The tachometer does not work on the VAZ 2112

During the production of the VAZ-2112 passenger car (1999-2008), it was equipped with five models of electronically controlled engines, and there were only two instrument clusters.

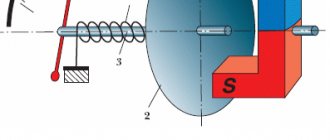

One of them was installed on the front panel, the old model, and the second, on the front panel of the new model. In appearance, they differed in the location of the instruments. On the old combination, when looking from left to right, the first instrument was the temperature indicator, and the second was the tachometer. On the new combination, the tachometer is in the extreme left position. The duties of the tachometer include providing the driver with readings of the engine crankshaft speed. The movement of the pointer along the tachometer scale is ensured by a stepper motor due to the rotation of the armature shaft on which the pointer is attached. The angle of rotation of the arrow will depend on the frequency with which the voltage pulses occur in the ignition system. Indeed, on all VAZ-2112 engines, during one revolution of the crankshaft, the spark on the spark plugs jumps twice, which corresponds to two pulses in the ignition system circuit.

But the stepper motor will not work from these pulses, so the wire from the ignition module goes to the ECM controller (electronic engine management system), where it is converted, and then through another pin the control signal is sent through the wire to the tachometer. In addition to this wire, the + from the ignition switch comes to the tachometer and one of the wires goes to ground.

If a malfunction occurs that leads to a failure of the tachometer, you will have to look for it in the three devices mentioned above: the ignition system, the ECM controller, the instrument cluster, as well as in the wires and plug connectors that form the electrical circuit for the tachometer. But, not a single device, including the tachometer, from the combination is supplied as spare parts, and in case of failure you will not be able to purchase it. This means that the entire instrument cluster will have to be changed, since it cannot be repaired.

Rarely, but there are still cases of oxidation of the contacts in the connector blocks of the instrument cluster, which is why the tachometer refuses to work. Any driver can check the condition of the plugs if desired. You just need to know in which block the required plug numbers are located. On old front panels of a VAZ-2112 car, you will have to disconnect the white block X1 of the instrument cluster and check plugs No. 1 (ground), No. 2 (low-voltage tachometer input), No. 3 (high-voltage tachometer input). And on the new front panels, disconnect block X and check plug No. 30.

Lada 2112 ᵀᴴᴱ ᴼᴿᴵᴳᴵᴺᴬᴸ › Logbook › WHY VAZ 2110-2112 DEVICES DO NOT WORK

The instrument panel of the VAZ-2110-2112 contains: speedometer, tachometer, fuel level indicator, coolant temperature indicator, 12 different indicator lamps, 6 dashboard backlight lamps, one reserve socket for the indicator lamp and two wire connection blocks.

It is very easy to distinguish the pads, the one that is white in electrical diagrams is designated as X1, and the one that is red is designated as X2. The instrument panels themselves, installed on VAZ-2110 cars, can be of two types: the old model, where the instruments are placed symmetrically, and the new model, with fuel and coolant level indicators shifted to the right side of the dashboard. The biggest malfunction of the instrument panel will be its complete failure. In this case, neither the control lamps nor the devices themselves work. The driver, first of all, needs to check the 15 amp fuse F6. It is located in the mounting block. If it burns out, it is necessary to look for the cause of this phenomenon, otherwise the new one installed will repeat the fate of the previous one, that is, it will also burn out. The cause of blown fuses is a short circuit in the electrical circuit.

There are times when instrument needles begin to jump along their scales from minimum to maximum. Most likely, the reason for such actions of devices will be poor contact with ground. The ground wire coming from the instrument panel is attached to the partition separating the engine compartment from the passenger compartment. You can find it by removing the radio from the socket. But if an alarm was installed on your car, then it is quite possible that the fastening of this massive wire, for ease of operation, was moved to another place, more accessible. Usually, alarm installers move it behind the interior trim in the area where the driver’s left foot is located. A similar picture may occur when installing a radio. When connecting its negative wire, the ground wire of the instrument panel was unscrewed, and then it was wrapped poorly, as a result of which it weakened under the influence of vibrations transmitted to the car body. They wrap it poorly because it is not very convenient to do so.

If everything is in order with the fastening of the ground wire, then you will have to check the instrument panel itself. To do this, you need to pull it out as far as possible from its mounting location without disconnecting the wires going to the pads. You will need to check on the white block X1 the ground wire going to contact 1, and at the same time check the voltage on contacts 6, 9, 10, it should be equal to 12 volts. Look, on the back side of the instrument panel, for the integrity of the paths along which electric current flows to the corresponding consumers.

Another cause of instrument panel failure may be the cigarette lighter. The fact is that through this socket, some drivers connect additional devices, such as: a cell phone battery charger, an electric tire pump, or a car interior vacuum cleaner. Considering that these consumers require high current, either the cigarette lighter itself fails or fuse F19 blows, which leads to failure of the instrument panel. By the way, you can also disable the cigarette lighter by holding it in the on position for a long time. In these cases, you can make the instrument panel work by disconnecting the cigarette lighter connector if fuse F19 is intact.

In principle, the driver himself can eliminate all malfunctions associated with a complete failure of the instrument panel. For this, he does not need any additional knowledge in electrical engineering. The only thing he needs to know is the probable causes of failure of the instrument panel.

The tachometer does not work on the VAZ 2110 injector reasons

REASONS FOR A NON-WORKING TACHOMETER

The tachometer in a car is used to indicate the number of revolutions of the engine crankshaft. Let's look at why the tachometer doesn't work and how to find and eliminate the cause of the breakdown. We will definitely dwell on the device and principle of operation, which will help to find out why the tachometer stopped working, the needle twitches or behaves inappropriately.

CLASSIFICATION BY OPERATING PRINCIPLE

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

DEVICE AND PRINCIPLE OF OPERATION

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

CONNECTION DIAGRAM

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. By its operating principle, an electric machine tachometer resembles a conventional voltmeter.

VAZ-2106 tachometer connection diagram

The “Sixes” were equipped with a tachometer model TX-193. This tachometer consists of:

- plastic cylindrical body with glass holder;

- a scale divided into zones of safe and dangerous modes;

- backlight lamps;

- a milliammeter with an arrow attached to its shaft;

- electronic printed circuit board.

The principle of its operation is based on measuring the number of electric current pulses in the primary (low-voltage) circuit of the car’s ignition system. In the VAZ 2106 engine, for one revolution of the distributor shaft, corresponding to two rotations of the crankshaft, the contacts in the breaker close and open exactly four times. These pulses are removed by the device from the final terminal of the primary winding of the ignition coil. Passing through the parts of the electronic board, their shape is converted from sinusoidal to rectangular, having a constant amplitude. From the board, the current flows to the winding of the milliammeter, where, depending on the pulse repetition rate, it increases or decreases. The arrow of the device reacts precisely to these changes. The greater the current, the more the arrow deviates to the right and vice versa.

Connecting a tachometer in carburetor VAZ 2106

Electric circuit of the speed counter of the carburetor “six”

In a contactless ignition system, the tachometer is connected not to the coil, but to the switch

Connecting a tachometer in injection VAZs

It should be taken into account that the colors of the wires and their purpose may differ depending on the manufacturer of the device, but for the standard “TX-193” device, which is usually used in “sixes”, the diagram is as follows:

- A white cable is required to connect the backlight.

- The red wire is connected to the ignition switch, a fuse is used for this, this cable supplies power when the ignition is activated.

- A white cable with a black break is required for connection to the car body.

- The brown wire connects to the K+ terminal on the coil.

- The black wire is connected to the charging current indicator relay. The latter, in turn, is installed on the right in the engine compartment.

- The gray-black cable is required to connect to the engine fluid pressure regulator installed to the left of the engine.

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Typical faults

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

- integrity of electrical wiring. In this case, it is important to check not only the signal wire, but also the ground and power supply of the instrument panel;

- quality of contacts. The presence of oxides and loose contact inside the chips may well cause the tachometer to fail;

- the integrity of the elements of the measuring unit, which are located behind the protective glass inside the dashboard. Among mechanical damage to transistors, burnout of microcircuits, tracks or swelling of resistors, the most common reason for a non-working tachometer is a violation of solder integrity. For example, on the Mitsubishi Padjero II, the appearance of microcracks in the soldering areas of the tachometer elements is a generally recognized disease.

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by the lighting of the low battery charge indicator and the sporadic lighting of a “garland” of warning lights on the dashboard.

Replacing a standard device

Before connecting the tachometer to the engine, you need to consult with specialists whether the device is suitable for your car model. Install it on or near your dashboard. The black pin (minus) must be connected to . Red (plus) should be connected to the ignition switch terminal with a voltage of 12 V. The device input wire is connected to or distributor breaker (depending on the type of ignition system). If there is a backlight, connect its wire to the headlight switch.

The video shows how to repair a tachometer with your own hands:

If in your car, the input wire should be connected to the W terminal. Some generators do not have it - then it needs to be removed with an insulated wire. To do this, the unit is removed and disassembled. You will see that there are 3 wires going from the winding to the rectifier. The insulated wire can be connected to any of them. Now all that remains is to assemble the generator.

Leave your comment on the article! We are interested in your opinion.

Each car has its own dashboard. They all differ in style and design, but what they all have in common is that they all show the same data. As a rule, this is data on the speed of the car (speedometer), as well as the number of engine revolutions per minute ( tachometer

).

Today we will talk about tachometer malfunctions. You will learn why the tachometer does not work, as well as about the main malfunctions of the VAZ tachometer

.

BEHIND THE STEEL

As practice shows, failure of the speedometer and tachometer is a fairly common occurrence.

On the one hand, such breakdowns do not affect the basic functions of the car, but on the other hand, the driver does not receive important information, which can lead to more serious malfunctions or even an accident.

Therefore, if your speedometer stops working or the tachometer needle begins to “take on a life of its own,” you need to urgently take some action.

In this article we will look at what and how to do.

Cigarette lighter failure

It is its malfunction that often causes the shield to fail. The fact is that many car owners turn on various devices through the cigarette lighter, for example, a special vacuum cleaner, chargers, pumps and other devices. Due to the fact that these gadgets require high current, either the socket itself or fuse F19 often breaks, as a result of which the instrument panel on the VAZ-2110 does not work.

In addition, the cigarette lighter may become damaged if left on for too long. In this case, you can return the instrument panel to functionality by disconnecting the socket block. But it is worth saying that such manipulation will be successful only if fuse F19 is functioning. If it does burn out, it must be replaced.

General faults

During operation, have you noticed that the needle in the car’s speedometer is inactive (at any speed)?

The first thing to do is to check the tightness of the fastening nut of the speedometer tips, as well as its drive.

If, after checking, no comments are found or the work performed does not bring the desired effect, then there is a risk of damage to the speed indicator drive or breakage of the flexible shaft.

In the latter case, the part will have to be changed. At the same time, do not forget to apply high-quality lubricant to the area near the seal (Litol-24 may be suitable for these purposes).

Once the work is done, thread the shaft through the seal - this will help distribute the lubricant over the surface of the cable.

The appearance of a knocking sound while driving may indicate a malfunction of the speedometer flexible shaft.

The reasons for this phenomenon include large bends in the cable under the instrument panel, dents, and so on. Make sure that the radii of the roundings do not exceed 10 centimeters.

Sometimes while driving you may notice a “growling” sound, approximately in the front of the car. The reason may be the speedometer cable, which often makes noise in the absence of proper lubrication.

This is one of the most important car devices. Its task is to show the number of revolutions of the engine crankshaft at a certain point in time.

A tachometer breakdown is not so critical. But in the long term, it is precisely this that can cause engine malfunction and new costs for the car owner.

So how to deal with a breakdown, and what could be the main causes of the malfunction?

In fact, there are not many of them. In the case of an electronic tachometer, the LED screen of the device most often fails. Repairs in this case are problematic - it is better to replace the display.

Nissan Qashqai tachometer contacts.

Malfunctions of the tachometer are often caused by poor contact quality or faulty wiring (in this case, impulses from the engine to the device may not arrive at all).

To eliminate such troubles, you need to carefully inspect all wires for cracks and breaks. If you find a crack, simply solder it, and if a break is detected, replace part of the wiring.

The cause of a tachometer malfunction may be a failure of the engine speed sensor.

It is not difficult to diagnose the problem - the tachometer needle begins to “jump” in different directions. There is only one way to return the tachometer to “life” - by replacing this element.

Please note that the above malfunctions and methods for eliminating them are of a general nature. Each car model may have its own nuances, and we will talk about some of them in more detail.

Malfunction of the tachometer

If signs of a malfunction appear, first you should pay attention to the general condition of the wiring. Very often, damage to the wires or lack of contact in them can cause the tachometer to break down. Various minor defects in the form of traces of corrosion, minor cracks or loose fastenings are easy to eliminate, but if the damage is serious, the wiring will need to be replaced.

An equally pressing cause of failure is the installation of silicone ignition wires instead of the standard ones. This happens because the linear resistance of silicone wiring is very different from the resistance of factory wires. As a result, the shape of the current pulse changes. If you reduce the value of the resistor on the CP board, the fault will go away on its own.

As for digital tachometers, a popular cause of device malfunction is often the breakdown of a special digital screen that shows the current parameters of the car. To resume operation of the device, you will have to change the LED display.

It is also not necessary to rule out the breakdown of other parts; it is necessary to identify which element is broken and replace it with a new one.

Malfunctions on VAZ

The speedometer on the VAZ stopped working.

Most domestic autospeedometers and odometers are mechanical. So, when a mechanical odometer fails, the main reason (almost always) is a broken cable.

This problem can be easily diagnosed by a characteristic noise in the front of the dashboard.

After breaking, the steel wires begin to touch the inside of the shell and “ring.” The main reason for the break is the large radius of curvature during cable installation.

A mechanical speedometer malfunction can manifest itself in different ways. For example, the needle on the device often lies as a “dead weight” or, conversely, shows deliberately false information.

In such a situation, you need to make sure that the speed sensor is working and that there is voltage on it. Also inspect the terminals for moisture penetration.

If there is voltage at the sensor, then the problem must be looked for in the device itself. In such a situation, it is easiest to replace it.

It happens that a sensor malfunction is associated with some kind of mechanical damage. In this case, you can try to disassemble the drive and fix the problem yourself.

If there is no voltage on the sensor, it is necessary to check all electrical connections on the way to the device - wires, blocks, terminals. It is likely that the contacts are broken or oxidized.

New cars have electronic speedometers and odometers, which receive data from the speed sensor at the gearbox.

Consequently, there can be two breakdowns - either in the odometer itself (in this case it is necessary to change the entire dashboard).

Or in the sensor (we talked about it above).

VAZ tachometer malfunctions.

In the VAZ tachometer, the causes of the malfunction may differ, depending on the type of engine.

On a carburetor car there are three wires from the tachometer.

One wire is connected to the “K” terminal of the ignition coil, and the other two supply power (respectively, “plus” and “minus”).

To find out the cause of the breakdown, you need to disconnect the terminals going to the tachometer and connect the latter directly to the battery (terminal “K” remains in place).

Now you can try to start the engine. If the tachometer does not come to life, then the problem is in the device itself or in the ignition. If the engine speed indicator works normally, then the fault must be looked for in the wiring.

VAZ-2110 tachometer connection diagram

- tachometer VAZ;

- trip computer;

- ECM;

- crankshaft position sensor;

- ignition module.

Tachometer VAZ 2110 - with four outputs: if it is on a car with injection, it is connected not to the ignition (input 2), but to the ECM controller with an additional output provided for this (input 1) - and in this case it reads the number of revolution pulses directly from the controller. It receives a signal about the position of the shaft.

Malfunctions on Priora

If the speedometer on a Priora stops working, the first thing you need to do is temporarily remove the terminals from the battery.

Did not help? – Then look for a fault in the device circuit. First, check the integrity of the instrument panel fuse.

If it burns out, replace it (but first make sure that all contact connections are intact).

If the problem persists or the fuse is normal, check all the wires on the path from the speed sensor to the instrument panel. This can be done using a multimeter.

If there are no complaints about the wiring, check the motion sensor with a special scanner. If there are malfunctions, the element must be replaced.

The serviceability of the motion sensor can be determined by the behavior of the odometer. If the speedometer does not work, but the odometer counts kilometers, then the sensor is working, and the breakdown must be looked for elsewhere.

For example, problems may be in the soldering on the dashboard circuit board or, even worse, in the gearbox. But this can only be found out at a service station with the help of a qualified technician.

As for the tachometer on the Priora, there are three causes of malfunctions:

- violation of the tachometer supply circuit. In this case, you need to carefully crimp all the tips and replace damaged wires (if any);

- violation of the functionality of the controller (the signal does not reach the tachometer). Only replacing the device will help here;

- failure of the tachometer itself. This option is the most expensive, because it is not possible to change the device separately - you need to buy a new panel.

Evidence of speedometer malfunction

Compliance with the speed limit on the road is the main thing that is required of the driver. Stopping the operation of the device responsible for this function can lead to unpleasant consequences. Therefore, timely detection of a speedometer malfunction is important.

Certain signs will help you verify that your device is faulty:

- constant position of the speedometer needle while the car is moving;

- The speedometer on the VAZ 2110 works and does not work, its needle behaves unstable: twitching, freezing in one position;

- the arrow shows the change in speed as the engine warms up to its operating temperature, then the instrument arrow stops moving, freezing at one reading;

Uncertain behavior of the speedometer needle requires checking its serviceability, finding the cause of the breakdown, and eliminating it.

Diagnosis of the causes of breakdown of the speedometer of cars with 8 valves is similar for cases where the speedometer of the VAZ 2110 injector 16 does not work.

Malfunctions on Nexia

Problems with the speedometer.

Has the speedometer stopped working on the Daewoo Nexia? The first thing you need to do is check the engine index (depending on the year of manufacture, it can be of four types).

This parameter is very important, because each of them has its own speedometer features. For example, in engines with index F16D3 and A15SMS, information to the speed indicator comes from a sensor, and with index A15MF and G15MF - through a conventional cable drive.

For cable-driven speedometers, the main problem is the breakage of the cable ends (over time, their edges simply wear off and stop working normally). To determine the problem, you need to remove the instrument panel and unscrew the nut that secures the cable.

If everything is fine with the tip, pick up the cable and try to ride a little. If there is no rotation in your hand, you need to climb under the hood and twist the nut that secures the cable to the gearbox.

Here, faults such as a poorly tightened nut, cut teeth on the gears of the gearbox, or a damaged cable tip can “pop up”.

For F16D3 and A15SMS engines, where there is an electronic speedometer, the main fault may be the speed sensor.

Popular reasons are moisture ingress or failure of the unit itself. To check the sensor, you can try to remove it and twist the shaft with a drill or screwdriver. If the speedometer works normally, then the reason is in the plastic gears of the gearbox.

The tachometer does not work.

The most common malfunction of the tachometer on Nexia is breakdown of high-voltage wires.

Often, a malfunction with a twitching arrow on the device disappears after the first pull of the wire between the distributor and the ignition coil.

Such a malfunction can be diagnosed in the dark, when sparks are clearly visible.

If everything is fine with the coil and wires, but the tachometer still refuses to work, look for a problem in the switch or the wires leading from it to the tachometer.

What is a tachometer and why is it needed?

Tachometer

- this is a device that, as I already said, shows the number of engine revolutions per minute (thousand rpm). The tachometer readings are necessary to make it easier for the driver (usually a beginner) to navigate and correctly select the desired gear (up or down). A tachometer is also necessary in order to monitor the correct operation of the engine by the number of revolutions. For example, when the speed fluctuates or is too high, a fault can be detected in time.

The first tachometers were analog (they are also called dial gauges). Analog tachometers have a dial with numbers and an arrow. One division of the analog tachometer is equal to 1 thousand revolutions. A little later, digital (electronic) tachometers began to appear on mostly Western-made cars. Data in electronic tachometers is displayed on a display (LCD or LCD display). In modern cars, digital tachometers look like analog ones because, like older tachometer models, they display information in the form of a dial and an arrow that indicates the number of revolutions.