui Moly Vollsynthetisches Getriebeoil (GL-5).

Checking the oil level should be carried out every three weeks. In the gearbox, the fourteenth gear is placed vertically, the topmost is the fifth, it is the one that is most susceptible to failure due to lack of lubrication, so it is always necessary to fill in oil to the maximum mark, and best of all - 200-250 ml. more than the required norm.

Failures that do not require removal of the gearbox

If the reverse gear does not engage, then it is not necessary to remove the box: it does not have a synchronizer installed, the problem can be solved more simply. Before making a decision, you need to check the universal joint and the linkage, as the problem may be caused by a loose clamp. Another reason could be that the mechanism is blocked.

To check, remove the lever between the seats and visually assess whether there is a problem. The same operation must be performed if there is a crunching sound when engaging 2nd gear, since the most likely cause of the malfunction may be a worn synchronizer, which in the Lada Samara family of cars is not very durable.

Do I need to remove the gearbox if the gearshift lever rattles? This question worries many, but most often, removing the gearbox will not be necessary to fix the problem. An unpleasant sound occurs when the bushing that connects the rod and rod touches the wings of the latter. The metal bushing rattles due to frequent impacts on the metal of the wings. The defect of the VAZ 2114 manufacturer can be easily eliminated with your own hands.

According to reviews from car owners, this simple step eliminates the rattling of the gearshift lever. Handle vibration disappears. It will move stiffly, but it will gradually loosen and work easier.

REMOVAL AND REPAIR

Almost any DIY repair of a VAZ 2114 gearbox - installing new bearings, clutch or gears - involves removing it. To do this, you will need screwdrivers, a set of wrenches, WD-40 and hanging equipment to lift the unit.

Let's figure out how to remove the gearbox of the fourteenth:

- We drive the car onto an overpass or into a garage with a pit. First of all, we disconnect and remove the battery, then drain the oil from the gearbox and remove the starter. To do this, you need to disconnect the power wires from it, remove the protective jacket, unscrew the two fixing nuts from the bottom (from the pit) and one from the top of the starter;

- Now you need to remove the connecting cable from the clutch release fork and remove it from the bracket on the gearbox;

- Disconnect the wiring to the speed sensor. The wire block is secured by a spring, which must be compressed to disconnect the connection;

- We climb under the fourteenth and disconnect the wiring from the reverse sensor;

- We tighten the bolts with which the jet thrust bracket is attached to the unit body;

- We remove jet thrust. To do this, you need to loosen the clamp connected to the rod and move it back, which will make it possible to remove it from the hinge;

- Now you need to dismantle the wheel drives: remove the left one completely, and simply unscrew the right one, move it to the side and hang it on the car body;

- We unscrew the bolts from the ball joint (left) that secure it to the steering knuckle;

- We dismantle the gearbox mount to the engine on the lower right side; to do this you need to remove the supporting brackets from the stud;

- Remove the clutch housing cover (it is secured with 3 bolts);

- Unscrew the bolt on the lower left gearbox mount;

- Unscrew the nuts that secure the left and rear engine mount;

- Now we remove the fixing bolts with which the gearbox is attached to the rear engine support. We dismantle the support itself;

- Using a screwdriver as a lever, insert it into the hole between the engine cylinder block and the clutch housing, and move the gearbox off the guides as far back as possible. The rear part of the box body should pass on top of the suspension extension, and the input shaft will be disconnected from the clutch, after which the unit can be removed from under the car.

Now you know how to remove the VAZ 2114 gearbox. Good luck with your driving without any breakdowns!

Preparatory work

Before starting work, the car should be placed on an inspection ditch or driven onto an overpass and make sure that the raised hood is secured and the car is on the handbrake. During work, the engine will need to be suspended.

Therefore, you should provide the opportunity to install a hoist or use improvised means, a special device (crossbar to support the engine). To repair a VAZ 2114 gearbox, you need the following tools:

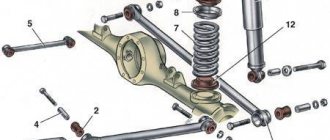

Transmission device: 1 - input shaft; 2 - secondary shaft; 3 — rod for shifting the third and fourth gears; 4 — fork for shifting third and fourth gears; 5 — differential; 6 — fork for switching first and second gears; 7 — fork rod for shifting first and second gears; 8 — gear shift rod; 9 — fifth gear shift fork rod; 10 — gear shift mechanism; 11 — reverse intermediate gear; 12 — clutch housing

It is more convenient to carry out work on removing the VAZ 2114 gearbox together with an assistant. First you need to disconnect the battery and put it aside. Drain the oil from the gearbox, having previously warmed it up, to do this, drive about 5 km before repairing.

With the car installed on the overpass, unscrew the 3 bolts securing the crankcase protection and remove it, remove the dipstick to check the oil level (in models produced earlier than 2003) or unscrew the oil filler plug. Place a container under the oil drain hole, use a 17mm wrench to unscrew the plug and wait until the oil is completely removed from the gearbox.

Remove the engine starter by sequentially disconnecting the column of wires, unscrewing the fastening nut and removing the wire on the contact bolt of the starter relay under the hood of the car. Go down under the bottom and remove the unit fastenings, then unscrew the last fastening again under the hood. Remove the starter from below.

Disconnect the speed sensor wires under the hood by compressing the spring holding the block. Disconnect the reverse sensor wires from below. Under the hood, unscrew bolts 1-3 connecting the gearbox housing and the ignition module bracket. Disconnect the torque rod bracket, loosen the gear shift rod clamp and remove the speed selector rod hinge rod.

To do this, you need to move it back a little. Remove the left front wheel drive and install a plug in its place. It is enough to disconnect the right wheel drive from the box and move it to the side, securing it in this position. Remove the left ball joint bolts that secure it to the steering knuckle.

Removing the gearbox

If all the steps described above have been completed correctly, then withdrawal can begin. The process goes as follows:

Unscrew the gearbox bolts

We hang up the gearbox and remove it

When the work is completed and the box is completely dismantled, you should disassemble it and check the parts for wear. If possible, repairs and replacement of damaged elements are carried out. In some cases, the problem can be solved by replacing bearings or seals, rather than purchasing a new gearbox.

Source