The role of ball joints in the front chassis of most vehicles is fundamental. The ball joint provides the suspension with a stable position relative to the road and allows the steering knuckles to maneuver in terms of changing the trajectory. The part was invented about 40 years ago in Italy. Its creator is considered to be a Fiat engineer. Since then, this product has undergone almost no global design changes. These supports are also present in the design of the chassis of the practical station wagon of Russian origin Lada Largus.

Parameters of supports for Largus

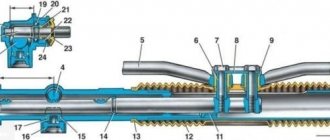

A ball joint has a basic structural unit - its load-bearing element - a special metal pin. Its lower part rotates in a hemisphere, and the upper end of this component is connected to the steering axle bracket. The hemisphere is located in the support body and rotates in a polymer shell, which is designed to dampen vibrations and prevent mutual friction of the metal surfaces of the part (hemisphere and body).

The product body itself is pressed into the suspension arm cage. To prevent dirt and other debris from getting into the working element (hemisphere), there is a rubber boot between the finger and the body.

Regarding Lada Largus. Note that on versions of the model produced before 2013, the ball joint had a pin with a groove and a diameter of 16 mm.

On modern modifications of the station wagon, the support pins have a pin increased to 18 mm in diameter, which has a side groove.

Due to their purpose, supports endure increased loads during operation, so the requirements for their reliability and quality are very high. For example, a finger must withstand the applied external force aimed at tearing it out of the body, reaching 5 tons.

To guide manufacturers in terms of quality indicators of supports, GOST 52433-2005 “Ball joints” was specially developed and implemented. Technical requirements and test methods." The provisions of this regulation must be followed not only by Russian, but also by foreign manufacturers.

Today's spare parts market will delight you with a wide range of support offers, each of which has its own catalog number, among which the following brands are the most profitable and confidence-inspiring:

- "Febi", "Ruville", "Mapco" and "Meyle" (all Germany);

- "Monroe" and "Delphi" (both USA);

- "Tork avto" (Türkiye).

The price of these products can vary by 40% or more, although the quality indicators will be approximately the same level. Here, the particular choice includes the personal preferences of the particular owner of the Lada Largus..

Diagnostics of the ball joint condition

Symptoms of the need to pay attention to the Largus ball joint are:

- there was a need to apply additional force when turning the steering wheel;

- driving over bumps, for example, a speed bump, is accompanied by a knocking sound from the front suspension;

- Uneven tire wear was detected;

- entering a turn is accompanied by extraneous sounds coming from the wheel arches;

- the steering wheel turns with a creaking or grinding sound;

- the car has become less obedient when entering a turn;

- When driving over bumps, controllability partially decreased and the car became unstable.

If you have the above symptoms, it is recommended to use the following algorithm for finding a ball fault.

- Hang it in front of Largus.

- Take the tire from above and below.

- Check that there is no play. To do this, you need to shake the wheel in a vertical plane. It should be borne in mind that the cause of movement may be not only the ball joint, but also worn steering tips or stabilizer links.

The main load-bearing element of the ball joint is the pin.

It is made of high carbon steel. On one side of the finger there is a sphere, which is located in a metal case. It is filled with polymer or grease. To prevent moisture, dirt and dust from entering, a protective cuff is placed on top. Abrasive particles and water pass through the boot freely if it is damaged. The sphere and its seat are subject to intense wear, and the lubricant dilutes and ceases to perform its functions. Therefore, when diagnosing a ball, it is important to pay attention to the condition of the boot. If cracks, punctures, holes or other holes are found, the support must be replaced.

Malfunctions, inspection and possibility of repair

Among the main reasons for premature wear of bearings is the ingress of dirt and abrasives into the hinge body. This option is possible if the protective boot breaks. The initial stage of this situation is accompanied by a suggestive creaking of the finger. There are also less difficulties when turning and unauthorized changes in the trajectory of the Lada Largus car, which runs in a straight line. This situation involves checking the condition of the supports and, if a defect is detected, urgent replacement.

It is possible to diagnose the part yourself. For this purpose, we hang out the required side of the car. We check the play of the steering knuckle by applying force to the hinge. We use a suitable mount. A worn-out product will immediately make itself known with a characteristic clicking sound inside the body of the part. If there is no play, and there are places where the shell is torn on the boot, then such a support should also be replaced, since it has very little time left to “live”.

Sometimes owners of Lada Largus. they resort not to replacing supports, but to their repair (so-called restoration). This work is very labor-intensive and requires the use of special equipment (press and other devices). You will also need to acquire polymer materials that will be integrated into the body of the product. We recommend entrusting work of this nature to professionals who have experience and equipment, although there are plenty of videos on this subject on the Internet.

DRL Largus

Lada Largus or Lada Vesta

Let us remind you that the supports are one of the parts that are responsible for safety, so the best measure would still be to replace the ball joint, preferably with the original version.

Characteristic

An integral element of the chassis of the Lada Largus car is the ball joint. This part is the connecting link between the steered wheel and the suspension wishbone. The element helps rotate the hub in different positions. The part itself has a cone-shaped shape with a ball tip (hence the specific name), which simultaneously swings and rotates. Thus, the Lada Largus ball joint ensures rotation of the hub while keeping the wheel itself in a horizontal plane. In this case, the disk can move freely in a vertical position (when the machine hits a hole or any other unevenness).

Why change and how to choose?

Significant wear of the support suggests the presence of a large gap formed by the filler of the product body and directly by the hemisphere of the pin. This condition of the part is characterized by a knocking sound that occurs when driving over uneven surfaces. If the repair is delayed, the finger may spontaneously release from the housing, which will lead to an accident.

Do not forget to regularly inspect the integrity of the support boots for damage. Over time, cracks form on the rubber surface, which develop into tears. It is also very important to check for play in the pin, because early diagnosis and replacement of the ball joint will avoid all sorts of unpleasant situations.

We recommend choosing original supports for Lada Largus. Refurbished analogues should be taken with a grain of salt. Here, the low price should not become a temptation, since the owner needs to think about the safety of both his own and those around him. When choosing, take into account the year of manufacture of your car, since the pins have differences in diameter.

How to check a ball joint without a lift

Next, we will consider in order the algorithm for searching for wear of ball joints of various types, although often the methods for checking them are largely similar, accordingly, they can be used for different types of ball joints.

How to check the upper ball joint on a car

To check the serviceability of the upper multi-link ball joint, you must follow the following algorithm (it will make it possible to check the play):

- The machine must be placed on a level surface and the hand brake applied.

- Have an assistant sit in the driver's seat and press the brake pedal. Instead of an assistant, you can fix the brake pedal using improvised means (a heavy object pressed against the pedal with a pry bar). Fixing the brake eliminates the possible occurrence of play in the wheel bearing if it is present.

- Grasp the top of the wheel with your hands and swing it in a direction perpendicular to the movement of the car, that is, away from/towards you.

Checking the upper ball

If there is play in the upper hinge on the support, then during the described check it will be clearly felt. You may also hear clicks or squeaks coming from the ball joint. However, often such a check is only suitable in case of significant wear; at the initial stage, such an algorithm may not produce results.

Therefore, it is better to use a jack to check. The algorithm will be the same, but the difference will be that you need to swing not only the upper part of the wheel, but also the lower and side ones. Specifically, you can grab the top of the wheel with one hand and the bottom with the other. Next, swing the wheel in a vertical plane . A similar check can be performed by grasping the left side of the wheel with one hand and the right side with the other. In this case, the wheel must be rocked in a horizontal plane . If there is play and “unhealthy” creaking sounds, then it is necessary to replace the support with a new one. These simple steps will help you check the ball joints without removing them and without a lift.

Replacing the ball joint

Replacing the ball joint can be done independently, but this labor-intensive operation will require high-quality tools and accessories. The instructions will also not be superfluous and will allow you to correctly carry out the entire list of manipulations.

- We hang the LADA Largus car or install it over a pit or overpass.

- We remove the wheel from the side we need (if there is a need to lift the car with a jack, then do this).

- Loosen the tightening torque of the bolt holding the transverse arm to the subframe.

- Now we disconnect the fastening of the ball pin to the steering axle.

- Next, you will need to spread the cheeks of the steering knuckle bracket to release the LADA Largus support pin. A thin chisel or a powerful screwdriver will work here.

- We lower the lever together with the support.

- We finally unscrew the fastening of the lever to the subframe and remove the product.

- We begin to press out the worn ball from the lever bracket. First you will need to remove the retaining ring. Here you will need a press. If it is missing, then you will have to do “creativity”, where a hammer and a mandrel will become your assistants.

- We act carefully.

- We prepare a new support and clean the seat from dirt. We press it into the opening of the lever until a groove appears on the reverse side for mounting the locking ring.

- After putting the stopper on, apply the lubricant included with the part into the hinge body.

- We put on the boot, which we also secure with rings.

- We install the assembled lever, but do not tighten the fasteners.

- We reinstall all dismantled components.

- We load the suspension of the LADA Largus car by placing it on the wheels. We perform the final tightening of the fastening components of the lever.

The ball joint replacement is complete. A video can also help you with this matter.

Ball joint testing methods

There are 3 main methods that allow the car owner to check the condition of the car's ball joint. The first and simplest is without removing the wheels or even jacking up the car. The second is using a jack (you need to hang the wheels one at a time). The third is using a lift. This method is only available in a service station, but this diagnostic method gives the most accurate answer to the question about the condition of the car’s ball joint. Also, testing methods differ depending on what type the ball is - single-lever or multi-lever. So let’s look in more detail at the serviceability of a ball without a lift, focusing only on the knock, play and degree of wear by the way the ball dangles in the body.

Types of ball joints

The choice of testing method depends on the type of ball joints used in the vehicle. As stated above, they are of two types, namely:

- Single lever or MacPherson type . The design is made in such a way that in the upper part the wheel and its hub are supported on a stand, and at the same time, from below, they rest on a lever with which the ball joint is in contact. This design is used in most ordinary budget cars and it is this type of device that is most often described for testing.

- Multi-link . Here the design assumes the presence of two levers - upper and lower, to which the steering knuckle is attached. In accordance with the fact that there are two levers, there are two hinges, one on each side.

Part repair or restoration?

Ball joints can only be repaired if they are slightly worn out. But doing this yourself is quite difficult. The cost of restoring ball joints at a service station is about a thousand rubles. Plus removal and installation - 1400 rubles. Based on this, a better decision would be to purchase and install a new ball joint on the Lada Largus.

The price of one element is 850 rubles (original from Renault). The cost of a part with a side groove (a kind of analogue) is 620 rubles.

Possible faults

In 90 percent of cases, the cause of ball joint failure is a leaky boot. It is a small piece of rubber that covers the joints. Over time, the anther dries out and cracks. As a result, water and dirt get inside, acting as an abrasive. Corrosion processes also form in the support, which significantly reduce its service life.

The next cause of malfunction is natural wear and tear. The service life of the Lada Largus ball joint with a side groove is from 150 thousand kilometers. This is a very reliable and durable unit. But over time it loses its strength. The part bears the load from the entire vehicle. It is at this point that the entire mass of the car (at least its front part) is concentrated. At the joint joint, the element may break (especially if the quality of the road surface leaves much to be desired). Also, at the junction of surfaces, a development is formed. This increases the gap between the part body and the pin. As a result, the Lada Largus ball joint no longer holds the wheel in a horizontal plane.

Remove the support from the lever

Now that the element has been removed from the car, we begin to disassemble it. Using a screwdriver, pry the support under the collar. We press the ball out of the lever, leaning on its edge. Next, we look at the state of the element itself. The hole in the lever should not have cracks or any breaks. If everything is in order, we clean it from dirt with a rag soaked in gasoline or white spirit, and proceed to pressing in the new support.

To do this, we need to insert the part into the hole and place a piece of pipe of a suitable diameter under the lever. Using light blows of a hammer, press the element into the grooves. Make sure there is no distortion. After this, the lever assembly with the ball can be installed in place. The assembly procedure is carried out in the same way in reverse order.