The VAZ 2114 has an injection engine with a volume of 1.5 and 1.6 liters. Such engines are equipped with a large number of sensors, as well as electronic fuel supply under pressure. Quite often it happens that a breakdown occurs in a car and fuel stops flowing to the engine, thereby preventing it from starting. It is quite difficult to find the cause of a fuel pump failure on your own, but after studying our article, you can easily determine the culprit of the breakdown and solve the problem as soon as possible.

In this article we will talk about the breakdown of the fuel pump on a VAZ 2114, namely why this part stopped pumping fuel.

Design and principle of operation of the fuel pump

In order to find the cause of the breakdown, you must first know the design and operating principle of the fuel pump.

Design

The gasoline pump is made of many parts and resembles an electric DC motor. Its body is made of plastic and metal; inside the body there is a magnet and a rotor, on the shaft of which an impeller is mounted on one side, and a current collector on the other. The fuel pump itself is a brushed motor, which greatly reduces its reliability; many modern cars (foreign cars) have already switched to brushless electric pumps.

One of the important elements of the pump is the check valve, which maintains the built-up pressure in the system and does not allow it to flow back into the tank through the valve.

Principle of operation

When voltage appears on the fuel pump block, it begins to rotate, the impeller pumps fuel into the system, as soon as it reaches the required amount, the fuel pump valve closes, thereby closing the path to the outflow of fuel back into the tank. After which you can start the engine. You can clearly hear the operation of the fuel pump by turning on the ignition and listening to its operation. The fuel pump will make a characteristic squeak and stop after a few seconds - this will mean that the pressure has been pumped into the system.

Malfunctions

Malfunctions of the mechanical device include malfunction of the discharge or suction valve, damage to the diaphragm, deformation of the drive roller or rod, as well as wear of the adjusting gasket between the roller and the balancer.

In the electrical element, in addition to malfunction of the valves and damage to the diaphragm, there is also a failure of the solenoid valve and a break in the electrical circuit connecting the drive to the battery.

Fuel pump system

The fuel pump itself does not work; it is part of a special station, the so-called “fuel pump cup”. This part is a bracket for mounting the fuel pump in the tank. Also, a special coarse fuel filter is put on the fuel pump, which allows you to keep the fuel pump from dirt getting into it. A fuel level sensor and a fuel pressure regulator are installed on the glass. Together, all these parts form the fuel pump station, or popularly the “glass”.

Preventing fuel pump breakdowns

The best prevention for long-term operation of the fuel pump is its careful and proper operation, as well as compliance with the following rules:

- All scheduled vehicle repairs must be accompanied by the replacement of all fuel filters.

- It is necessary to monitor and ensure the cleanliness of the fuel tank and filters, as well as monitor the quality of the fuel being refilled (the absence of water, sand and other impurities in it).

- Eliminate the possibility of water getting into the fuel tank.

- Protect the fuel pump housing from mechanical stress that causes dents and cracks that contribute to the development of corrosion processes.

Symptoms of a problem

There are many signs of a fuel pump malfunction and they are all similar to each other, and they can also be confused with breakdowns in other elements of the fuel system, such as injectors, filters, RTDs, etc. Signs of malfunction in fuel system elements are always similar, but the fuel pump has its own factor that can clearly indicate its malfunction - the sound of its operation.

Any pump, even the highest quality and new, should make a sound when operating. If there is no sound, then something is definitely wrong with the pump.

Possible symptoms of failure:

- Loss of vehicle dynamics;

- Difficulty starting the engine (the starter turns for a long time);

- The car stalls when you press the gas pedal;

All these problems can be caused by other fuel cells. For example, clogged injectors can also affect poor starting and loss of vehicle dynamics.

Characteristics of faults

There are several indicators according to which one can judge whether the fuel pump on a VAZ 2114 or its components are damaged. But at the same time, be sure to check whether there really is a problem with the fuel pump, because you can spend money on purchasing another one, but in reality it turns out that the problem is not in it:

- The motor does not start, this may indicate a malfunction in the pump. First you should check the functionality of the spark plugs to see if there is a spark. The electronic control system is also subject to verification.

- It is worth checking the pressure level inside the fuel system. When the fuel pump operates without interruption, a pressure of 3.2 bar is created. Based on the type of engine, the features of the fuel pump may vary:

- If the engine volume is one and a half liters, then the most acceptable value is 285-325 kPa.

- If the engine size is 2 liters, then the optimal indicators are from 375-390 kPa.

- There is no signal that does not reach the pump. This occurs when trying to start the engine. When the system operates correctly, starting the motor causes a slight vibration of the pump. If there is no vibration, then it makes sense to check the contacts.

- Trouble in the power plant is another not obvious sign of a problem with the fuel pump. But it’s better to check, as there is a possibility that the fuel pump is to blame.

- The motor jerks. This is also observed at low speeds and at the start. In this case, the problem may be a problem with the pump itself or with the mesh that requires replacement.

Most car owners purchase a complete fuel system, including a filter, sensor, float, intake chamber and pump. This acquisition costs around 3 thousand rubles. It is more profitable to buy one pump, the price of which is less than 1 thousand rubles. It happens that if the pump breaks down, the remaining components of the fuel system remain in good working order and are ready for subsequent use.

Checking the fuel pump

To check the fuel pump, you need to measure the fuel pressure in the fuel rail and check the pump itself for pressure “into the wall”.

To check the fuel pressure, you need a special device, a fuel pressure gauge; you can also use a regular pressure gauge with a hose, connecting it to the ramp through clamps.

- On a car with a 1.5-liter engine, the pressure in the fuel rail should be: 2.7-3.4 bar;

- On a car with a 1.6-liter engine, the pressure in the fuel rail should be: 3.5-4.0 bar;

Then the pressure of the fuel pump is checked, which it presses into the wall; for this it must be dismantled (on 1.5-liter engines you can simply clamp the return line). In this way, the power of the pump is checked when checking the pressure “into the wall”; a good pump presses pressure up to 8 bar.

Where is the mass of the fuel pump on the VAZ 2114?

Car owners drew attention to the fact that the mass is the “weak link” in the electrical circuit of the fuel pump. Unreliable fastening of the wires to ground causes the wire to heat up and burn out. The self-tapping screw on which the ground wire is attached must be unscrewed, cleaned and tightened again.

The mass of the fuel pump is located near the parking brake, nicknamed the handbrake by car owners. To get to it, you need to move the carpet a little to the side.

Why doesn't the fuel pump pump?

If the fuel pump has stopped pumping fuel pressure, then starting the car is out of the question.

Possible reasons:

- The fuel pump fuse has blown;

- The fuel pump relay burned out;

- The fuel pump burned out;

These three reasons are the main reasons why the fuel pump on a VAZ 2114 stops pumping fuel.

Finding the reason

The first thing you need to do is make sure there is voltage at the fuel pump, and it can go out for several reasons: a blown fuse or relay, burnt-out wiring.

Inspect the fuel pump fuse for integrity. It is located under the center console at the feet of the front passenger. It is necessary to remove the decorative cover of the leg air duct; there you can find three fuses and three relays. All of them must be intact.

You can check the relay using a multimeter by setting the switch to continuity, connect the probes to the relay coil, it should show some resistance. If the multimeter shows an open circuit, then the relay is faulty and requires replacement.

If the whole thing is most likely burned out, the fuel pump must be dismantled to do this.

How to change the pump

If it turns out that the relay for the VAZ 2114 fuel pump, the motor, the ground contact, and all other electrical elements of the circuit are working, all that remains is to replace the damaged pump with a new one.

You can do it like this:

- Disconnect the battery ground terminal.

- Drain the fuel from the tank.

- Remove the rear passenger seats.

- Remove the plastic cover covering the pump.

- Disconnect the wires and hoses going to the pump.

- Unscrew the fuel pump fasteners using a size 7 wrench.

- Remove the pump from the tank.

Installing a new fuel pump is done in exactly the same order, but in reverse order.

Problems related to the fuel pump

So, you need to analyze several symptoms of the main breakdowns of the dozen injection systems. If the VAZ 2110 fuel pump activation relay is faulty, then when you turn the ignition key you will not hear the characteristic hum that comes from the rear of the car. It is quite possible that there has been a break in the power supply circuit of the winding of the electromagnetic device. Check if there is voltage on it. It is possible that the fuse may fail. Please note that if fuses burn one after another, you should not spend money on buying new ones, but look for the reason for this behavior.

If fuses constantly fail, then there is a short to ground in the connectors or wiring. Moreover, you need to look in that part of the circuit that is located after the protection device. It is also possible that everything is fine with the wiring, the relay works, but the VAZ 2110 fuel pump does not pump. The reason is a lack of power or a breakdown of the engine itself. Among the latter, we can highlight breaks in the rotor and stator windings and wear of graphite brushes. And one more thing I would like to highlight: monitor the condition of the filter (diaper), which is located at the bottom of the fuel pump. If it is in poor condition, then the injectors may become clogged and the motor may fail.

CHECKING WIRING CONTACTS

If the fuel pump does not work, do not rush to change it - perhaps the problem is in poor-quality wiring. There are 3 wires connected to the pump: to the gasoline level sensor, and positive and negative to power the motor.

No special tools are required to check the wiring - a regular 12-volt light bulb is enough. We connect the light bulb to the negative and positive wires of the pump, and turn on the car’s ignition - if the light blinks, then everything is fine with the wiring.

VAZ 2115 fuel pump fuse: Where is it located, is it lit, malfunctions

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

What functions does the fuel pump relay perform, signs of breakdown. Where is the fuel pump relay installed, how to properly check the fuel pump relay.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

Diagnose faults that may indicate problems with the fuel pump. Self-check of the device, measuring the pressure in the fuel rail.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

Table of contents

Where is it lit? How to determine the malfunction

Where is

1. The fuse that controls the fuel pump. Its current strength is 15 amperes.

A fuse is a small element whose task in the design of electrical circuits is to melt in the event of an overload. The device melts and the current-carrying circuit opens.

Using the example of a solution from the popular VAZ Priora model, we can superficially examine the design and operating principle of the fuse. The device is small, the outer casing is made of plexiglass.

There is a conductive element inside. Such an element is based on several plates, which are made of different materials. Between these plates there is a special low-melting material.

Electricity passes through the specified material, which allows the fuse to be an integral part of the electrical power supply circuit of the fuel pump. The fuses are specially marked in the form of the letter F. This designation indicates that the fuse element belongs to a circuit whose power is not large.

To calculate the current that certain devices are designed for, you need to divide the power by 220. The result will be a figure in amperes.

- If the fuse is blown, then such a malfunction is often caused by the following reasons:

- — short circuit in the electrical circuit;

- — failure of the fuel pump relay;

- - low quality of the fuse itself;

In other words, more often the fuel pump fuse blows due to faults in the electrical circuits or as a result of failure of the components of the pump power circuit. Note that situations also arise when the fuel pump fuse burns on its own, but this phenomenon occurs much less frequently with high-quality elements.

The fuel pump relay turns on the fuel pump and delivers fuel to the injectors. The safety relay is activated when the engine is not running and the ignition is on (the control unit does not receive speed signals).

This relay is switched off in the control unit via a safety switch and interrupts the power supply to the pump. For example, in the event of an accident, gasoline cannot flow into the engine. Checking the fuel pump is a job most likely reserved for service centers.

In this regard, to find errors, we will limit ourselves to the following points:

- — turn off the ignition;

- — disconnect the fuel supply line at the distributor, while preparing a rag for spilled gasoline;

- — even when the engine is turned off, a certain amount of gasoline may come out, since the system is under pressure;

- — turn on the ignition for a short time without turning on the starter;

- — if the pump does not start working, check the fuse or safety relay again;

- — if fuel does not flow, check the pump relay;

- — if the relays are working properly, the fuel pump should start working;

- - otherwise, remove the cover under the rear seat and carefully tap the pump housing with a small hammer - sometimes it helps;

- — check the correct connection of the wires to the fuel pump;

- - if the pump does not work, check the voltage using a diode bridge (a conventional test lamp can damage the control unit). Don't forget to turn on the ignition first;

- if the voltage is normal, it means the pump is damaged or there is an open circuit. The pump should be replaced with a new one.

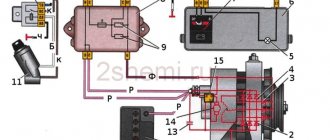

Full size

fragment of electric pump circuit

Attention, working with electrical equipment is dangerous. If you are unsure, seek the help of a qualified professional.

First of all, the driver should first remove the side console on the passenger side (there are 3 relays with fuses there). Our electric fuel pump relay is the lower one. (In some cars since 2007 there are 2 relays, but the fuel pump relay is the top one - see.

repair manual). Directly above the bottom relay is our fuse. The first step is to make sure that this fuse is working properly (photo stage 1).

If the fuse is working and its contacts and its connector are not oxidized, then you need to make sure that the relay is working properly. You can immediately install a known-good relay and turn on the ignition. If the situation is corrected, then install the side console and have a good trip.

If nothing has changed, then it is necessary to determine where the problem arose. To do this, you need to have a voltmeter or multimeter or a probe. But we will not determine the voltage value with a probe, and in this situation you need to know the voltage value - I’ll tell you why later.

The second step (photo step 2) is to determine whether there is control voltage at the fuel pump relay. We connect the multimeter, turn on the ignition and determine the voltage value. If there is no voltage, then there is an open circuit coming from the main relay or from the ECU.

If there is tension, then move on.

Stage 3 (photo stage 3) is to determine whether the power goes further directly to the fuel pump itself. If the power does not come out, the culprit is most likely the relay due to possibly burnt contacts.

If the voltage goes away, but its value is 10 volts, then most likely the relay contacts are also burnt. At this voltage, the pump motor will not start. We change the relay and check.

Next you will have to remove the rear seat to get to the electric fuel pump. We remove the hatch and see the fuel pump chip. There are 3 wires on the chip: 1-minus, 2-plus of the fuel level sensor, 3-plus of the fuel pump itself. Unfortunately, I won’t tell you the sequence and location on the chip yet.

In any case, when the ignition is on, there should be 2 pluses and one minus. In photo 4 (photo stage 4) we connect one by one to the contacts of the fuel pump chip and look at the presence and magnitude of the voltage.

If there is voltage, then the culprit is the electric fuel pump itself, and without removing it, most likely the cause cannot be eliminated.

Be careful with electricians and remember that the fuel pump control circuit can also break a faulty security alarm relay. Good luck to everyone.