Any extraneous noise in a car engine often makes owners feel wary. And even if these sounds do not affect driving performance in any way, their very appearance makes the driver think about diagnostics. Many cars have knocking pins when accelerating, but this problem is often ignored. The sound appears when the car picks up speed. If you do not pay attention to this in time, much more serious problems arise. At the same time, car enthusiasts cannot determine the reasons for the appearance of knocking noises, nor can they fix this problem on their own. Let's look at the reasons for these sounds that are unpleasant to the driver's ear, and also find out how to fix these problems with the engine.

Knocking fingers

A ringing metallic sound may be heard from an engine that is running under load. They disappear when reaching a certain speed. Old school mechanics will say it's the "fingers" chattering during acceleration. However, the driver will be surprised, and he will be completely right: the sound has nothing to do with the “fingers” installed in the pistons.

Causes of sensor malfunction and ways to check it

The knock sensor on cars rarely fails, including the Priora. However, VAZ-2170 owners can often detect a DD malfunction error. And the reasons for its occurrence may be the following factors:

- Damage to the wiring that connects the sensor to the ECU.

During operation of the car, damage to the insulation may occur, which will ultimately affect the signal level. A normally operating sensor produces a signal from 0.6 to 1.2V. - Oxidation of contacts.

The device is located on the cylinder block and is exposed not only to moisture, but also to aggressive substances in the form of engine oil. Although the sensor contact is sealed, a connection failure cannot be ruled out, which leads to oxidation of the contacts in the sensor or chip. If the wire on the DD is in good condition, then you need to make sure that the contacts in the chip and on the sensor connector are intact. - Violation of the integrity of the body. It should not have cracks or other defects.

- Damage to internal elements.

This happens extremely rarely, and you can verify the suitability of the device by testing. The piezoceramic element or resistor may fail. To do this, you will need to perform a sensor test. - The connection between the sensor and the cylinder head is not reliable enough.

It is recommended to pay attention to this point to all owners of Priora cars whose BC displays error P0326 . The device is fixed with a bolt that has a shortened thread. This thread does not rest against the block with its end part, therefore vibrations from the block with a normally operating motor are not enough to generate the minimum permissible signal of 0.6V. As a rule, a sensor fixed with such a bolt produces a low voltage of 0.3-0.5V, which is why error P0326 occurs. The problem can be corrected by replacing the bolt with a stud of the appropriate size.

Having considered the main symptoms of a malfunction of the knock sensor on a Priora, you should resort to checking its serviceability. To do this, you need to arm yourself with a multimeter. The method for checking the device is quite simple, and it is much more difficult to remove the sensor from the car than to check its suitability. The check is performed as follows:

- Vehicle-mounted sensor. You can check the device without removing it, which is especially important for Priora cars with 16-valve engines, where access to the device is limited. To check the sensor, you must perform the following steps: get close to the sensor in order to be able to strike on or near it. We ask the assistant to start the engine, after which we strike the sensor with a metal object. As a result, the sound of the engine should change, which indicates that the ECU has set the ignition later. If such changes can be traced, it means that the device is working properly and is suitable for use. This also indicates that the sensor circuit is working properly.

- Checking the voltage on the sensor removed from the car. Connect the multimeter probes to its terminals and switch the device to the 200 mV voltage measurement mode. This is necessary in order to fix the voltage on the device. Next, lightly hit the metal part of the sensor with a steel object (or press the metal part with your fingers), and observe the readings. Their changes indicate the suitability of the device.

- Checking resistance. A working DD on Priora and other VAZ models has a resistance that is equal to infinity, which is quite normal, since when not working the piezoelements are not connected to the contact washers. We connect the device to the DD terminals, setting the measurement mode to MOhm, and take measurements. In the non-working position, the value will tend to infinity (on device 1), and if you start to influence the sensor, squeezing it or hitting it with a metal key, the resistance will change and amount to 1-6 MOhm. It is important to understand that sensors for other cars have different resistance values.

- Check the condition of the wires and contacts of the chip. It is checked visually, and if damage to the insulation is detected, the chip must be replaced.

- Checking the integrity of the circuit. To do this, you need to arm yourself with a multimeter with a continuity mode, and test the wires from the chip to the terminals on the ECU. The pinout diagram for the knock sensor on the Priora will help with this.

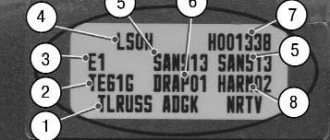

Knock sensor pinout diagram

The above presented pinout diagram for the Priora knock sensor is appropriate for January and Bosch brand controllers. If the wires are not damaged, and error P0325 is displayed on the BC, then this indicates a failure of the resistor. Some craftsmen eliminate such a breakdown by soldering a resistor of the appropriate size between the wires in front of the chip. However, this is not recommended, and it is much easier and more reliable to buy a new sensor and replace it. Moreover, the cost of the product is 250-800 rubles (depending on the manufacturer).

This is interesting! If checking the sensor and wires shows that there are no defects, but the error message on the BC about a device malfunction continues to light up, then you should resort to replacing the fastening element, that is, replace the bolt with a stud with an extended thread. How to do this correctly, read in the next section.

Why "fingers"?

The combustion process of the combustible mixture in a fully operational engine proceeds sequentially. A flame flares up near the spark plug, and gradually it fills the entire cylinder. But there is another combustion option - detonation. The explosion of the fuel mixture in the combustion chamber occurs abruptly. This increases pressure and temperature. This very explosion is called detonation. That's why the driver hears a knock - it comes from the blast wave. Proper combustion implies a fire propagation speed of up to 30 m/s. The gas pressure increases gradually. With this type of combustion, the flame fills the cylinder gradually. The gases press gently on the piston. There is no knocking of gas against the walls of the combustion chambers, since there is no explosion. If the burning rate is higher, then these are the prerequisites for detonation. By the way, this phenomenon is very harmful to the engine.

6A13. Detonation on a hot engine in the heat.

Moderators: mek, indy

6A13. Detonation on a hot engine in the heat.

#1 Post by Alex432 » June 17, 2012, 08:37

200,000. About a month ago, in hot weather (+30), after the engine had fully warmed up, the following began to happen. When driving in 2nd, 3rd, 4th gears with rpm in the range of 1500 - 3000, with strong (but not to the floor) pressure on the gas pedal, characteristic detonation knocks appear. They don't go away until you release your pressure on the pedal. When cold, everything is fine. At the same time, it became unusual for the engine to start after a day's parking (albeit the first time): before it cheerfully picked up with half a turn, but started with 3-4 turns and was somehow reluctant. Gasoline - 95. I've been filling up at the same gas station for about 4 years now. But lately, evil suspicions have begun to arise about it, and not only from me. Changed the gas station. I have already refueled 4 times from 15 liters to a full tank. Now the picture is as follows. In hot weather (+30) after the engine has completely warmed up, when driving in 2nd, 3rd, 4th gears with rpm in the range of 1500 - 3000, when you press the floor, there seems to be no detonation (at least I didn’t hear it), with a strong, but not in floor, pressed - short-term detonation (

Detonation - what is it?

If the “fingers” knock during acceleration, this indicates detonation in the engine. This is the name given to an instantaneous and very destructive in its force explosion of any flammable substance after an impact or activation of a detonator. This is the definition according to Ushakov’s dictionary. Detonation of flammable substances for car engines is the rapid burning out of a mixture of gasoline and air. Occurs when the engine operates under load at low speeds and low-quality fuel. This process is accompanied by knocking, vibration, and increased temperature. As a result, the “fingers” knock during acceleration (including the VAZ-2112).

Types of knock sensors: design features and operating principles

On fuel-injected cars, it is impossible to manually set the ignition timing, since electronics are responsible for this process. The appropriate amount of advance depends on various factors. The ECU collects information from all sensors, and based on their readings, as well as the operating mode of the internal combustion engine, it adjusts the SOP and the composition of the fuel assembly.

To prevent a prolonged detonation process, a sensor is used. It sends a corresponding signal to the computer, as a result of which the latter has the ability to adjust the ignition timing. We will find out further what signal the device sends to the ECU, and how it detects unstable operation of the internal combustion engine.

Before you understand the peculiarities of the operation of the DD, it is necessary to inform you that such devices come in two versions:

- resonant or frequency;

- broadband or piezoceramic.

Priora cars are equipped with broadband knock sensors.

The principle of their operation is based on the piezoelectric effect. Its essence is that when the plates are compressed, an electrical impulse is formed. Below is a diagram of the operation of the broadband sensor.

The operating principle of such a device is as follows:

- When the engine is running, the sensor generates a signal with a certain frequency and amplitude, which is recorded by the ECU. Based on this signal, the controller understands that the sensor is functioning properly.

- When detonation occurs, the engine begins to vibrate and “clatter,” which leads to an increase in the amplitude and frequency of vibrations.

- Under the influence of vibrations and third-party sounds, a voltage is induced on the piezoelectric sensitive element, which is transmitted to the ECU block.

- Based on the received signal, the controller understands that the engine is operating abnormally, so a signal is sent to the ignition coil, as a result of which the ignition timing changes towards the advance (a later ignition is set) in order to prevent the development of a dangerous detonation process.

The photo below shows examples of broadband and resonant type sensors.

The broadband sensor has the shape of a washer with a central hole and output contacts through which the device is connected to the ECU. Inside the housing there is an inertial mass (weight), insulators in the form of contact washers, a piezoceramic element and a control resistor. The system works as follows:

- when the engine detonates, the inertial mass begins to affect the piezoceramic element;

- the voltage on the piezoelectric element increases (on Priora up to 0.6-1.2V), which is supplied to the connector through contact washers and transmitted via wire to the computer;

- Between the contacts in the connector there is a control resistor, the main purpose of which is to prevent the controller from detecting an open circuit after the ignition is turned on (this resistor is also called an open circuit recorder). If it fails, then error P0325 is displayed on the BC.

The photo below describes the operating principle of resonant type sensors. Such devices are used on cars, for example, Toyota.

Determining the type of knock sensor that is installed on a car is not difficult. To do this, you need to inspect the part, and by its appearance you can understand the type of device. If broadband elements have the shape of a tablet, then frequency-type products are characterized by the shape of a barrel. The photo below shows a frequency-type sensor and its device.

This is interesting! Prioras are equipped with broadband sensors that have code 18.3855. Products are produced by different manufacturers, for example, AvtoKom, Bosch, AvtoElektronika and AvtoTrade (Kaluga plant). The cost of a Bosch sensor differs from other analogues by approximately 2-3 times.

Typical causes of ringing “fingers” during normal operation of the internal combustion engine

If the “fingers” knock during acceleration in the Kalina, the mass air flow sensor may have failed. If it is not working correctly, then the ECU will receive incorrect information and issue incorrect commands. Another reason is an incorrectly set ignition timing. For this reason, the point at which the fuel will burn maximum is approaching TDC. This leads to increased pressure in the combustion chamber. If the “fingers” knock when accelerating on a Ford Focus, then the knock damping sensor may have failed. It's definitely worth checking this item. If it stops working, it should be replaced.

Symptoms of a problem

It is quite difficult to immediately determine the failure of the motor control; you need to feel and know your car well in order to quickly feel the malfunction. The “Check Engiene” warning light does not light up in the event of a malfunction, but an error with the name “Low signal level of the knock sensor” is stored in the ECU; this error is numbered 0327.

Symptoms:

- Increased fuel consumption is quite difficult to notice quickly;

- Increased engine vibrations;

- More sluggish and longer acceleration of the car;

Why does detonation occur in engine cylinders?

Experts identify several main reasons why fuel detonates in the engine.

- First of all, it is worth immediately highlighting the use of low-octane gasoline in units with a high compression ratio. Simply put, the octane number of gasoline (AI-92, 95 or 98) actually indicates its resistance to detonation, and not its quality, as many people mistakenly believe.

The use of fuel with an inappropriate octane number for a particular engine naturally leads to the fact that the fuel-air charge detonates under strong compression. Let us also add that simple engines that do not have an ECM and a knock sensor are at greater risk.

- Engine coking. It is important to understand that modern engines not only in foreign cars, but also in domestic cars are very different from their analogues from the times of the USSR. In a nutshell, if the engines on the Moskvich 2141 model had a compression ratio of about 7 units and worked normally on any fuel, today the units have from 9 to 11 or more units.

- Violation of the mixture formation process. In this case, a too “rich” mixture, in which there is a lot of fuel in relation to the amount of air, may begin to detonate.

Note that such detonation can be short-term and often goes unnoticed by the driver, however, it is impossible to say that there is no harm to the engine.

- Ignition timing (IDA). In simple words, the ignition angle determines at what point the spark will be supplied to the combustion chamber. If we consider that normally fuel does not explode, but burns, then it becomes clear that the combustion process also takes some time.

In this case, it is important to ensure that the maximum gas pressure on the piston, which is formed as a result of the combustion of a portion of fuel, occurs precisely at the moment of the working stroke of the piston. This is the only way to effectively transfer the energy of the expanding gases through the piston to the crankshaft.

To do this, the spark can be applied a little earlier than the moment the piston reaches top dead center (TDC). During this time, the fuel will have time to ignite, and the expansion of gases and an increase in pressure on the piston will occur just at the moment when the piston has already reached TDC and then goes down.

- Design features of the combustion chamber. It happens that some engines are initially prone to detonation. In some cases, the reason is the design of the combustion chamber itself, the implementation of its cooling, etc.

Another culprit may be pistons that have an unsatisfactory thermal balance (for example, the piston bottom is thickened closer to the center, which noticeably worsens the quality of excess heat removal). One way or another, the risk of detonation on such engines is much higher.

- Engine overheating. If you pay attention to the previous point, it becomes clear that an increase in temperature in the combustion chamber is the cause of detonation. It is quite obvious that a decrease in the efficiency of the cooling system can lead to the engine overheating.

Where to look and how to check the knock sensor

In order to check it, you also need to know where the VAZ-2110 knock sensor is located. Everything is simple here; so that it can effectively capture vibrations, it is placed on the cylinder block. Its location largely depends on the design features of the motor itself.

On 8-valve engines it is usually located in the line of sight and is usually easy to get to. Therefore, it is not difficult to determine where the knock sensor is located on a VAZ-2107 (injector). It is installed on the exhaust manifold side and consists of a massive washer with wiring going to it and secured to the engine with a bolt.

But on 16-valve engines, the installation location is slightly different than the location of the knock sensor on the VAZ-2107 (injector). Due to the fact that the block head is much more massive, the sensor is located lower - under the exhaust manifold, so access to it is limited, and often it can only be reached from under the car on an overpass or inspection hole.

And although the location of the motor may differ slightly due to the design of the motor, its connection is always identical. Thus, the connection diagram for the VAZ-2109 knock sensor with an injection engine is the same as on the 2114 model.

Checking the VAZ-2110 knock sensor can be done in two ways.

The first of them implies the presence of a tester switched to measuring resistance (measurement level - up to 2 kOhm).

Checking the knock sensor with a tester

To check, you just need to disconnect the wiring block from the sensor and connect a tester to the sensor contacts. Then you should apply light blows with a wrench to the DD fastening bolt and monitor the readings on the tester display.

After connection, the display will show a certain resistance value of the sensor. At the moment of impact on the bolt, the resistance will increase sharply, but then return to the old value. If this does not happen (the resistance does not rise or does not return), the sensor is faulty and requires replacement.

The second method does not require any equipment and is more effective.

To carry it out, you need to start the engine and set the speed to 2000 rpm. Then take an open-end wrench, you can use a small hammer with a metal attachment (if access to the DD is limited) and strike the fastening bolt. If the DD is in good working order, after the impact, the engine speed should drop, since such an impact will be regarded by the sensor as detonation and the ECU, based on its signals, will reduce the ignition angle. After the impact on the bolt stops, the speed should be restored. If this does not happen, the DD is faulty.

How to eliminate engine detonation

So, having considered the main causes of engine detonation and having understood what it is, we can move on to how to get rid of this phenomenon. Let's start with old internal combustion engines. At the very beginning, you should exclude overheating of the engine, as well as refueling with low-quality or unsuitable fuel, and check the spark plugs.

The solution is temporary, since you cannot drive for a long time with a reduced ignition angle (the exhaust valves will burn out as a result of an increase in the temperature of the exhaust gases), but getting to the service center on your own is quite possible.

However, while driving, you need to constantly ensure that there is no characteristic “ringing” in the engine. You can also install a so-called electronic octane corrector on an old internal combustion engine to avoid manipulations with the distributor. Let us also add that, as practice shows, many owners of carburetor cars prefer to install electronic ignition.

As for more modern engines, injection units are equipped with standard solutions to avoid or minimize the risk of detonation. We are talking about an engine knock sensor (DE), which detects its occurrence. Then the corresponding signal is sent to the ECU.

Then the control unit independently adjusts the ignition timing taking into account the data received from the DD. Moreover, the possibility of such adjustment is, on average, an angle shift of 2 – 5 degrees. If it is not possible to get rid of detonation in this way, the ECU records the error and writes it to its memory, a “check” may light up on the instrument panel, the engine goes into emergency mode, etc.

It becomes clear that in this case, the driver at the initial stage needs to start by checking the knock sensor, and also read errors from the ECU memory. This can be done as part of computer engine diagnostics. You can also perform the check yourself (if you have a special diagnostic scanner adapter for the OBD connector and a smartphone/tablet or laptop with pre-installed software).

How to check engine performance using spark plugs. The main signs of engine malfunctions: the appearance of black, gray, red and white carbon deposits on the spark plugs.

Signs for determining the correct ignition timing. Consequences of an incorrectly configured OZ, methods for setting the ignition.

Purpose and design of the knock sensor. The main causes of detonation, types and operating principle of the sensor.

Why does the fuel-air mixture detonate in the combustion chamber? Reasons causing detonation. Consequences of detonation combustion of fuel in internal combustion engine cylinders.

Why does the engine overheat? What should the driver expect and what damage may occur if the engine overheats. What to do if the internal combustion engine overheats.

Common engine cooling system failures: water pump, thermostat, radiator, cooling fan and others. How to determine the reasons yourself.

Consequences. Fighting methods

Detonation of a carburetor engine is accompanied by the appearance of a metallic knock, especially under load. Many people perceive it as the “ringing of fingers” of the pistons, but the distinct sound, as if metal is hitting metal, is due to the blast wave.

The consequences of this effect, if no measures are taken, are very serious. Overheating of the component parts can lead to breakdown of the block head. The absence of an oil film, which is destroyed due to the effects of detonation, increases friction and leads to accelerated wear of the CPG elements. And finally, the mechanical impact of the shock wave together with high temperature can cause the piston to burn out, destroy the bridges between the rings, bend the connecting rod, and burn out the valve plates.

Consequences of detonation combustion of the mixture

| Piston burnout |

Valve burnout

Features of injection engines There are several ways to effectively combat this effect on carburetor engines. First of all, when detonation occurs, the fuel should be replaced, especially if the fuel was previously refueled at a station with questionable fuel quality. If the fuel does not cause suspicion, then it is worth checking the ignition and setting a later advance angle by turning the distributor.

The causes of detonation in an injection engine are identical to that of a carburetor, but in addition to metallic ringing, such engines have a number of other signs indicating the occurrence of this effect.

And all because the engine with such a power system is more advanced. Its processes of mixture formation and supply of mixture to the cylinders are controlled by an electronic control unit based on the readings of many sensors. Also, depending on the operating mode of the engine, he also independently selects and sets the advance angle. That is, the driver can no longer set the ignition on his own.

The electronic unit is able to track the occurrence of detonation. For this purpose, all injection engines are equipped with a knock sensor (DS).

Knock sensor

This sensor is capable of detecting the appearance of detonation combustion, and the ECU will take action based on its data. For example, if the cause of detonation of a VAZ-2109 engine equipped with an injection power system is low-quality fuel, and the sensor detects the effect, the ECU will simply reduce the ignition timing and the detonation will stop.

How to eliminate a knock sensor error on a Priora or features of replacing a mounting bolt

If during the check no problems were identified with the knock sensor, but errors continue to be displayed, then the sensor mount must be replaced. Why is this being done?

The DD from the factory on most Priora car models (and other VAZ models) is attached using a short bolt element, which is screwed into a hole on the engine block. The disadvantage of using a bolt is that when screwed in, its end part does not rest against the hole in the block, and thus the level of vibration transmission from the engine to the sensor is reduced. Plus, it has a smaller contact patch.

The connecting element is an important part, which not only ensures reliable pressing of the sensor, but also transmits the vibrations of the running engine. To correct the situation, it is necessary to replace the connecting bolt with an extended pin.

Why is it necessary to fix the DD on a Priora with a pin? This is a valid question, since you can use a bolt with an extended threaded part to ensure the sensor is tightened. Using a bolt will not solve the problem, because it is quite difficult to select a product that could be screwed into the block and at the same time ensure that its end part rests against the wall inside the hole. That is why you need to use a pin, which will ensure more efficient operation of the sensor.

This is interesting! In simple terms, the fastening element transmits vibration directly from the cylinder walls, where the process of self-ignition occurs.

How to replace the DD mounting bolt on a Priora with a stud? To do this you need to do the following:

- Take a hairpin of suitable length and width. In order not to look for the part and, especially, not to order its recess, we use the exhaust manifold mounting pin from the VAZ-2101 or the fuel pump (00001-0035437-218). They have the following parameters M8×45 and M8×35 (thread pitch 1.25). A 35mm long hairpin will be sufficient.

- You will also need a washer, a groover and an M8 nut of the appropriate sizes. A washer and an engraver are required. The washer ensures high-quality pressing of the DD, and the engraver will eliminate the possibility of the nut being unscrewed due to constant vibrations.

- Screw the pin (with a pin driver or using two nuts) into the sensor mounting hole until it stops.

- After this, you need to install the sensor, the washer, and then the grower, and tighten it all with a nut with a force of 20-25 Nm.

- Finally, put the chip on the sensor and reset the accumulated errors. Drive it and make sure that the engine starts working better and no errors appear on the BC.

This is the way to fix the problem with the knock sensor on the Priora. However, it is important to understand that you should first make sure that the device is working properly.