VAZ 2109 fuel pump malfunction, types of VAZ gasoline pumps

On a VAZ 2109, signs of a fuel pump malfunction are a complete or partial cessation of the supply of gasoline to the carburetor, this entails the inability to start both a cold and hot engine, it will start and stall, in addition, unstable idling is possible. If you suspect that the fuel pump in the VAZ 2109 is not working, then you should check it. It's not difficult to do it yourself, just read this article.

Checking the fuel pump

So:

- Let’s immediately look at the two most common types of gasoline pumps, “Pekar” and DAAZ. They are installed on both rear-wheel drive and front-wheel drive cars. To check the serviceability and functionality of the entire fuel supply system:

- Remove the gasoline hose from the outgoing (discharge) fitting of the gasoline pump

- Then press the fuel pumping lever manually several times

- If the VAZ fuel pump is working properly, then a powerful stream of fuel should come out of the fitting

- If there is no stream, or there is a weak stream, perform a second check

To check the serviceability of the intake valve:

- We disconnect the fuel hose from the suction fitting of the pump (it turns out that now we have removed both fuel hoses from two fittings)

- Then we plug the suction fitting with our finger and press the lever for manual pumping several times

- At the same time, you should feel a vacuum on your finger (it should be sucked to the fitting)

- When there is a vacuum, this means that the fuel pump is working, look for faults in the gas tank or fuel lines

- If not, the fuel pump on the VAZ 21093 does not work, remove the pump, disassemble and change the intake valve

To check the exhaust valve for leaks:

- Place your finger on the hole in the injection fitting (the one that supplies gasoline to the carburetor), then press the lever several times to manually pump

- At the same time, a very noticeable stream of air comes out of the fitting hole, it pushes the finger away from the fitting

- If the stream is weak or absent, it means that the fuel pump on the VAZ 2109 does not pump, then remove the pump, disassemble and replace the exhaust valve

- If the filter is deformed or clogged:

- Remove the cap from the fuel pump, take out the fuel filter, clean it, rinse it in gasoline, then blow it with compressed air

- If the filter is deformed, then change it

- In the Pekar brand fuel pump, as well as similar pumps, the filter is removed by unscrewing the suction fitting from the cover, so you don’t have to remove the cover itself

- In case of malfunctions (leaky, torn) of the diaphragm:

A characteristic sign of such a malfunction may be the presence of fuel leaks on the fuel pump housing or the appearance of a gasoline smell in the engine oil. However, these signs may not appear:

- Remove the upper part (cover) of the fuel pump housing

- Take out his diaphragm assembly

- Unscrew the nut on the rod, then remove the diaphragms (there are three in total)

- Replace the diaphragms with new ones (you will need to purchase a repair kit)

- Then put everything back together, the diagram is in the photo below

Scheme of the diaphragm assembly

- The Pekar brand fuel pump has only one diaphragm.

- It can be removed after removing the cover.

- To disconnect the diaphragm assembly, rotate it 90 degrees.

If the valves are faulty, the VAZ 2109 does not pump the fuel pump, therefore:

- Remove the cap from the fuel pump, as well as the fuel pump strainer.

- Visually inspect the intake valve and fuel pump cavity

- Remove the upper body, inspect the exhaust valve

- When the valves are not pressed into the housing tightly or are not pressed tightly, or have lost mobility, then the pump must be replaced

- If blockages are found, they should be removed and then the housing should be blown out with compressed air.

- In the Pekar pump, both of its valves are located in the cover, so in order to assess their condition it is necessary to remove it from the body

- VAZ 21093 fuel pump does not work, if the pusher is damaged:

- Remove the fuel pump from the studs, while unscrewing the nuts that secure it

- At the same time, its gaskets, heat-insulating insert and pusher remain on the engine

- We rotate the crankshaft so that the pusher extends as far as possible

- You should measure how much the pusher protrudes above the plane of the topmost gasket

- The protrusion should be 0.8 - 1.3 millimeters

- When the protrusion of the pusher does not fit into the given size, then you should try to adjust it by selecting shims of smaller or greater thickness (depending on whether the length is not sufficient or it sticks out strongly) or change the pusher

- Replace only the outer thickest gasket located between the thermal insulation insert and the fuel pump

- Although repair kits for fuel pumps with ready-made gaskets are sold, you can also save money and cut it yourself from a piece of paronite

- If the spring under the diaphragm is broken:

- It is necessary to remove the upper part (cover) of the fuel pump housing, then remove the rod with diaphragms, carefully inspect the condition of the spring

- We replace broken, or compressed, lost elasticity

Fuel pump repair for VAZ 2109 (carburetor)

Content:

If the fuel pump on a VAZ 2109 malfunctions, the fuel supply to the carburetor is completely or partially stopped. Therefore, it is not possible to start the engine cold or hot. It will start at first, but then immediately die. Plus, instability at idle is often observed.

Before changing the fuel pump, it is recommended to first check the condition of the device. It is not uncommon for a breakdown to be corrected with minor repairs.

Checking the general condition of the fuel pump

First of all, let’s check whether the supply system of your VAZ 2109 is working at all. To do this, you need to take the following steps:

- Remove the pump fuel hose from the source or discharge fitting;

- Manually press the fuel pump lever several times;

- If the pump is operational, a strong stream of fuel will immediately flow through the fitting;

- If there is no jet or it is very weak, it will be necessary to carry out other checks.

Intake Valve Check

- Disconnect the hose from the suction fitting so that both hoses are eventually removed, each from its own fitting.

- Simply plug the suction fitting with your finger, then pull the lever several times to manually pump fuel. If everything works fine, your finger will begin to be sucked into the fitting. This effect indicates that the pump is working properly. Therefore, we look for the problem in the tank or lines.

- If there is no suction, you will have to disassemble the device to replace the inlet valve. Its tightness is most likely broken.

Leak test

To check the tightness of the intake valve, you must:

- Place your finger on the hole from the injection fitting and pump up the fuel several times using manual pumping;

- In this case, a stream of air should come out of the hole, significantly repelling the pressed finger;

- If the stream turns out to be weak or does not exist, the fuel pump simply does not pump.

In this situation, there are two options - look for the problem inside the fuel pump device, disassembling the pump, or change the entire unit.

The filter is clogged or damaged

To fix the situation, you need:

- Remove the cover from the fuel pump, remove the filter, clean and rinse it with clean fuel. Then be sure to blow out with compressed air;

- Check the condition of the filter. If it is deformed, no repair will help. You will have to change the filter device;

- If you have a Pekar pump or a similar one, the filter can be removed by unscrewing the suction fitting from the cover. That is, it is not necessary to remove the cover at all.

Pump diaphragm failure

A malfunction of the fuel pump diaphragm is indicated by traces of fuel leaks on the pump body and the presence of a fuel smell in the engine oil of your VAZ 2109 power unit. Just keep in mind that these signs do not always appear, although the diaphragm may be broken.

You need to do the following for your fuel pump:

- Remove the upper part of the fuel pump housing and remove the diaphragm assembly from there;

- Unscrew the nut on the rod, and then pull out the 3 diaphragms;

- Replace faulty elements with new ones. They are available in any repair kit for the VAZ 2109 fuel pump;

- Reassemble the assembly in reverse order;

- If you have a Pekar pump, there is only one diaphragm. It can be removed by removing the cover;

- To disconnect the diaphragm assembly, rotate it 90 degrees.

Be sure to simultaneously check the condition of the spring located under the diaphragm. To do this, you need to remove the upper part of the pump housing, remove the diaphragm rod and look at the current state of the spring. If it is broken, deformed or lacks elasticity, replace the element.

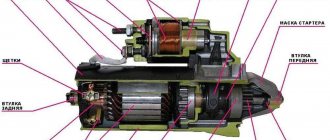

Node elements

Intake and exhaust valve malfunctions

If both valves raise doubts about their functionality, certain measures will have to be taken.

- Remove the cap from the fuel pump and remove the strainer.

- Visually assess the condition of the pump cavity and inlet valve.

- With the top of the pump body removed, you can take a look at the outlet valve.

- If both valves are not installed tightly enough, they are not pressed well or have become motionless, replace the entire pump completely.

- If you find traces of clogged valves, remove them and blow out the housing with compressed air.

In the case of the Pekar pump, two valves are located in the cover, so to assess their condition, simply remove the cover from the fuel pump housing.

Damage to the pusher

It is not uncommon for a fuel pump to fail to operate due to damage to the pusher. We have prepared separate instructions for this case.

- Remove the pump from the studs by unscrewing the fastening nuts. The thermal insulation insert, pusher and gaskets remain on the motor.

- Rotate the crankshaft to extend the pushrod as far as possible.

- Measure the distance that the pusher protrudes relative to the top gasket. Normally, the figure is 0.8-1.3 millimeters.

- If the protrusion is smaller or larger, try adjusting it using thicker or thinner shims.

- Between the thermal insulation insert and the pump there is an external gasket with the greatest thickness. It is this that needs to be changed when adjusting the protrusion.

- New gaskets are available in repair kits, although many make their own. To do this you will need a piece of paronite.

Fuel pump characteristics

In order to determine the presence of malfunctions in the fuel pump, you must know about the optimal parameters of this device.

| Characteristic | Required parameters |

| Fuel pump rod length | 82.4 millimeters |

| Protrusion of the rod above the top gasket | 0.8-1.3 millimeters |

| Thickness of the first gasket | 0.3 millimeters |

| Fuel pump rod stroke | 2.5-2.8 millimeters |

| Pump pressure at idle speed | 0.20-0.35 atmospheres |

Buying a new fuel pump will not cost that much - up to 1000 rubles. However, such costs are also high for many. And for some, their conscience simply will not allow them to buy a new pump right away, if it is possible to get by with a repair kit and return the pump to functionality for literally pennies and a couple of hours of work in your own garage.

Replacing the device

Disassembling and replacing the fuel pump

So, now we’ll tell you specifically about how to properly disassemble, replace damaged elements of the fuel pump, or completely replace this device with a new one.

Hatch

- In any case, we recommend purchasing a repair kit. It doesn't cost much. But there is no need to rush into buying a fuel pump. Who knows, maybe a simple repair will bring the pump back to life.

- Remove the air filter along with its housing.

- Disconnect the fuel supply and return hoses from the fuel pump fittings.

- Unscrew the mounting nuts that hold the pump itself.

- Carefully remove the pump, being careful not to damage the gaskets.

- Inspect the pump parts for cracks or damage. Check the fuel pump valves for leaks and perform all the operations we described above.

- Assess the current condition of the suction and discharge fittings. When dismantling, they must remain motionless in their seats. They break extremely rarely, but nothing should be ruled out.

- Check the fuel pump diaphragm. The presence of ruptures and peelings indicates that it must be replaced.

- Look at the current filter. Damage and excessive contamination are clear signs of wear and warrant replacement.

- Treat the filter components with clean gasoline and blow with compressed air using a compressor.

- If you find damaged elements, replace them with new ones using a repair kit.

- Replace the pump gaskets if necessary.

- When installing new gaskets, be sure to first treat their surface with Litol 24.

- If the pump housing itself is damaged or there are other serious problems, you will have to completely replace the fuel pump. Repairs won't help him.

- Next, when partial repairs are completed or you decide to take a completely new pump, it’s time for reassembly.

- Be sure to adjust the feed using shims of the required thickness so that the pusher output has an optimal indicator. We talked about this above.

- If the pushrod protrudes too much, it will cause the fuel pressure to be too high, causing your carburetor check valve to break.

- If the distance is less than required, as the load increases and the vehicle speed increases, the engine will not be able to receive enough fuel.

- Reassemble by following the reverse sequence of dismantling the fuel pump.

- Make sure the arrow on the body points towards the carburetor.

- When installing the diaphragm pump assembly, the holes in the gasket are located away from the muffler pipe.

Well, you figured out how you can repair and replace the fuel pump yourself. The task is really not difficult, although this unit plays a very important role in the performance of the entire VAZ 2109 car.

No Comments Yet! You can be first to comment this post! Close Window

Loading, Please Wait!

This may take a second or two.

Checking and adjusting pump pressure

It's no secret that any car part has a certain resource. So the “nine” fuel pump, like any part, eventually stops pumping gasoline properly, our instructions will help you figure it out:

- Moreover, on the VAZ 2109 the problems with the fuel pump are always the same

- As a rule, the reasons are not tightness of the valves or housing, fuel wire, or diaphragm, perhaps the fuel filters are clogged, or the fuel supply lines are overheating

- The main problem is ultimately insufficient gasoline pressure at the outlet of the fuel pump.

- And in the case when your fuel pump initially could not show the appropriate (required) output pressure, then all the problems stated above only aggravate the situation

- You need to know exactly the output pressure (immediately before the carburetor) that the fuel pump should develop when the engine is idling.

- As a rule, all fuel pumps - both cars and trucks - must produce a pressure in the range from 0.20 atmospheres to 0.35 atmospheres. When your gas pump has a similar output pressure, then you should not have problems with gasoline supply

- The pressure is measured with a pressure gauge that has a scale with divisions of 1.6 atmospheres - on such a pressure gauge it will be possible to record the pressure of the fuel pump

- When the pressure is measured and it turns out to be below normal, you may just need to adjust the pump

- It is possible to adjust the fuel pump either by moving it closer or further from the engine block (by changing the thickness of the gasket)

- The second method is to strengthen the spring (washers are placed under it, the operation is performed taking into account the wear of existing parts and the strength of the spring)

- The third option is to change the length of the rod

- Any of the listed measures (or all in combination) make it possible to increase the pressure of the fuel pump to the level of 0.20 - 0.30 atmospheres

- The best thing, of course, is to bring the figure to 0.30-0.35 atmospheres at idle speed

- When the engine starts running at higher speeds, this figure will increase a little more.

Characteristics of the VAZ 2109 fuel pump

To understand how a working pump works and check its operation, it is important to know its operating characteristics:

- The length of its rod is 82.4 millimeters

- In this case, the rod protrudes above the gasket by 0.8 - 1.3 millimeters

- The thickness of the very first gasket is 0.3 millimeters

- And, the stroke of the rod is 2.5 - 2.8 millimeters

Useful tips

A couple of very useful recommendations for beginners on what to do if a fuel pump malfunction occurs on a VAZ 2109:

- It is important to note that on machines with a return line, the problem may arise due to the release hole being too large, then most of the pressure is relieved by the return line

- If the installed pump on your machine cannot be adjusted, you will have to replace it

- Today, dozens of models of pumps for VAZ from different manufacturers are sold on the market.

- In order not to buy a fake, you should approach the purchase very responsibly - choose a branded store and a reputable manufacturer, purchase only fuel pump models recommended by the VAZ plant

- And the most ideal option is to contact an official VAZ spare parts dealer in your region, then you will receive the necessary part quickly, and you won’t worry about whether you got a bad quality fuel pump, and you won’t have to look for and buy a new pump a second time

Malfunctions of the electric gasoline pump

The VAZ 21099 is equipped at the factory with an electric submersible fuel pump. They are very different from their mechanical counterparts. These parts cannot be disassembled and therefore cannot be repaired.

Failure of these parts is mainly due to overheating or running on low-quality gasoline. The pressure drops, fuel does not enter the engine, and the engine does not start.

Quite often, such a malfunction is associated with electrical wiring. If the electric fuel pump hums loudly and fuel pumping has stopped, you must first check the condition of the wiring. The following problems may occur:

- Short circuit.

- The relay has failed.

- The fuse has blown.

If there are no problems with the electrical system, a new fuel filter must be installed. Sometimes it helps. If the result remains negative, you will have to replace the pump.

Correct procedure for disassembly and replacement

To remove the fuel pump, you need to perform the following sequence of actions:

- Buy a repair kit right away, its price is cheap

- Remove the air filter and its housing

- Disconnect the fuel supply and return hoses from the pump fittings

- Unscrew the nuts that secure it

- We remove it carefully, as there is a possibility of damaging the gaskets.

- Then you should inspect all the parts for cracks, check the tightness of all its valves

- Make sure that the discharge and suction fittings do not rotate in their sockets

- Diaphragms should not have peeling or ruptures

- The filter must be undamaged and absolutely clean

- Wash all its parts with gasoline and then blow them out with a compressor

- After checking, replace all damaged parts; it is recommended to change the pump gasket as well.

- When installing the gasket, apply lubricant like Litol-24 to its surface

- If the housing is damaged or the main parts are irreparably damaged, replace the pump completely

- Then you can proceed to installing it back

- In this case, immediately adjust the feed using shims

- And for this we measure the protrusion of the pusher

- Since with a strong protrusion, increased gasoline pressure will be pumped, which will easily break the carburetor shut-off valve

- In the case when the distance is lower than necessary, when the load increases and the vehicle speed increases, an insufficient amount of gasoline will flow into the carburetor

- The procedure for installing the pump is the reverse of removal.

- Also make sure that the arrow located on the body points towards the carburetor

- When installing the diaphragm unit, it is important to place the holes in its gasket away from the muffler pipe

Here we have outlined more detailed instructions for removing and disassembling the fuel pump to make it easier for you to do it yourself if a fuel pump malfunction occurs on your VAZ 21093. We conclude here, there should be no difficulties; in addition, you can, of course, watch a video lesson on this topic.

The fuel pump does not work, the relay turns on.

Checking relay power.

In the case when the fuel pump relay turns on when the ignition is turned on, but the pump itself does not work, you need to check the power at terminal 87 of the fuel pump relay. To do this, touch terminal 87 of the relay socket with the output of the control lamp connected to the vehicle ground, and the lamp should light up. If the lamp does not light, it means the fuse has blown or there is a break in the wire.

If there is power at terminal 87, you should remove the relay from the socket, and instead place a jumper between pins 87 and 30. In this case, if the pump and connecting wires are working properly, the pump should start working and if this happens, the relay should be changed. If the pump does not start working, then, without removing the jumper, you need to touch the power wire on the fuel pump with a test lamp connected to the vehicle ground.

Checking the fuel pump power circuit.

If a submersible pump is installed on the car as part of the fuel module, you need to remove the connecting connector and touch one of the thick wires. When you touch one of them, the indicator lamp should light up. If the lamp does not light up on any of the wires, then it is necessary to eliminate the break in the wire from the fuel pump relay to the module connector or the pump itself, if the pump is of a remote type. One of the reasons for the break may be the anti-theft blocking of an installed non-standard alarm system.

In the case when the test lamp lights up on one of the thick wires of the connector or one of the terminals of the remote pump, you need to connect these terminals with a test lamp to each other. In this case, the control lamp should light up. If the lamp does not light, it is necessary to eliminate a break or poor contact in the wire connecting the pump to the vehicle ground.

If, when checking the wires and relay for turning on the fuel pump, no malfunction is detected, the electric motor of the fuel pump or its connection to the module connector is faulty. It is not difficult to find the cause by removing the fuel pump module from the tank. If there is poor contact with the connector, melting of the plugs will be visible. If melting is not noticed, then to check the pump itself, you can connect it to the battery. It should be taken into account that operating a submersible pump without liquid will damage the pump. A faulty pump should be replaced.

The fuel pump for the VAZ 2108 2109 21099 is installed with an electric injector. That is, it is turned on by supplying +12V voltage from the battery to it. It is located in the gas tank of the car. The task of the fuel pump is to supply fuel under pressure into the fuel rail, from where it is sprayed directly into the working cylinder using the injection system. Checking the performance of the fuel pump VAZ 2108 2109 21099: 1) When the ignition is turned on, the pump should start working. That is, the sound of its operation should be heard in the rear seat area. Therefore, the very first thing you need to do is check the fuse and the fuel pump relay. The assignments of the relays and fuses are labeled on the back of the mounting block cover. If the fuse is intact and the relay is working properly, then you need to remove the back seat of the car and measure the voltage at the fuel pump itself. This is done using a multimeter or wires with a 12V light bulb.

Purpose and principle of operation of the fuel pump

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

Design and operation of fuel supply

The system that provides the engine with the required amount of gasoline operates according to the following algorithm:

Reference. In various car models, 2 schemes are used for installing the RTD and laying the return pipeline - in the engine compartment or directly in the gas tank. In the first case, the standard fuel pressure in the system is 2.7...3.0 Bar, in the second - 3.8...4 Bar.

A common mistake made by ignorant car enthusiasts: if the combustible mixture does not enter the cylinders, then the fuel pump is definitely not working. Knowing the design of the fuel supply, we can assume other problems:

To accurately determine the source of the problem, you need to check the operation of the electric fuel pump and other elements. It is not necessary to go to a service station - diagnostic work can be carried out in your own garage.