The gas tank of any car always contains vapors formed due to a decrease in atmospheric pressure or heating of the fuel. In order to prevent the leakage of fuel vapors into the vehicle, a special gasoline vapor recovery system (VPSU) is installed. Thanks to it, the vapors retained by the adsorber (essentially activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber to the manifold, a special solenoid valve is used.

Why do you need a gasoline vapor recovery system?

Injection vehicles (including Kalina), whose environmental class belongs to Euro-3, must be equipped with an EPS. This prevents fuel vapors from entering the atmosphere, polluting it. In addition, the system guarantees more stable operation of the power plant and saves gasoline. How to check the adsorber valve included in the SUBS and how it functions will be discussed further.

Replacing the adsorber on VAZ 2104, VAZ 2105, VAZ 2107

Welcome! Adsorber - someone removes it immediately after buying a car, and someone leaves it and drives until it becomes unusable, and after it arrives, they either throw it away and buy a new one, or they throw it away and continue to drive without it, turning it off in the same way at the same time, through the diagnostic connector there is an error that will then constantly light up on the dashboard (check engine) after you remove the adsorber and thereby turn off the purge valve that relates to it and do some other little things related to the hose that goes from the separator to the adsorber and with a hose that comes from the valve itself.

Note! In order to change the adsorber to a new one, you will need to take a set of tools, which will include: A screwdriver, as well as a set of wrenches, if possible (If available), also stock up on socket heads and wrenches or extensions on which you will put these heads on!

- Replacing the adsorber on a VAZ

- Checking the purge valve

- Additional video clip

Where is the adsorber located? It is located in the engine compartment of the car and if you pull the lever from the passenger compartment which opens the hood and then open the hood of the car, then after opening it will be possible to see with the naked eye where the adsorber itself is located (Indicated by a red arrow), as you see in the photo It is located inside the car engine and takes up very little space.

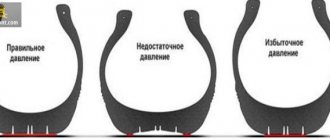

When do you need to change the adsorber? It itself fails quite rarely, usually the canister purge valve sometimes becomes unusable (we talked about how to check the valve for serviceability in the same article below), but still, when something happens to the canister itself, then after that the machine at idle, it may start to work unevenly, in addition, the pressure in the fuel tank increases because of this, when you open the tank cap, you can hear a hissing sound, like when opening any soda, there should not be such a hissing and it indicates that there is increased pressure in the fuel system may be due to the adsorber or other parts that relate to the car’s engine power supply system.

How does the adsorber work and why is it installed on all new cars? People ask us this question from time to time, as you have already noticed, this unit is installed only on those cars that are of a very recent year of manufacture, for example 2009, etc., but this unit was not installed on cars before, now we will explain why and what it is connected with.

Principle of operation

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline turns into condensate and goes back to the tank. Vapors that have not undergone treatment go through double valves of the system, one of which prevents fuel from spilling out during an emergency (for example, a coup), and the second “is engaged” in regulating the pressure in the tank. The adsorber purge valve is located under the hood, and the adsorber itself is located on the tank. The control unit ensures the normal operation of the entire system: it ventilates and removes condensation.

Good evening. How to check the adsorber valve

Not true. The line from the tank to the throttle looks like this: fuel tank-adsorber-canister valve-throttle valve (by the way, there is a vacuum there) Gasoline vapors formed in the gas tank are captured by the adsorber, which is filled with active carbon, and the adsorber valve is necessary in order to divert these vapors behind the throttle and burn in the engine. You can determine its performance simply by placing your finger on the adsorber - you should feel the operation of the valve, the vibration from closing/opening on its body. The chattering sound during operation is also audible. And in the gas tank cap there is a safety valve, which serves to protect the tank from deformation... When the engine is not running, the valve should not be purged, that is, it should be closed. If this is not the case, then either it is stuck open or something has gotten under the valve. It also happens that it jams even in the closed state... To check, you can, with the engine turned off, disconnect the wiring block from the valve, apply operating voltage to its winding (sorry, we couldn’t guess which car we’re talking about) and try to blow it through - it’s blown through, which means it’s opened , relieve the tension - it doesn’t blow through, which means it’s closed. Everything is fine. Good luck!!!

No! if the valve is faulty, then there will be a vacuum in the tank, when you open the gas tank cap, air will be sucked into the tank, it happens that the tank flattens from the vacuum in it, the top is very loud. the pump has this malfunction, but the car does not pull.

Design and operation of the adsorber purge valve

The KPA is an electromagnetic locking device that operates from the vehicle’s on-board network. The valve consists of:

- plastic case;

- valve with spring;

- windings;

- metal core;

- connector

When the vehicle's engine is turned off, no voltage is supplied to the valve and it remains in the closed position. That is, on the motor side, the system that captures vapors is blocked. At the same time, the adsorber begins to “collect” vapors. When the power unit starts, voltage is applied to the valve, causing it to open and fuel vapors to enter the intake manifold. As soon as the ignition is turned off, the control unit is de-energized and the pipeline is closed: no vapors enter the receiver.

Cars of a high price category have a more complex evaporation system. Such machines have special sensors that can “calculate” the amount of air and vapor as a percentage. This allows you to more accurately control the supply of gasoline to the injector.

How to repair the adsorber and valve

Faulty vvti valve.

Where is the VVTI valve located and how to check it It is immediately worth noting that in most cases both the adsorber and the valve cannot be repaired; accordingly, they need to be replaced with similar new units. However, as for the adsorber, in some cases, over time, the foam in its body rots, which is why the carbon contained in it clogs the pipelines and the solenoid valve of the EVAP system. Rotting of foam rubber occurs for banal reasons - from old age, constant temperature changes, exposure to moisture. You can try to replace the foam separator of the adsorber. However, this cannot be done with all units; some of them are non-separable.

If the adsorber body is rusted or rotten (usually also due to old age, temperature changes, constant exposure to moisture), then you can try to restore it, but it is better not to tempt fate and replace it with a new one.

Similar reasoning is valid for the solenoid valve of the gasoline vapor recovery system. Most of these units are non-separable. That is, the electromagnetic coil is sealed into its body, and if it fails (insulation breakdown or winding break), it will not be possible to replace it with a new one. Same with the return spring. If it has weakened over time, you can try to replace it with a new one, but this is not always possible. But despite this, it is still better to perform a detailed diagnosis of the adsorber and its valve in order to avoid expensive purchases and repairs.

Some car owners do not want to pay attention to the repair and restoration of the gasoline vapor recovery system, and simply “turn off” it. However, this approach is not rational

Firstly, this really affects the environment, and this is especially noticeable in large cities, which are not known for their clean environment anyway. Secondly, if the EVAP system does not work correctly or does not function at all, then under pressure gasoline vapors will periodically escape from under the gas tank cap. And this will happen as often as the temperature in the gas tank increases. This situation is dangerous for several reasons.

Firstly, the tightness of the tank cap is broken, the seal of which is broken over time, and the car owner will probably have to periodically buy a new cap. Secondly, gasoline vapors not only have an unpleasant odor, but are also harmful to the human body. And this is dangerous provided that the car is parked in an enclosed area with poor ventilation. And thirdly, fuel vapors are simply explosive, and if they come out of the gas tank while there is a source of open fire next to the car, a fire hazard will arise with very dire consequences. Therefore, there is no need to “turn off” the fuel vapor recovery system; instead, it is better to keep it in working order and monitor the adsorber and its valve.

Conclusion

Checking the adsorber, as well as its electromagnetic purge valve, is not very difficult even for novice car owners. The main thing is to know where these components are located in a particular car, as well as how they are connected. As practice shows, if one or the other unit fails, they cannot be repaired, so they need to be replaced with new ones. As for the opinion that the fuel vapor recovery system needs to be turned off, it can be attributed to misconceptions. The EVAP system must work normally and ensure not only environmental friendliness, but also safe operation of the vehicle in various conditions.

Signs of a malfunction of the control unit

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. It indicates that the valve is working properly. In order not to confuse this sound with the noise from a working timing belt, sharply press the gas. The character of the chatter should not change. The following signs indicate a malfunction of the control unit:

- lighting of the CHECK signal on the instrument panel;

- determination of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable idle;

- increase in CO2 content;

- a hissing sound when unscrewing the tank lid (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

How to check the adsorber, where it is located, what the adsorber is needed for

The adsorber is a specific part that appeared in the car design quite recently, with the introduction of injection engines aimed at complying with Euro-3 standards. The adsorber (absorber) is located next to the fuel tank (usually on the right), connected to it by a system of tubes and a separator, a second system of tubes connects it to the engine inlet pipe. It looks like a medium-sized, black cylindrical can, and is designed to capture gasoline vapors.

It should be noted that with a faulty adsorber, the car usually continues to operate normally, only fuel consumption increases, and the environmental friendliness of the exhaust naturally decreases. Only some fully automated car models will refuse to start if a fuel system malfunction is detected by self-diagnosis. However, an injection engine with a faulty adsorption system wears out faster.

What is an adsorber for?

Gasoline is a volatile liquid; its vapor constantly rises from the surface. If the adsorber is working properly, they enter the separator from the neck of the gas tank, condense there and return back. That part of the vapor that did not have time to condense goes directly into the adsorber.

When the engine is running, the solenoid valve periodically opens and the adsorber is purged; gasoline vapors mixed with air are blown into the combustion chamber and burned, doing part of the work. That is, these pairs are not lost. When the engine is not running, gasoline vapors are absorbed by the absorbent located in the cylinder - activated carbon, or less often - polymer absorbents. Naturally, after the absorbent capacity of the sorbent is exhausted, the adsorber must be replaced. This is a consumable item.

A faulty adsorber causes gasoline vapors to remain in the tank, as a result of which the pressure in it increases (and the gas tanks of injection cars are by no means as durable as those of older models), in addition, some of the vapors enter the atmosphere. If the machine is actively used and is practically not idle, and the adsorber has just exhausted its resource, this is not a problem: the vapors are burned out as usual. However, if the car sits for a long time, the pressure in the gas tank increases. The tank can be easily damaged, the likelihood of an explosion increases during an accident, refueling is often associated with troubles: sometimes when unscrewing the gas tank cap is literally “pulled out” by internal pressure.

If a mechanical breakdown occurs and the injection of gasoline vapor into a running engine does not work, the situation is somewhat worse: the operation of the engine is disrupted. If unabsorbed gasoline vapors are released into the atmosphere by a faulty adsorber, this reduces the environmental friendliness of the machine and can create a fire hazard in enclosed spaces (garages, etc.).

How to check the adsorber

The first sign of a malfunctioning adsorber may be a characteristic hissing sound when unscrewing the gas tank cap. If the lid begins to “knock out” from your hands, then the adsorber is already completely faulty (or has expired), and it no longer releases vapors into the air. The second characteristic sign of a malfunctioning adsorber is floating idle speed. And finally, a slightly higher fuel consumption will be noticeable with slightly worse engine performance, and the exhaust characteristics will also change (this can be determined organoleptically).

Since the adsorber is a consumable item, it is worth making it a rule to regularly replace it at the first sign of loss of functionality.

Valve check on site

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by seeing two tubes approaching it, through which the evaporation moves. Further:

- disconnect the electrical connector from the control unit by releasing the block lock;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the block connector);

- turn on the ignition: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

What does the adsorber valve do?

Many problems are related specifically to the adsorber valve. In essence, this is a very simple device that opens or closes under certain conditions (the engine is running or turned off).

If the valve works well, then there are no problems at all; you may not even know about its presence in your system.

However, when a breakdown occurs, for example, the adsorber cavity itself becomes clogged, or the valve does not work. The car may subsequently suffer serious damage. Because the cavity is not purged, and the pressure from the tank is not relieved.

How to remove the purge valve

Remove the negative terminal from the battery. If the mass air flow sensor (mass air flow sensor) interferes, remove the inlet pipe from it. Then bend the valve mount and pull it up. Now you need to disconnect a couple of fittings. The first one can be removed freely; to pull out the second one, press the latch and pry up the antennae, for example, with a thin screwdriver.

How the system works

Fuel vapor rises and concentrates at the top of the tank. When the pressure in the tank rises, vapors enter the fuel line and from there into the separator. There the process of cooling and condensation occurs. Some of the vapor settles on the walls of the separator, turns back into a liquid state and returns through the return fuel line to the tank. The other part, which did not have time to condense, enters the adsorber. The device is a regular plastic jar filled with crushed activated carbon. Vapors accumulate in the adsorber until the engine starts.

When we try to start the engine, the solenoid valve for purge the adsorber (“Kalina”) comes into operation. The signal to open it is supplied from the electronic engine control unit. At the moment of startup, the valve opens and gasoline vapors are supplied through the pipeline into the intake manifold receiver. Thus, fumes, which no one had even taken into account before, help save fuel and also do not pollute the environment.