UAZ-Patriot | Topic author: Rhette

this patriot is an ASS and not a car. bought a new one. Fyodor (Basanti) Come on. If you don't like it, sell it! You bought Kaldina when she was already 12 years old. Everything in a hundred rows there had already been changed and rebuilt. Buy a new kmri now and then tell us how “magnificent” everything about it is. And here is a new UAZ and minor factory defects.

Sergey (Brigette) Don’t panic. Take care of the car. Then he’s testing you, whether you’re a friend or not.

Alexander (Aniteja) I hope so. although, they say, timing chains often break on patriots. it's an ass.

Sergey (Brigette) Became in good spirits and happiness will come.

Alexander (Aniteja) I’m also thinking of installing a two-row one at the nearest maintenance. It’s not clear why they don’t install it at the factory? (

Vitaly (Egil) Well, no luck with the car

Fyodor (Basanti) Don't worry. The target on my Patrick rattled at about 55 thousand miles, I replaced the chain at 70 thousand. I read on the Internet that it breaks sometimes, but no one I know has had this happen. The harbingers appear long before that. Hardly for no reason at all.

Sergey (Brigette) They save on everything, including lubricant, etc.

Alexander (Aniteja) Unsubscribe. when you drive it at least 150 thousand

Alexander (Aniteja) 2007, mileage 160 thousand. breakdowns everywhere and this is subject to driving on a normal road.

Alexander (Aniteja) Yes, all these are little things, no need to be sad!

Fedor (Basanti) Already passed, don’t worry. The drive belt rollers have been worn out for the last six months - one year before that they came across good ones. Well, once the thermostat jammed on a small circle in the heat, the cardan cross, the generator bearings stuck on me a couple of times, some other little things, but nothing major. Before the UAZ I had a Shevik, within two months (at 90,000 miles) it had a transfer case, RPM, clutch, radiator - I sold it and crossed myself. UAZ is better quality

Alexander (Aniteja) Then tell me honestly, I won’t believe that nothing broke.

Alexander (Aniteja) It was and still is a two-row one, it traveled 360 km with the teeth of the tension gear “eaten”, the speed was 100-120 km, under its own power for repairs.

Dmitry (Lilija) And the new single-row plate one runs for a long time, a friend has 105 thousand miles on it. But you immediately need to throw out the original tensioners, the whole reason for the breakdown, install ISAI and there is no need to go deep.

Dmitry (Lilija) UAZ is not an ass, it is a best friend with whom you will not get bored. Love him and he will turn his face to you and not his ass! Do it yourself!

ELENA (Aelianus) You need to love him like a child) and take care of him) and then he will be your best friend) at first I also tested me for everything. But I persevered. And now our love is mutual

Vladimir (Sangita) Guys, there’s no need to argue, so I want to buy Patrick and I don’t mind some little things, because I love the car like a woman and repair and drive it, if they start crying over such little things, it means the person hasn’t had his car repaired somewhere on a winter road somewhere -30-35 and there is no connection and only there you and the car. I myself work in the Urals on a TsA-320 and believe me, the little things that you described are nonsense. There is one understanding between the car and the driver, how you relate to it and how it relates to you .Believe me, it has been verified by my own experience. And by the way, Christ is Risen for everyone.

Divers (Rhette) Much of what is said and written is true. But! Don't forget that this is a Russian car, which means it's not for the faint-hearted! But overall the car is good, I'm happy with it!

Tags: How to remove a UAZ Patriot generator with air conditioning

Device and features

The plant equips cars with synchronous generators Iskra, Pramo Electro or BATE, equipped with a silicon rectifier unit and an automatic voltage corrector. A pulley is installed on the rotor shaft, which is secured with a key and a nut. Torque is transmitted from the engine crankshaft using a belt drive with a manual tension mechanism.

When adjusting, you should follow the manufacturer's recommendations, since excessive tension leads to premature failure of the bearing supports.

The diode rectifier unit is removable, which simplifies the equipment repair procedure. The straightening device is hermetically sealed, i.e., it is ensured that it remains operational when water enters. The rated output voltage is 14 V, the current does not exceed 80-90 A (on cars with air conditioning, the parameter is increased to 110-120 A).

The rotor is mounted on 2 ball bearings and rotates to the right (as viewed from the drive side). The external casing of the generator is made of aluminum alloy, and a fan is provided for cooling.

Diode bridge

A semiconductor diode bridge mounted on the outer part of the back cover of the electric generator is designed to convert alternating current into direct current. The design of the unit uses silicon diodes, which allow voltage to be conducted in only one direction.

To prevent short circuits, the parts are located in a sealed casing. During operation, the device is cooled by convection and air flow created by a fan mounted on the rotor.

Semiconductor diode bridge for UAZ Patriot.

Three-level regulator

The factory-assembled generator design uses a standard rectifier unit, which operates without taking into account the ambient temperature. As a result, there is a voltage drop and incomplete charging of the battery.

To increase the operating parameters of the electric generator, a modernized 3-level regulator is used. The device automatically adjusts the current parameters in the generator output circuit, focusing on the air temperature. The design includes a mechanical toggle switch to switch to winter operation mode.

Patriot vehicles do not charge the battery due to the alternator rotor speed decreasing when driving off-road (putting additional load on the electrical circuits).

The situation is corrected by replacing the pulley (to increase the rotor speed) or installing a more powerful generator produced by alternative suppliers. The use of a 3-level regulator allows you to improve the operation of the electric generator; installation of an additional device is carried out independently.

Installation of a three-level regulator

Algorithm for installing equipment on UAZ Patriot gasoline and diesel engines:

- Dismantle the generator, and then remove the protective casing located on the rear cover.

- Disconnect the standard voltage regulator and inspect the condition of the collector plates on the generator rotor.

- Install the upgraded unit into place, which is secured and connected with standard nuts and wires.

- Route the additional cable with corrugated protection through the additional hole in the protective cover.

- Install the control controller on the wall of the engine shield. Enable the operating mode appropriate for the operating conditions.

- Install the generator in its original place.

It should be borne in mind that the use of a 3-level regulator is not a panacea. It is not recommended to connect additional electrical devices to a vehicle with the engine running at idle speed.

To power external equipment, it is recommended to use portable gas generators equipped with rectifier units.

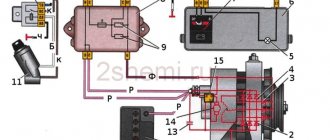

Connection diagram

The regulator body is connected to the car body, the plug with the letter Ш is used to connect to the modernized brush assembly. The second output from the brushes goes to the third contact B of the regulator. Block B is connected to the positive pole of the battery through a relay operating from the ignition switch.

A resistor is installed in the instrument panel so that the indicator does not show errors at idle speed.

Removing the generator

Algorithm for removing the generator from Patriot cars with a ZMZ 409 gasoline engine:

Step-by-step removal of the generator from a UAZ Patriot.

- Disconnect the negative cable from the battery.

- Disconnect the plug with cables connected to the field windings.

- Unscrew the nut securing the wire to the positive terminal of the electric generator.

- Loosen the tension roller by turning the roller mounting bolt, and then rotate the screw that reduces the tension of the belt drive.

- Remove the belt from the pulleys, and then unscrew the generator housing locking bolt.

- Unscrew the nut designed to secure the upper part of the device to the adapter bracket.

- By analogy, the lower attachment point is unscrewed and the fixing bolt is removed from the hole.

- Disconnect the bracket from the cylinder block (secured with 2 nuts) and dismantle the generator for repair or maintenance.

On cars with a 4CT90-1 diesel engine (Andoria), a single belt is used to drive the generator, rotating a fan pulley connected to the water pump rotor. Before dismantling the electric generator, you will need to remove the impeller, which prevents the removal of the belt and blocks access to the bolts.

Additionally, the air pipes are removed, blocking access to the generator. The generator housing is used to tension the belt, the adjusting bolt is located at the top, and an additional support is mounted at the bottom.

Why does the generator fail?

One of the reasons for generator failure is careless operation of the vehicle. An unpleasant sound that will come from the generator during a trip can warn of a breakdown.

Also, it is not the generator itself that may fail, but its constituent elements, and in this case, repairs alone can be sufficient. But if the situation is not corrected in time, the generator will break down and will need to be replaced.

To replace the generator, it is recommended to contact specialized service stations, where real professionals are ready to take on the work. They will conduct high-quality diagnostics, determine the cause and quickly repair the generator or install a new one. If necessary, you can replace it yourself. But for this you will need to familiarize yourself with how the UAZ Patriot works and the generator connection diagram. In addition, you can watch various photos or videos of similar processes.

Do-it-yourself replacement involves performing several steps.

Preparatory stage

In this case, the car owner needs to prepare the required tools, as well as buy a new generator - this can be the original model or its analogue. The tools you will need are:

- screwdrivers;

- wrenches for various diameters;

- extension;

- hammer.

After this, you can proceed to the next stage.

Main stage

The main stage of replacing a generator involves removing it and installing a new unit. The removal process is divided into several steps:

First, you will need to install the car in the repair site and take care of fixing its wheels. You will also need to turn off the engine and remove the terminals from the battery. This is necessary to ensure the safety of the work being carried out. Next, you need to disconnect the connectors with wires from the generator

This must be done as carefully as possible so as not to damage the wiring and the holes where the wires are attached. After this, you need to unscrew the nut from the negative terminal and remove the main cable connected to the generator

The fourth step is to remove the drive belt. To do this, you will first need to loosen the rollers to which the belt is attached, and then proceed directly to removing it.

The next step is to loosen the tension of the counter-bolt and nuts of the upper fastening

It is important to hold the generator at this time to make it easier to unscrew the fastening element.

The same is done with the bolts and nuts at the bottom of the generator.

Finally, the Patriot owner will only have to unscrew the two bolts securing the upper bracket and remove the generator. After this, you can either repair the failed unit, if during the inspection it turns out that this is possible, or install a new one.

Reinstalling the generator is done in exactly the same way as disassembling the structure, but you need to proceed in the reverse order

Therefore, it is important to mark bolts, nuts and other fasteners during work so that you can understand which element they are responsible for fixing.

Functionality check

When the assembly of the structure is completed, all that remains is to check the functionality of the new generator. To do this, you need to connect the terminals to the battery and start the engine.

The absence of any sound from the generator will indicate that the work was completed successfully and you can continue to operate the vehicle. The same work is carried out for UAZ "Patriot" with air conditioning.

To prevent such problems from arising too often in the future, and to avoid having to spend a lot of money on purchasing a new generator, it is recommended to regularly inspect the condition of the entire vehicle and carry out timely repairs of failed elements.

Source

Diode in the circuit

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Installing a diode with a toggle switch is the easiest way to increase the voltage. There is no need to bother, look for a lot of information in books, etc. Everything is as accessible as possible, no special difficulties.

This option of increasing the voltage, despite its simplicity, gives the most reliable result. Ideally suited for domestic and VAZ car models.

The purpose of this method of increasing the voltage in the vehicle's on-board network is to deceive the regulator, which is located inside the generator. As you know, on old domestic car models (kopek, VAZ 2105, etc.) the voltage drop sometimes reaches critical values - sometimes it drops to 12.5 volts. The battery, of course, will not be charged at this voltage.

A voltage regulator is the same brushes, a tablet, a chocolate bar - there are many names, but it is the same element that is responsible for regulating the voltage in the generator. On our domestic cars, mostly older ones, the tablets are of poor quality. They do not regulate voltage well, and as mentioned above, sometimes the current value drops below the baseboard.

So, what you need to do is insert an additional diode into the circuit. By this we will achieve the following: by how much the voltage on the diode is reduced, the regulator will increase the total current in the circuit.

There are several ways to integrate a diode. One of the best - remotely. Take a simple toggle switch and install it somewhere convenient.

Obviously, the toggle switch should be routed through the wire to the generator. You can insert the diode into the slot in the generator bridge, in the place where the wiring runs from the excitation winding to the regulator. That is, we simply insert the diode into the wiring between the bridge and the regulator.

We connect a separate toggle switch to the diode through two wires, as shown in the photo below.

When the voltage in the on-board network is sufficient, for example, in the summer, the diode is simply installed and not used. If the current is low, just turn on the toggle switch by activating the diode. In this way, we deceive the regulator.

The following diodes can be used.

Their analogues, for example, imported ones, are also suitable. They are much more compact, made of plastic (body). Domestic - metal.

Using a diode, you can provide a voltage drop of 0.9 or 1.2 volts. Thus, if the drawdown reaches 13-13.6, then approximately 1 volt will be added by the regulator. This is normal for winter loads. The standard drawdown of the regulator should be up to 13.8 volts, not lower. At this value, the battery can still charge, but if the voltage is lower, it won’t.

A drop in voltage below standard values for modern calcium batteries is especially critical. The fact is that low drawdown kills such batteries; they deteriorate. Naturally, an increased voltage indicator is not recommended. It should be no more than 14.6 volts (more about this in the table at the end of the article).

Installing a diode in a circuit is a universal solution that gives good results. However, there are some important points to keep in mind:

- Observe polarity when connecting an additional diode. If you break this rule, the battery will not be charged.

- The diode must be selected so as to deliver a current of at least 5 A.

- It is advisable to install the diode outside the generator, as it will get very hot.

- Silicon diodes are considered more efficient. They are capable of taking voltage within 0.8-1.2. But germanium diodes are no more than 0.7 volts.

How to choose a drive belt for an engine with air conditioning

> Questions and answers

16.12.2019

To select a belt for a UAZ Patriot 409 engine generator with air conditioning, you need to know the features of your car model. Cars of this brand may have 1 or 2 such components. The main parameter by which you need to select a new spare part is length.

Alternator belt characteristics

UAZ Patriot cars use engines with air conditioning of Euro-3 and Euro-4 models. They have a poly V-belt installed. It is a closed loop. On the inside of the product there are several longitudinal strips, also called rivulets or wedges. Due to this design, it got its name.

On the UAZ Patriot, spare parts with the numbers can be used for the generator:

- 6РК2120;

- 6RK2100;

- 6РК1275;

- 6РК1220.

This code contains all the parameters necessary for selecting a component part. The last 4 digits of the code indicate the length. The first number is the number of streams.

For example, a spare part with catalog number 6RK2120, used on a UAZ Patriot, has the following characteristics:

- length - 2120 mm;

- number of streams (wedges) - 6;

- product width - 21.4 mm;

- weight - 280 g.

Location of the element in the car structure

To quickly and correctly install a new belt, you need to have a diagram of how this spare part should go around the rollers and pulleys. A detailed image can be found in the vehicle's operating instructions. Owners of a car of this brand are recommended to always have with them not only a spare part, but also a visual explanation.

In the 409 engine with air conditioning, the alternator belt is positioned so that to remove it, you just need to press the tension rollers. No need to remove fan or diffuser

The old part can be pulled between them by carefully rotating

A new spare part is installed using the same scheme. In this case, you must first wrap the belt around all the rollers and only at the last stage put it on the generator.

How to choose the right drive belt

First of all, you need to decide on the required length. Starting from 2012, when the Patriot was equipped with a Euro 4 engine, a model with a length of 2120 mm was used.

On cars manufactured between 2007 and 2012, a belt with a length of 2100 mm was initially installed. When replacing a failed spare part, it is permissible to choose a longer length. Experienced car enthusiasts claim that in this case the installation process will be much simpler. However, one may come across the opinion that a longer component part will begin to “whistle” much earlier.

Also in models released between 2007 and 2012. You can find engines that have 2 belts installed. In this case, depending on the modification, components with the number are used:

Therefore, before buying a new belt, you need to open the hood or technical documentation for the car in order to find out which engine version is installed

One of the key points is the material from which the belt is made. If a manufacturer used cheap waste from the production of rubber products, then its products will not last long. This material hardens in the cold and becomes “oak”. This leads to cracks appearing on the surface.

To ensure that the belt does not crumble and lasts a long time, it must be made of EPDM. This is a generalized international name for materials manufactured using ethylene-propylene rubbers. This spare part is resistant to aging and temperature changes.

Therefore, it is most often recommended to give preference to products from European or Asian manufacturers.

Manufacturers of spare parts

As a replacement for the original belt installed at the factory, any analogue that matches in length and width can be used for a UAZ Patriot. Such products can be found from companies:

- SKF;

- Gates;

- Globelt;

- Bosch;

- TANAKI Co. Ltd;

- LYNXauto.

Poly V-belts of this configuration are used in car engines of such brands as Ford, Lexus, Opel, etc. Therefore, choosing a quality spare part is quite simple.

Experienced auto mechanics do not recommend purchasing components produced by companies such as Luzar or Zommer, despite their lower cost.

How to choose a drive belt for an engine with air conditioning Link to main publication

see also

Comments 58

Try dubbing + and - from the generator to the Akum cable kg -35. Personally, it helped me so much, there was no drawdown

Yes, I plan to do this... I just recently got the car, not all at once

Try dubbing + and - from the generator to the Akum cable kg -35. Personally, it helped me so much, there was no drawdown

the generator should have been installed immediately

I read somewhere that the life of a conventional generator is limited by the life of the brushes and copper rings on the rotor. And the resource of the brushless gene is limited by the resource of the bearings, and this (I don’t remember the numbers) is an order of magnitude greater. Examples of installations WITHOUT BRUSH generators on UAZ engines. The idea is clear, moving the bracket into place will not be difficult.

It was necessary to immediately install a normal launch vehicle, such as Cargo.

But don’t tell me it didn’t help me, I probably got a defect, replaced the diode bridge and put in a regular tablet and everything was fine

It was necessary to immediately install a normal launch vehicle, such as Cargo.

the generator should have been installed immediately

I read somewhere that the life of a conventional generator is limited by the life of the brushes and copper rings on the rotor. And the resource of the brushless gene is limited by the resource of the bearings, and this (I don’t remember the numbers) is an order of magnitude greater. Examples of installations WITHOUT BRUSH generators on UAZ engines. The idea is clear, moving the bracket into place will not be difficult.

RN is much cheaper than genes

FROM THE FACTORY I HAVE A BELARUSIAN GENA WITHOUT LOAD 14.4 A WITH LOAD 13.5. ON WORKING GAZELLE 14.5, REGARDLESS OF LOAD (CUMMINS)

There is one nuance, on a Patrick with a condenser, it’s difficult to install the generators from a gazelle

IT'S ME WHO MUCH WHAT IMP. GENES DON'T SHAK OUT

Yes, I know, I’ve been tinkering with foreign cars for about 10 years now

There is one nuance, on a Patrick with a condenser, it’s difficult to install the generators from a gazelle

I had a 100A from a Gazelle with an air conditioner, everything is fine

FROM THE FACTORY I HAVE A BELARUSIAN GENA WITHOUT LOAD 14.4 A WITH LOAD 13.5. ON WORKING GAZELLE 14.5, REGARDLESS OF LOAD (CUMMINS)

the generator should have been installed immediately

I read somewhere that the life of a conventional generator is limited by the life of the brushes and copper rings on the rotor. And the resource of the brushless gene is limited by the resource of the bearings, and this (I don’t remember the numbers) is an order of magnitude greater. Examples of installations WITHOUT BRUSH generators on UAZ engines. The idea is clear, moving the bracket into place will not be difficult.

For myself, I chose the gene option suggested by SergeiSmile. He has a blog entry about a Volga generator. Its performance characteristics are such that, unlike the UAZ, it produces more than half the power at low speeds, which allows you to use devices without a strong voltage drop; modern calcium batteries also do not suffer from undercharging. It's not expensive, but it's clear that it's well made. It is also visually clear why it has better performance characteristics. In the place where the windings are located, the diameter of the genes is clearly larger than the stock one. The contact bolt is M8, not M6. That is, everything suggests that it was originally designed for greater productivity. It is surprising that products for GAZ are often better and more thoughtful than for UAZ, although for Patra, the need for safety margins and other things is initially higher in terms of tasks. It is also a huge plus that in this gene you can install a modern, integral, multifunctional LV type 844.3702, 845.3702 and the “orbit” analogue, which allow gentle starting of the generator and produce a higher voltage relative to the original LV. This LV also allows you to take voltage readings directly from the battery, which allows you to equalize the voltage directly across the battery. Moreover, unlike the stock gene, where you have to remove the diodes from the bridge, in this gene there is no need to do this. It already implements an additional contact for this LV. I have implemented a remote pH, which also allows me to output voltage more consistently in the upper range.

Replacing the diode bridge on a UAZ Patriot

The problem with the low voltage of the electric generator may be hidden in an incorrectly functioning silicon bridge.

To check the functionality of the generator, you will have to completely disassemble the diode bridge and remove the spare part.

Ringing will help determine whether the bridge is in good condition or not. The rectifier bridge consists of six diodes conducting voltage in one direction. When ringing, we find out the resistance value. If the resistance differs between the diodes by more than 5 ohms, then it is necessary to replace the silicon bridge, since the difference in resistance will greatly affect the flow of current.

When purchasing a new diode bridge, the choice must be made based on resistance tolerances, otherwise problems with the electric generator will not disappear.

Generator for UAZ Patriot

Any car owner knows that a generator is a special electrical unit through which mechanical energy is converted into electrical energy. This device provides electricity to a huge number of devices, systems and elements in the car.

In the UAZ Patriot with a 409 engine, the manufacturer installed an Iskra 120A generator. The design of this device contains a current rectifier made of durable silicon. There is also a voltage relay built into the generator. Thanks to the presence of both elements, it is possible to maintain the voltage value in the required values set by the manufacturer.

The cost of the original generator ranges from 5,000 to 8,000 rubles, and the final price depends on the store that sells it. If necessary, for example, during replacement, you can install an analogue generator that will fit on the Patriot.

The table shows the popular models of generators used with their articles and prices.

| Generator | vendor code | Cost, in rubles |

| UAZ, GAZ engine UMZ-417.10, ZMZ-511 14V/40A G250P2.3701-03 (OJSC ZiT) | G250P2-3701000-P2 | 3790 |

| UAZ "Patriot" engine ZMZ 409.10 120A 5122.3771-30 (PRAMO) | 5122-3771-30 | 5170 |

| GAZ, UAZ engine ZMZ-405, -406, -409 14V/90A 9422.3701 (JSC ZiT) | 9422-3701000 | 3820 |

If necessary, you can buy a cheap analog and save on replacement.

Video “Visual instructions for dismantling the generator and lubrication”

You can learn more about how to disassemble the unit at home and how, and most importantly, how to lubricate the bearing, from the instructions given in the video below (author - Sergey Rotanov (RSV)).

The generator bearings whistled, and when turning the pulley, the unevenness of rotation was clearly felt. Before that, at a mileage of about 40 thousand km, I foolishly changed the bearings - the roller whistled, and I immediately attacked the generator, installed KOYO bearings, but before installing them, I opened them and added lubricant, which is STRICTLY NOT supposed to be done! As a result, the boot was squeezed out and it spun somehow separately from the bearing

For use in generators, bearings that are sealed on both sides are required; the index 2RS is added to their number, plus the index C3 or CM (radial clearance greater than normal or normal radial clearance). To repair the Pramo 5122.3771-30 generator, bearings 6303 (front) and 6202 (rear) are needed, I ordered KOYO again, but I didn’t open them

Generator bearing

The generator rotor is mounted on 2 ball bearings located in the end caps. The bearings are equipped with protective washers to prevent dirt from entering the treadmills and to retain lubricant. When the elements wear out, the rotor wobbles and noise occurs during rotation.

To carry out repairs, the electric machine is removed from the motor and then disassembled. Worn bearings are pulled together with a screw puller. New parts are pressed in using mandrels; it is recommended to check the amount of lubricant under the protective covers.

Rolling bearings used in components and assemblies of UAZ Patriot / UAZ 3163 vehicles since 2005

Typically, users of our site find this page by the following queries: UAZ Patriot chassis repair, UAZ Patriot chassis, UAZ Patriot front suspension, UAZ Patriot rear suspension, UAZ Patriot front suspension repair, UAZ Patriot rear suspension repair, UAZ 3163 chassis repair , UAZ 3163 chassis, UAZ 3163 front suspension, UAZ 3163 rear suspension, UAZ 3163 front suspension repair, UAZ 3163 rear suspension repair

Rolling bearings used in components and assemblies of automobiles

Bearings of the ZMZ-409 engine

| Bearing name | Designation | Quantity, pcs | |

| Combined special water pump | 406.1307027 (6-5НР17124ЭС30 1) or 406.1307027-01 (5HP17124E.P6Q6 1) | 1 | |

| Toe of the gearbox input shaft (in the flywheel) | — single-row radial ball with two protective washers or | 402.1701031 (6203ZZ.P6Q6/УC9 1) | 1 |

| — single-row radial ball with double-sided seal | 402.1701031-01 (6203.2RS.P6Q6/УC9 1) or 402.1701031-02 (6203.2RS2.P63Q6/У.C30 1) | 1 | |

| Automatic belt tensioning mechanism complete with roller and bearing | 40624.1029010 (0386 1 “Litens”) | 1 | |

| Front cylinder head cover assembly with special combined fan support bearing | 40904.1003083-01 | 1 | |

| The drive belt guide roller assembled with an angular contact double-row bearing with a double-sided seal² | 406.1308080-23 (256801 E.P6Q6/W61 1) | 2 |

1 Designation at the manufacturer

2 Applicable for engine configurations with installation of an air conditioning compressor

Meet UAZ 452

The car was a cargo-passenger version of an off-road vehicle with a 4x4 wheel arrangement. The Ulyanovsk Automobile Plant mastered production of the model back in 1965.

You can evaluate its capabilities by watching the following video:

The UAZ 452 is capable of transporting cargo weighing up to 700 kg in the back. In addition, it can tow a trailer weighing 850 kg. The vehicle became very popular not only in Russian off-road conditions, but was also successfully used in large cities in various capacities (pictured in the article).

In particular:

- Like a traffic police car;

- As a fire engine;

- Ambulance car;

- Grocery store;

- Utility vehicle, etc.

Electronic components

The electrical wiring of the UAZ 452 was a simple single-wire circuit.

Structurally, it had the following solutions:

- The role of the second wire was played by the metal body and the components and assemblies attached to it;

- All electronic components and actuators had a “-” displayed on the housing. The cost of such a solution justified the imperfection of the scheme.

For reference: The instructions provided for regular checking of contacts. When oxidized, they should have been cleaned with sandpaper.

Power unit

The engine compartment is located directly inside the car, as this is due to its design.

Access to components and assemblies is also provided from the passenger compartment by removing the cover, which:

- Provided protection for the driver and passengers from the penetration of exhaust gases;

- Protected from dust and dirt;

- Served as an additional heating element (passive - from heating).

The previously used engine from Pobeda was replaced with a more modern engine from the 21st Volga. This was facilitated by the launch of a production line at the Zavolzhsky Motor Plant in 1964.

Note! Despite some skepticism regarding the inconvenience of servicing a cabover car with your own hands, years of operation have proven that there are no difficulties.

Passive vehicle safety

The design of the "Baton" with a cabover layout also initially raised a number of questions regarding safety. However, a series of crash tests conducted back in 1971 at the Dmitrov test site proved that in most emergency situations the driver and passengers of the UAZ 452 have a chance to avoid injury.

How to check the voltage of the electric generator on the battery

Electromotive force or potential difference can be determined by the following methods - using generating equipment and through a battery. The electric generator is directly connected to the power source with a thick cable, so to check the level of potential difference, you can measure the voltage at the power source. When using this method, you will need special measuring instruments - a voltmeter, multimeter or load fork.

The device wires are connected to the battery in any order. The plug must be connected to the battery terminals, and the polarity must be strictly observed. The permissible voltage in the network should not be less than 12.5 volts. At idle speed with the electrical devices of the machine turned off, this figure should be about 13.5-14 V. Reducing the voltage values to 13.3-13.8 volts is acceptable.

Based on the above, the main types of failures of the UAZ Patriot electric generator can be problems with the poly V-belt, bearing failure, or failure of the diode silicon bridge. You can also solve the problem of voltage drop on the UAZ Patriot generator by installing a three-way regulator, but this will not solve all the existing problems. If problems are detected in the operation of the electric generator, it is necessary to immediately begin diagnosing it to identify the causes of the breakdown.

Video - Do-it-yourself diagnostics and repair of generators

Diode bridge faults

The diode bridge is also a weak point of the generator and its repair or replacement is carried out on a removed and disassembled car generator.

Before carrying out repairs, it is necessary to carefully inspect the part. Most likely, the contacts from the semiconductor elements were simply unsoldered on it. In this case, they are simply soldered into place and all the parts are installed back. Another thing is when burnt marks appeared on the surface of many diodes. In this case, it is best to replace the entire bridge and install a new element on the generator stator.

It is worth saying something about the features of diodes. These elements are designed to rectify voltage and have conductivity in one direction only. If this conductivity is broken, it means that the semiconductor is faulty and requires replacement. It is impossible to detect this by external examination, but there is the following way:

Using a lamp tester, check the conductivity of all bridge diodes. To do this, one contact of the tester is applied to one side of the diode, the other to the other. If the lamp does not light, then swap the contacts. Only in one of the positions should the lamp light up and this applies to all other diodes. If the lamp does not light up at all, or lights up in both directions, then the diode needs to be replaced. It is unsoldered, squeezed out, a new one is installed in its place and the contacts are soldered.

Other malfunctions. These may include disruption of various contact connections. In this case, the contact surfaces are cleaned or the entire contact is replaced. It is worth recalling that poor contact, at least in one place, leads to a decrease in the efficiency of the power supply or failure of the entire unit.

It's worth returning to the alternator belt again. Even if it is tensioned normally, feel it for moisture. It is possible that oil or antifreeze has dripped onto it, and it simply slips, disrupting the normal transmission of torque to the generator pulley. This also happens.

Separately, one can note the increased noise when the generator is running. The culprit for this noise is most often the rotor shaft bearing. Its noise indicates that it has worn out and needs urgent replacement. It is highly not recommended to delay this matter. The fact is that imbalance of the shaft will lead to contact of the rotor with the active steel of the stator, a short circuit will appear, which will also affect the voltage level of the on-board network.

This problem can be fixed. To do this, the generator is disassembled, the rotor is removed along with the bearing, which is then pressed out of the rotor. After this, a new bearing is mounted using special equipment, and the rotor is installed in its place.

This is all that is associated with generator malfunctions. If after eliminating the above the problem does not disappear, then you need to look for it elsewhere.