FRONT SHOCK ABSORBER VAZ 2107

The suspension design of any car uses shock absorbers to increase the comfort and safety of movement. Since VAZ 2107 shock absorbers, like other suspension elements, are subject to constant loads and fail over time, you need to know how faults manifest themselves and be able to replace the part if necessary.

PURPOSE

The normal and correct operation of the front suspension of the “seven”, and the rear one too, is ensured by the main structural elements - a spring and a shock absorber. The spring softens the shocks of the body while the car is moving. When hitting any kind of obstacle (potholes, bumps), the wheel comes off the road, and thanks to the elastic element it returns to work. When the wheel hits the surface, the body presses down with its entire mass, and the spring should make this contact as soft as possible. The work of the shock absorber is aimed at dampening vibrations of the elastic element as quickly as possible when the body rocks. The part is completely sealed and, when fully operational, is capable of absorbing about 80% of impact energy. The shock absorbers of the front suspension of the VAZ 2107 are attached with the lower eye through the bracket to the lower suspension arm. The damper rod is fixed through the support glass using a nut.

Important elements of the front suspension are springs and shock absorbers

TABLE: PARAMETERS OF STANDARD FRONT SHOCK ABSORBERS FOR VAZ 2107

| vendor code | Rod diameter, mm | Case diameter, mm | Body height (excluding stem), mm | Rod stroke, mm |

| 21012905004, 21012905402 | 12 | 41 | 215 | 112 |

DEVICE

The front end of the VAZ 2107 comes from the factory with oil-filled twin-pipe shock absorbers. Structurally, in addition to the flask, piston and rod, they have another cylinder with a flask containing liquid and a piston element. During operation, the liquid is compressed by the piston, which causes it to flow through the valve into the outer cylinder. As a result, the air is further compressed. During rebound, due to the opening of the valves on the piston, the liquid flows back into the inner cylinder. This design of shock absorbers, although simple, has certain disadvantages. Since liquid from one flask to another passes through valves under high air pressure, aeration occurs, during which the liquid mixes with air, causing its properties to deteriorate. In addition, due to two flasks, the damper is cooled worse, which reduces its efficiency.

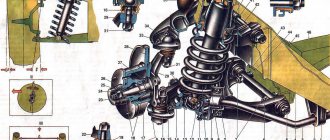

Design of shock absorbers of the front and rear suspensions: 1 - lower eye; 2 — compression valve body; 3 — compression valve discs; 4 — throttle disk of the compression valve; 5 — compression valve spring; 6 — compression valve cage; 7 — compression valve plate; 8 — recoil valve nut; 9 — recoil valve spring; 10 — shock absorber piston; 11 — recoil valve plate; 12 — recoil valve discs; 13 — piston ring; 14 — recoil valve nut washer; 15 — throttle disk of the recoil valve; 16 — bypass valve plate; 17 — bypass valve spring; 18 — restrictive plate; 19 - reservoir; 20 - rod; 21 - cylinder; 22 — casing; 23 — rod guide bushing; 24 — sealing ring of the tank; 25 — rod seal race; 26 — rod seal; 27 — gasket of the rod protective ring; 28 — rod protective ring; 29 — tank nut; 30 — upper shock absorber eye; 31 — nut securing the upper end of the front suspension shock absorber; 32 — spring washer; 33 — shock absorber mounting pad washer; 34 — pillows; 35 — spacer sleeve; 36 — front suspension shock absorber casing; 37 — rod buffer; 38 - rubber-metal hinge

Purpose of shock absorbers

Automobile shock absorbers (dampers) are a guarantor of driving comfort and safety. The main tasks of this element are to prevent the wheels from coming off the road, ensuring proper grip on the road surface and dampening body vibrations.

Twin shock absorbers on the VAZ 2107 provide proper traction

Such parts are most often replaced with spare parts of the same type, which can be purchased at automobile stores. Car owners determine the replacement period on their own, but do not delay this procedure, otherwise this can lead to premature wear.

Shock absorber design

The design of the damper depends on its type. The main part is a cylinder housed in a housing with ears. Inside there is a hydraulic composition (gas or a mixture of liquid and gas). There is also a piston connected to the rod. It contains the recoil valves and o-rings. With their help, the liquid in the cylinder is compressed and moves into the free space inside. The shock absorber is attached to the car body using a rod and a cushion, and to the suspension - using a cylinder. At the ends of the part there are special supports.

Design of single-pipe and double-pipe shock absorbers

The boot (casing) protects the inside of the cylinder and the rod from damage and dirt. To prevent liquid from spilling out of the cylinder, a special cuff equipped with a guide sleeve is attached to its upper part. The listed parts are included in the design of both the most complex and the simplest damper.

SHOCK ABSORBER FAULTS

Any car malfunction always manifests itself in the form of extraneous noise, unusual behavior of the vehicle or other signs. Problems with shock absorbers also have certain symptoms, and if they are detected, you should not delay replacing the dampers.

OIL LEAKING

The most common sign that a shock absorber has become unusable is a fluid leak. Leaks on the body indicate a loss of seal in the oil reservoir. As a result, not only leaks occur, but also air leaks. In this case, the damper rod has free movement, i.e. it moves without any effort, and the part loses its functionality. If signs of smudges have just appeared on the shock absorber, it will serve a little longer, but you should not leave it without attention and it is better to replace it in the near future.

The main malfunction of shock absorbers is leakage of working fluid

BODY ROLLING

Since springs and shock absorbers work together to dampen vibrations that occur when driving over bumps, contact with the road may be lost if the damper fails. In this case, shaking increases, the body sways, and the level of comfort decreases. The car becomes rolly, and when it hits obstacles it sways for some time. The easiest way to check the shock absorbers of your “seven” is to press the wing, try to rock the body, and then release it. If the car continues to swing on the springs for some time, then this is a clear sign of a faulty damper.

To check the shock absorbers, you need to swing the body by the fender or bumper

BODY ROLL

One symptom that indicates problems with the suspension shock absorbers is body roll when cornering. This behavior of the car negatively affects safety, since the quality of braking, as well as vehicle control, suffers. If liquid has leaked from the damper, it will be quite difficult to keep the car turning, which is especially dangerous in winter. When the mileage of the products in question is more than 60 thousand km, which also depends on the quality of the parts themselves and the operating conditions of the vehicle, handling may noticeably deteriorate. But since the process does not occur at one moment, but gradually, the driver practically does not notice this and rolls can be perceived as a normal phenomenon.

NOISE IN THE SUSPENSION

Extraneous sounds in the suspension, uncharacteristic of its operation, indicate the need to check and service this mechanism. When dampers and their bushings wear out, the ability to effectively support the weight of the machine is lost. In addition, so-called shock absorber breakdowns often occur.

Suspension breakdowns are metal elements touching each other, which leads to a knocking sound.

UNEVEN OR INCREASED TIRE WEAR

If it has been noticed that the tire tread has uneven wear or wears off too quickly, then this is a clear sign of problems with the suspension. With faulty shock absorbers, the wheel moves vertically with a much greater amplitude, which leads to uneven tire wear. When driving, extraneous noise appears on such wheels.

If your tires wear unevenly, one of the likely causes is problems with the shock absorbers.

DIVE WHEN BRAKING

Among car owners there is such a thing as “the car bites.” If the dampers fail, the front of the car will dive during braking, and the rear will sag when accelerating. This is explained by the fact that parts that have become unusable do not cope with their function, that is, they do not support the weight of the machine.

BREAKING ATTACHMENT

One of the infrequent breakdowns of the front shock absorbers is the breakage of the lower eye. The reasons for this phenomenon may be different:

- installation of low-quality parts;

- making changes to the standard suspension design.

Sometimes it happens that the fastening of the rod along with the glass breaks off. This phenomenon is accompanied by a knocking sound while driving. It is quite easy to identify a breakdown by opening the hood and looking at the place where the upper part of the shock absorber is attached.

When the upper shock absorber mounting cup breaks, a knocking sound appears in the suspension

The problem is resolved by welding. Some Zhiguli owners reinforce this part of the body with additional metal elements.

CHECKING SHOCK ABSORBERS ON THE STAND

The most accurate method for diagnosing shock absorbers is to test the car suspension on a vibration stand. Using such equipment, the properties of each damper are checked separately. At the end of the diagnostics, the device will display a diagram based on the results of measurements of axial vibrations. By comparing the diagram with the permissible vibration value of a working damper, you can understand the condition of the parts.

VIDEO: DIAGNOSTICS OF CAR DAMPERS AT THE STAND

Signs of Damper Failure

At speeds above 30 km/h, driving a car without shock absorbers is very problematic. Working parts are designed to control the wheel: it makes one movement up, one movement down, and the remaining energy (about 80%) is absorbed by the damper, turning into heat and dissipating in the air.

Properly functioning shock absorbers ensure safety, but not everyone is aware of this fact . The units wear out gradually, and this process is not accompanied by symptoms. The driver ignores the fact that his car has begun to behave differently - the result is an accident.

The higher the damper wear, the less contact the wheel has with the road surface. This leads to an increase in braking distance, a decrease in the speed at which the car can enter a safe turn, a hydroplaning threshold, and an increase in wear of the chassis and tires.

The ABS and Traction Control systems do not recognize faulty shock absorbers. Their sensors record the movement of the wheels along the track, and not their rotation in the air. As a result, the electronic control unit receives incorrect data and incorrectly transmits instructions to other mechanisms. Therefore, when determining the serviceability of dampers, the driver is forced to rely on his own feelings. The main signs of a breakdown are a decrease in ride comfort, the appearance of vibrations, and also the fact that the car begins to “knock .

SEQUENCE OF ACTION:

- we lift the VAZ 2107 car with a jack from the replacement side (we hang the rear wheel), not forgetting to tighten the hand brake;

- spray WD-40 on the mounting threads and go drink tea. After 15 minutes, the Teflon lubricant penetrates inside, which makes unscrewing easier.

- We begin to unscrew the bottom bolt, holding it on one side and using a ratchet on the other, and then knock the bolt out with a hammer through the plastic plate so as not to damage the thread.

- The bottom edge now dangles freely

- Now we calmly unscrew the upper fastening bolt with a wrench, and, using a pry bar, pry the cylinder to the side and remove it.

Now we move the jack to the second half and repeat the same steps.

You can use whatever you want - oil or gas, but be sure to use the same ones in a pair. This is how the rear shock absorbers are replaced. Front shock absorbers are replaced if the same symptoms occur: knocking and “breakdowns” when the front wheel gets into a hole, or the front suspension gets oily.

The tool you need are keys 6, 13, 17.

Checking the serviceability of shock absorbers

But before we describe the work process, we will consider ways to identify a shock absorber malfunction.

The first sign, as already indicated, is a knocking sound on one or both sides of the car when passing strong bumps.

A visual inspection will also help to identify the malfunction. Oil leaks can often be seen on the outside of the damaged element.

This indicates that the shock absorber has lost its seal and some of the oil is leaking out.

You can also assess the condition by rocking the body. To do this, you need to go to one of the front wheels and with both hands press firmly on the body to overcome the resistance of the springs.

You need to press several times to set the amplitude of oscillations as large as possible, and then suddenly stop swinging.

If the shock absorber is working properly, the body will immediately return to its original position, without any vibrations.

If there are vibrations, even minor ones, the shock absorber is faulty.

It is necessary to check by rocking on both sides of the car, since replacement must be done at least in pairs - two shock absorbers of the front suspension or rear suspension are changed at once. It's even better to change all the elements at once.

We will not consider replacing the rear shock absorbers for now; everything stated below will concern only the front suspension.

SEQUENCE OF ACTIONS IN THE FRONT:

We hang the wheel in front in the same way, then open the hood. There is access to the rod of the front shock absorbers of the VAZ 2107.

- Unscrew the nut using a 17 wrench and holding it with a 6 wrench.

- Then, from below, under the car, we turn out the bracket using a 13-mm open-end wrench and turn it out, and then remove it together with the shock absorber:

- Now we repeat all the steps on the other side, remove the second shock absorber, and then in the reverse order, just install new ones. For some car owners, on the contrary, it is easier to change one side first, so as not to jack the VAZ 2107 four times.

Replacement should ideally be carried out immediately at the front and rear to ensure maximum smoothness, but some “stingy” enthusiasts argue that such a replacement is more expensive.

Sources

- vaz.ru/remont/zamena-amortizatorov.html

- bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/peredniy-amortizator-vaz-2107.html

- zen.yandex.ru/media/uremont/zamena-perednih-amortizatorov-vaz2107–kak-zamenit-svoimi-rukami-5dfce19598fe7900ad9390b2?utm_source=serp

- drive2.ru/l/4951825/

- zen.yandex.ru/media/vaganov/zamena-perednih-amortizatorov-vaz2107-svoimi-rukami-5caa553a78ee6d00af774091

How to check if shock absorbers on struts need to be replaced

One of the easiest, cheapest and most effective ways to check dampers is a visual inspection. You may notice oil mist on the part, which should not be there. Lubricant leaks are a sign of depressurization and a signal that it’s time to change the component . If doubt arises during inspection, the shock absorber should be wiped clean and checked again after a few days of operation. They also look at the anthers and rebound buffer. Oil can contribute to the destruction of these parts.

An important step is to inspect the tires. If signs of wear are visible, especially uneven wear, then we can safely say that the dampers are faulty. You also need to check the stem of the part. If scratches from clamps or corrosion are noticeable on its surface, the shock absorber requires urgent replacement.

Traces of corrosion on the shock absorber rod indicate the need for urgent replacement of the part.

The most common is the car sway test. You can determine which shock absorber has failed by pressing on the corner of the car: where the part is faulty, the car will continue to oscillate. If the damper “stands up”, this indicates that it is jammed. It is advisable to carry out this test regularly .

Visual inspection of the vehicle's shock absorbers for faults

The vehicle's directional stability is also checked. At a speed of more than 80 km/h, the car begins to “scour” along the road, especially if there are uneven spots and holes on the road surface. The car's stability decreases.

When shock absorbers fail, there is a slowdown in the vehicle's response to the steering wheel - for example, the wheel is turned all the way, and the car is just starting to turn. Over time, the owner gets used to such changes, so you need to change parts yourself or go to a service center for diagnostics when the first symptoms appear.

Stands for instrumental diagnostics of dampers are of two types: vibration and test. When using the first type of stand, the car is driven onto a special platform, which, after a few minutes of testing, produces a diagram of axial vibrations. Experts, based on the data obtained and normal parameters for a particular model, determine the condition of the shock absorbers.

Checking car shock absorbers on a vibration stand

The second option involves completely disassembling the car’s suspension and removing parts. As a result of such actions, the most accurate information is collected, but such a procedure will cost a pretty penny. Bench testing of depreciation load is carried out mainly for diagnosing expensive components.

During bench testing, the shock absorber is disassembled into parts

Shock absorber design

The design of shock absorbers for any car, including AvtoVAZ products, is quite simple and consists of a cylinder with a rod filled with oil. It is known from a physics course that the liquid compressed by the piston rod is capable of damping shock vibrations and loads, and it is this principle that forms the basis for the design of this unit. In the VAZ suspension design of the “classic” layout, the shock absorbers work in tandem with springs, providing additional damping of vertical vibrations.

Recommendations

Comments 18

crappy oil... the shock is checked by machine, not by hand. although according to the symptoms the left one is a corpse. And then, are the shock absorbers oil or gas oil? plus, as a rule, performance is not the main criterion, the main criterion is the presence of oil in the shock absorber... there is no point in lubricating the silent parts with oil, they should not rotate at all when in place. like the metal bushing in the rubber band... looking at the rubber in general, a question arises. how did you travel? With such silents, the bridge dangles like shit from an ice hole, the car jerks from side to side when pedaling the accelerator.

How many people, so many opinions. In my opinion, the oil is good. It's not clear by car. According to the main methods of verification, it is alive, but rather harsh. Ammorts Niva oil. The car behaved stably, did not dangle anywhere, only rumbled sometimes. After the second trip I went to check and saw that my ears were hanging on the lower rubber bands. Well, I changed it right away.

We opened up a couple of engines using Lukoil oil... the bed, the head... everything was covered in an even 3-4 mm layer of soot. dirt just settles in the engine... because... many people say that nivo-shocks themselves are harsher than classic ones, although I don’t know... I haven’t used them... in any case, if they work differently, I would recommend changing them... maybe the speeds were low, since I didn’t notice...

crappy oil... the shock is checked by machine, not by hand. although according to the symptoms the left one is a corpse. And then, are the shock absorbers oil or gas oil? plus, as a rule, performance is not the main criterion, the main criterion is the presence of oil in the shock absorber... there is no point in lubricating the silent parts with oil, they should not rotate at all when in place. like the metal bushing in the rubber band... looking at the rubber in general, a question arises. how did you travel? With such silents, the bridge dangles like shit from an ice hole, the car jerks from side to side when pedaling the accelerator.

By the way, Lil Mobil Ultra, which you pour. It turned out to be complete slag. After 3 thousand I drained the black slurry and had to flush the engine. So, it depends. In Luka, I’m at least sure that this is factory oil, and not a broken badya in the basement of the Khachami.

Read also: M8v viscosity according to sae

Replacing front shock absorbers on a VAZ 2101-VAZ 2107

Car shock absorbers alone determine how the car will behave in the future on smooth and uneven roads. Over time, car shock absorbers deteriorate and therefore need to be replaced. In this article, we have written detailed instructions on how you can replace the front shock absorbers on cars of the “Classic” family.

To perform the replacement, you will need the following tools: First, be sure to stock up on a set of basic wrenches and new shock absorbers. And also, if you have one, take with you a special key for removing shock absorbers; for clarity, it is shown in the figure below:

Which shock absorbers do you prefer: “Gas-oil” shock absorbers or conventional “Hydraulic” ones? (Write your answer in the comments)

When do you need to change front shock absorbers?

They must be replaced if:

- Loss of its properties, that is, loss of efficiency in damping vibrations.

- And it must also be replaced with a new one if it starts to leak and as a result becomes oily.

To properly verify whether the shock absorbers are working or not, you can read the article entitled: “Checking shock absorbers for performance”!

How to choose shock absorbers

Choosing shock absorbers is not an easy task, since it is necessary to take into account a number of important factors that will subsequently affect the handling and service life of the car’s suspension. First of all, you need to pay attention to the following points:

- type of racks (gas or oil);

- length;

- permissible loads;

- compatibility with specific brands and models of cars.

The type of struts affects the stiffness of the suspension and its service life. Thus, gas struts are better suited for those drivers who prefer a more or less sporty ride and the most informative and “understandable” steering wheel. Installing oil-filled shock absorbers is more preferable for quiet motorists who use the car to perform everyday tasks.

Oil dampers are softer than gas dampers and provide comfort for the driver and passengers. Gas models are quite rigid, but this is a kind of payment for greater stability of the car on the road.

The length of the struts affects the vehicle's ground clearance. Installation of tuning models of struts with a lowering from -30 to -70 mm has a positive effect on the handling and stability of the car, as the center of gravity is reduced. There are models on the market with both factory length parameters and modified ones.

The permissible load indicator indicates how much the car can be loaded without compromising the condition of the suspension. As a rule, in expensive gas models this indicator is higher, which has a positive effect on the overall condition of the suspension and the service life of its parts.

How to remove and install the front ones

VAZ 2107 front suspension diagram

When starting the replacement process, you must first remove the old shock absorbers, and then begin installing new ones. To do this, you must perform the following procedures:

- Prepare the car for lifting using a jack, placing stops under the rear wheels to prevent it from rolling away.

- Open the hood of the VAZ 2107 and use a special wrench or pliers to fix the shock absorber rod to prevent it from turning during the dismantling process. After this, you need to unscrew the nut and completely dismantle the upper shock absorber cushion.

- Raise the car on a jack and unscrew the two nuts securing the bracket to the lever, then remove the shock absorber downwards. If you have difficulty loosening the nuts, it is recommended to use WD-40 fluid. The procedure should be performed carefully due to the presence of spring washers.

- After removing the shock absorber, remove the bottom cushion from the rod.

- Upon completion of the procedure, you need to unscrew the nut securing the bracket directly to the shock absorber. It is easier to do this by holding the bolt from possible turning with a second wrench.

- Install the new shock absorber in reverse order.

As you can see, parts can be changed without using a garage pit, but it is much more convenient.

Video on how to change

Replacing front and rear shock absorbers

Self-repair and replacement of shock-absorbing parts in a car suspension is not as complicated a procedure as it might seem at first glance. However, work related to parts that affect the vehicle's handling must be carried out with the utmost care.

When replacing “vital” elements, it is necessary to comply with all factory instructions and check the correct installation of spare parts several times. That is why, if one of the dampers on an axle (front or rear) breaks down, you should replace it with a pair, even if one (the other) is in good condition. The use of different struts on the same axle can negatively affect the vehicle's handling quality due to differences in stiffness and other performance properties.