I’ll share a little experience, in case it’s useful to someone)

I recently encountered this problem - I mean, I’m driving, I’m driving, I put it in neutral at a traffic light (or I’m squeezing the clutch), and my revs start to drop, the car practically stalls. This bullshit bothered me for quite a long time. That is, then no, then no again) In short, periodically my brain began to float. And then the singles disappeared completely. That's all! At least shit yourself. Whatever I tried, I couldn’t find the reason. Well, I think that's it, turn off the lights. We've arrived.

It's all up to chance, so to speak) I don't know why the hell I removed the terminal from the idle speed sensor, but when I put it back on, I noticed an interesting concept)) If I touch the contact on the sensor with the tip of the terminal, the idle ones appear, and if I put the terminal on, then disappear.

SHAITAN. Well, that's how it is! How the fuck?! In short, I pressed the contact, and everything worked again) Now, when some kind of crap starts with the electrics, I first move all the contacts))) What an adventure))

And also, I don’t know, whether it’s on the website or not, here’s a way to check the sensor: minus from the battery to the sensor body, plus to the sensor contact. If you hear a click, it works) If there is no click, replace it. And I think I even heard that it is better to buy a sensor with a red rubber band, and not with a black one. Better quality. But I don’t know for sure, I haven’t tried) So far the old one is shy)

The VAZ 2107 is not the best model among cars in its class when compared with foreign equivalents. However, thanks to its low price and accessible service, the car has been popular throughout the post-Soviet territory for many years. The car was produced from 1982 until 2014. That is, the oldest model is more than 30 years old. During such a period of operation, the owner will be able to encounter all types of faults and investigate most of the causes of problems.

After several years of operation, the VAZ 2107, as well as the almost identical model 2105, begins to show a new character with changes not for the better. Malfunctions associated with the power unit and its body kit are of a different nature, but are symptomatic:

- the engine stalls periodically;

- does not maintain stable speed;

- unstable operation at idle;

- hard to start;

- insufficient power;

- increased fuel consumption.

All malfunctions appear for two reasons: violation of adjustments or wear of parts.

Unstable operation of the injection engine

Usually expressed in a spontaneous change in engine speed. Observed while driving and at idle. The most common reason for low speed in VAZ2107/2105 injection units is the failure of the mass air flow sensor (mass air flow sensor).

This device controls the amount of air entering the engine. Based on this data, the ECU regulates the supply of a combustible mixture with the optimal fuel-to-air ratio under different engine operating modes. Accordingly, in the absence of this balance, engine speed begins to depend on the amount of incoming oxygen. That is, the wind blew - the speed increased, the speed died down - it decreased.

It is quite simple to make sure that it is the mass air flow sensor that is faulty. Disconnect the device connector and the ECU will switch to emergency mode. In this mode, fuel supply is controlled by the throttle position. If the car begins to behave more adequately, then the MVR is faulty. You can drive like this, but the power will drop slightly and fuel consumption will increase.

A failed mass air flow sensor cannot be repaired, except for contamination, so you can try to clean it.

Cleaning algorithm for DMVR VAZ2107/2105:

- Remove the sensor along with the protective casing.

- Unscrew the two screws and pull the sensor out of the base without touching the surfaces of the active element (straight, bent wire).

- Wash the casing with any dishwashing liquid.

- Using a bottle of cleaner for DMVR or for carburetor, based on alcohols (without acetone), carefully clean the surfaces.

- Pour generously 3-4 times, the liquid should drain.

- Dry the device.

- Reassemble the block in reverse order.

If the problem persists, you will have to buy a new device.

Methods for eliminating floating engine speeds

The diesel engine does not start or starts but is unstable. diagnostics at home

When starting to find and eliminate the reasons that cause unstable operation of the engine in idle mode, you first need to check:

- Condition of the air filter and spark plugs. If they become critically dirty, they need to be replaced.

- Integrity of insulation of high-voltage wires. If damage is found, they must be replaced.

Checking the tightness of the intake manifold (video guide)

Let's consider the remaining elements of the car, the malfunction of which can affect the smooth operation of the VAZ 2114 engine in idle mode.

Solenoid valve diagnostics

Cars with engines equipped with a carburetor are equipped with idle speed solenoid valves. Devices are checked as follows:

- Disconnect the power cord.

- Start the engine to warm up.

- Connect the wire. If a clear click is not heard, the part must be replaced.

Adjusting the idle speed on a carburetor engine (with video)

Note that the main reason for the appearance of floating idle speed in engines of this type is the incorrect operation of the carburetor. The device is adjusted by rotating the fuel quality and quantity screws.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

IAC failure is a common cause of floating engine speeds.

Serviceability of the mass air flow sensor

To diagnose the mass air flow sensor, you need to switch the tester operating mode to “voltmeter” (20 V). We check the part by following these steps:

- Let's turn off the engine and turn on the ignition.

- Let's measure the voltage at the connection connector between the contacts of the green and yellow wires. The multimeter reading should be in the range of 0.99 - 1.02 V.

The device can be cleaned by “blowing” with a carburetor cleaning aerosol

Video: Checking the mass air flow sensor

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled

Video: How to clean the throttle body

Is it possible to diagnose DPKV and DSA?

A breakdown of the DPKV and DSA (Hall sensor) is indicated by the Check Engine indicator that lights up on the car’s dashboard. Testing these devices is only possible using special instruments (oscilloscopes). You can first check the integrity of the wiring; if it is broken, the damage should be repaired.

- The DPKV sensor is installed on a bracket located in close proximity to the generator drive pulley.

- The DSA is located on the speedometer drive mechanism of the gearbox.

For a more detailed introduction to methods for detecting faults associated with engine malfunction in idle mode, it is recommended to watch the following video.

Unstable operation of the carburetor engine

The nature of the unstable speed of the VAZ2107/2105 engine with carburetors is the same as that of an injection engine, in the uncontrolled supply of air or fuel into the combustion chamber.

But in this case, the carburetor is responsible for preparing the combustible mixture. This is a completely mechanical device that is responsible for the optimal ratio of fuel to oxygen for different operating modes of the power unit.

Despite the fact that there are filters at the fuel and air inlets, they may not work efficiently, usually due to a long service life exceeding that specified in the maintenance standards. As a result, the carburetor jets become clogged with small particles.

Drivers with great experience do not stand on ceremony, they throw the VAZ2107/2105 carburetor into a bucket of gasoline for a day, then blow it out from all sides with compressed air and the carburetor seems to work normally. This is a normal solution, but flammable. Among the causes of engine malfunctions that are caused by carburetor failure are:

- displacement of the position of the adjusting screws due to shock or vibration;

- increase in the diameter of the jet holes due to wear;

- wear of the damper axis, limiting its travel;

- clogging of jets;

- failure of the float seal.

To determine the malfunction of the VAZ2107/2105 carburetor, and it will most likely be complex, start by checking the tightness of the float. To do this, remove it from the top carburetor cover (it needs to be removed). If there is gasoline in the float, throw away the float; if there is air, check in a bowl of water for bubbles. Let's say it passed the exam, then it is necessary to check the gap.

Lift the carburetor cover vertically. The gap between the float chamber and the carburetor wall should be 6.5 mm.

Install the carburetor cap and run the engine for 30 seconds. Remove the cover. The gasoline level should exactly coincide with the middle of the conical surface of the carburetor body. If this does not work, you should slightly bend the corner of the float rod.

Over time, air and fuel jets either become clogged or wear out. In the first case, they need to be cleaned and blown out. In the second case, you should check the throughput of the jets using a tank of water installed above the measured jet by 1 meter. They are connected by a tube. A volumetric flask is installed below. Measurements take place in units of cm3/min. Depending on the marking of the nozzle, the volume of liquid collected per minute in a volumetric flask should correspond.

It is much easier after 7-10 years of carburetor operation to buy a set of jets and replace them.

Those who use gas installations should know that a carburetor is not used when driving on gas. Over time, oxide forms inside dry jets, which clogs the fuel supply holes. A gasoline car may not start. It is recommended to use gasoline periodically.

Carburetor VAZ 2107 device

As you know, all domestic cars have always had and still have standard Ozone, Weber and Solex carburetors. They are still in demand today. The “seven” has a float carburetor, usually from the Ozone company. So, the diagram of the “seven” carburetor components consists of:

- Econostat.

- Dosing systems.

- Throttle valve.

- Autonomous system XX.

- Crankcase gas exhaust compartment.

- Float chamber.

- Transitional system of two chambers.

- Shut-off valve XX.

Carburetor adjustment

Adjusting the carburetor involves several steps:

- Adjust the position of the float as described above.

- Check and set the “quality” and “quantity” screws to the initial state. Screw them all the way and unscrew them 2-3 turns for the “quality” screw and 3-4 for the “quantity” screw.

- Connect a tachometer or auto tester to the “K” terminal of the ignition coil, and the second probe to the housing.

- Start and warm up the engine to a temperature of 90°C

- Use the “quality” screw to set the maximum idle speed. The gasoline supply increases when the screw is rotated counterclockwise.

- Use the “quantity” screw to set the speed higher, approximately 80-90 rpm.

- Using the quality screw, we determine whether these speeds are maximum; if not, then we repeat the procedure.

- If the position of the quantity screw does not affect engine speed, tighten the quality screw so that the speed drops by 800-900 rpm.

This carburetor adjustment may not be entirely accurate, but does not require special equipment.

Setting the float chamber level

This is the first step in adjusting any carburetor. It is on this part that the consumption and stability of the engine will depend.

The level must be at the nominal level set by the manufacturer, so it is very important to follow the technology

Setting the fuel level in the float chamber: I - carburetor cover; 2 — needle valve seat; 3 - emphasis; 4 - needle valve; 5 - locking needle ball; 6 - valve needle pull-out fork; 7 — float bracket; 8 - tongue; 9 — float; 10 - gasket.

The top cover of the carburetor is removed, but before that, you need to pump up the manual fuel pump to check the set level. The nominal level is the level of gasoline located on half of the inclined surface. If it is higher or lower, then adjust the float level by bending the adjusting antennae. The XX speed is also regulated by the float chamber.

To check, just put the cover on top, start the engine and immediately turn it off. Open the lid again and check the level. After this, you can move on to the next stage.

If the car stalls

An engine that suddenly stops not only creates an inconvenient driving experience, but also poses a safety hazard to the driver and passengers. There are several reasons.

Stalls at idle:

Stalls while driving:

- interruption of fuel or air supply due to a dirty filter;

- fuel pump malfunction;

- clogged carburetor jets;

- engine overheating.

When diagnosing a car whose engine stalls in the most unexpected places, it is better to start by checking the idle speed sensor.

It's easy to check its functionality. Dismantle the device without removing the contacts, or connect them after dismantling. Hold the device in your hands, place your finger on the cone needle and ask a friend to turn on the ignition. If you feel shocks, then install the device back. The idle speed sensor is OK.

Not enough air

Often the car starts up well and runs on choke, but as soon as the choke is turned off, the engine stalls. This indicates only one thing - lack of air. Most likely the air jets are clogged. They need to be unscrewed and cleaned. Then check that the car should not stall without suction.

There are an incredible number of reasons for poor performance of car components with similar symptoms, but only a specialist with a set of professional diagnostic tools can figure them out. But if you feel confident in yourself, go for it, VAZ service centers are already waiting for you.

What to do if the idle speed of a VAZ 2107 jumps, is there any panacea for this? The fuel system causes a lot of trouble for owners, but one thing needs to be taken into account - it is not always to blame. For example, in carburetor engines with a classic ignition system, there is a high probability of contact group failure if there is instability in the idle speed. But with injection engines everything is somewhat simpler. And now about everything in more detail.

Why is the engine speed unstable?

When it comes to the carburetor, there are several reasons:

- The carburetor is clogged, the movement of air and gasoline becomes impossible.

- The operation of the solenoid valve is disrupted - the winding is burned out or the nozzle is clogged.

- Fuel or air filters are clogged.

- Incorrect carburetor adjustments on VAZ 2107.

In most cases, the culprit is the solenoid valve. Its appearance is shown in the photo. It is necessary in the power system for the following purpose - it opens the fuel supply when the ignition is turned on and closes it when it is turned off. Consequently, the engine stops immediately after turning off the ignition.

The VAZ 2107 carburetor solenoid valve is a small device consisting of the following elements:

- Frame.

- Winding (one end connected to a metal body).

- A rod that acts as a valve that opens and closes the fuel supply at idle.

- Copper jet with holes. Please note that the jets are marked; there are several sizes.

The solenoid valve operates only when the ignition is on. If suddenly there is a break in the power circuit, you can temporarily connect the central wire of the device to the positive terminal of the battery. Just try to carry out repairs as soon as possible.

Why does the VAZ-2107 injector stall the engine at idle?

A working engine in a VAZ-2107, the injector should work if the car is started, constantly, regardless of whether the vehicle is in motion or idling. Reasons why the engine stalls at idle:

- the idle speed controller is not functioning well;

- the throttle valve, channels related to the carburetor, and injector are heavily contaminated;

- the idle jet is dirty;

- it's time to clean the fuel pump and air filter;

- The mass air flow sensor and the sensor that reads the throttle position have refused to function;

- The crankcase ventilation mechanism of the VAZ-2107 engine is clogged.

To fix these problems, you need to remove each part and thoroughly clean it from dust and dirt.

Assess the condition of the components; if it is far from ideal, there are chips and deep dents, it may be better to completely replace the old part with a new one.

Preparing to adjust the idle speed

If you do not plan to clean and disassemble the VAZ 2107 carburetor, then one of the tools you will need is a screwdriver. A device for measuring the speed (tachometer) is installed in the dashboard. But it’s worth getting a mixture quality indicator. With its help you can create an air-fuel mixture in ideal proportions. This article will talk about adjustment using this device.

Before starting work, you need to warm up the engine to operating temperature. Let us remember that this is a temperature of about 90 degrees. You also need to put the air purification filter in place to simulate normal engine operation. Make sure the float is adjusted correctly. The fuel level in the chamber must always be stable.

There are also many requirements for ignition and gas distribution. Be sure that all clearances must be correct, and the ignition timing must be adjusted for the gasoline used. And most importantly, open the air damper completely while making the adjustment. That's all, the preparation work is briefly summarized, now you can begin the idle adjustment procedure.

Setting the idle speed of the VAZ 2107

Carefully inspect the carburetor, there are several screws on it - the quality of the air-fuel mixture and quantity. It is with their help that we will now try to adjust the carburetor. Of course, not every driver has such a device as a gas analyzer. However, not everyone cares about the level of CO in the exhaust. For convenience, it is advisable to have a digital or dial tachometer. You can find how to connect it correctly in the corresponding article on our website.

So, start the engine and turn the quality screw. Listen to the engine, you need to stop at the moment when the crankshaft speed is at its maximum. After this, you begin to rotate the quantity screw and achieve a frequency of 1100. And the last step is to set the frequency to 800-900 using the quality screw. Please note that if necessary, the idle speed adjustment must be repeated.

Replacing the idle speed sensor

The idle speed sensor of the VAZ 2107 can only be removed together with the throttle body. To avoid burns when performing work, you must ensure that the engine is cool. To dismantle the sensor, perform the following operations:

After removing the sensor, you need to check the O-ring located at the mounting location of the idle speed sensor. If it is cracked or inelastic, it must be replaced.

Checking the idle speed sensor consists of monitoring the resistance between the terminals of its windings. Between AB and CD it should be approximately 53 Ohms, between AC and BD it tends to infinity. If the resistance is different, the idle speed sensor must be replaced with a new one.

Before installing a new sensor, you need to check the amount of protrusion of its needle. It should protrude no more than 23 mm. You can check this like this:

Apply plus to terminal D of the VAZ 2107 idle speed sensor.

Touch the ground wire to terminal C of the idle speed sensor. The needle will move out a little. Using repeated touches, simulating impulses from the power source, push the needle so that it takes the extreme position.

Use a caliper to check the size of the protrusion. If the needle protrusion is more than 23 mm, the sensor must be replaced with a new one.

Before installing the idle speed control, it is necessary to lubricate the rubber O-ring with machine oil.

Installation of the idle speed sensor occurs in the reverse order of removal. During installation, it is necessary to check the serviceability of the band clamps and, if necessary, replace them. It is also necessary to take into account that it is necessary to install the throttle body only on a new gasket.

As part of eliminating illiteracy on the basics of adjusting, tuning and repairing carburetors on the VAZ-2107, we are conducting a series of publications focusing on the main nuances and “secrets”, based on the experience of our colleagues from the forum. So, today we will tell you how to correctly adjust the idle speed on a VAZ-2107 carburetor without having a gas analyzer at hand, but guided only by the tachometer readings. The need for adjustment arises among owners of VAZ classics quite often. Signs - the engine idles unstably, stalls, troits, etc. So, let's go, this procedure is described in simple 6 steps for adjustment.

We draw your attention to the location of the quality and quantity screws on the OZONE carburetor for the VAZ-2107

1.

We set the nominal crankshaft speed using the mixture quantity screw on the carburetor (for “classics” it is 820-900 rpm).

2.

quality

screw , we find its position at which the speed will be

maximum

.

3.

the quantity

screw , set the speed 15% higher than nominal (for “classics” this will be 950-1035 revolutions/min).

4.

We check that the position of the quality screw provides the maximum possible speed for a given position of the quantity screw.

If this is not the case, then use the quality screw to achieve the maximum possible speed and use the quantity screw to restore the speed above the nominal speed by 15%. We again check that the position of the quality screw provides the maximum possible speed, and return the speed with the quantity screw to +15% of the nominal value. Etc. until the moment when, at a rotation speed 15% higher than the nominal one, any rotation of the quality screw will only lead to a decrease in speed.

5.

By tightening the quality screw, we reduce the speed to nominal.

6.

We check and make sure that the car’s engine runs smoothly, without “tripping” at idle and does not stall when the throttle is closed abruptly

Briefly, all this can be stated as follows:

1. Find the position of the quality screw at which the speed will be maximum. 2. If necessary, use the quantity screw to set the speed 15% (130...150 rpm) higher than the required XX speed. 3. see point 1 4. see point 2 5. When it is no longer necessary to adjust the speed with the quantity screw, by turning the quality screw we reduce the speed by 15%, i.e. to the required idle speed.

What to pay attention to:

If the adjustment is made correctly, then when you remove the terminal from the solenoid valve or the vacuum hose from the fitting of the “quantity” adjusting screw housing, the engine should immediately stall.

If, when you tighten the “quality” screw all the way, the engine does not stall, then most likely one of the throttle valves is too open - adjust the locking screws.

Pay attention to the return spring and the “gas” drive. The throttle valve should clearly return to its original position when the gas pedal is released.

For the summer season, the idle speed can be set to 800 - 900 rpm, for the winter it is better to 900 - 1000 rpm. This is due to the fact that in winter the load on the vehicle’s on-board network is usually higher.

VAZ 2107 carburetor. RPM drops at idle

- the settings are usually not lost. It’s either bad gasoline or some kind of speck got in somewhere, which could be more likely. you need to remove the top part of the carb and blow out all the channels and jets, most likely the idle speed will fall into place.

- Try it.

- If the fan turns on. cool, then the speed will naturally drop!

- It’s not just the carburetor, but the ignition is also important...

Wash the carburetor, adjust it with the IKS-1 device, check the distributor for bearing wear (should not be loose)..., contacts (if any..) for cleanliness and set the gap. Use a stroboscope to check the angle and operation of the vacuum and centrifugal regulators. At the same time - all the hoses where there may be an air leak. . The mark should run along the pulley - where it should be (if you understand - easily..). I always did this myself on the classics - it worked like a clock.IKS-1 is a cool device for tuning carburetors..))

- The idle speed screw is responsible for idling; it is located on the carburetor, just do not confuse it with the enrichment adjustment. Rather, it is acting up, its design is a bit of a mess. It costs a penny to assemble and changes quickly. Perhaps you need to disassemble the carbure, there is a gasket that swells over time and blocks the idle channel, as an option, trim it, or buy a repair kit for the carbure, just look at which carbure. It’s more complicated, but replacing the gaskets sometimes helps. It’s possible to do everything yourself, and the service costs about 500-800 rubles. 800 rpm is normal, but the fact that they jump is not good, maybe the quality of our gasoline.

- They beat the guy's head, and the car can be sold for 5 rubles / joke / and now seriously, there is a shut-off valve on the side under the filter housing / the wire fits like a little bottle / father / mother / I think the key is 13, turn it out and do the following: clean the jet /v the bronze core, it is pulled out with pliers using a cloth + when you put the wire in place, lean the shut-off valve body against ground and turn on the ignition, you should hear a clear click, i.e., pulling the shut-off valve, i.e., opening the valve. Then you select the idle speed screw / it is screwed horizontally into the carburetor body / stable idle speed. stroke / ON A WARM ENGINE / based on the tachometer 700 - 750 rev. Then, using the quality screw / it stands at an angle in the body /, you select the maximum speed at the peak and the quantity screw, i.e., idle speed rev. extinguish them until cold. progress and again trying to increase the speed at the expense of quality

- -In your case, there are a lot of options - the simplest is a speck in the carburetor, - the saddest is piston burnout... I personally encountered

- The 7-carb engine should operate stably at 850 rpm without tripping or fluctuations. If there are vibrations at such speeds, then either the engine mounts are worn out, or there are problems with the injection or ignition system. Try adjusting the quantity and quality settings on the carburetor. Place a friend near the tachometer and by ear adjust the speed and uniformity of engine operation. As soon as you think you have found a good mixture, take it off the gas. When you have everything set up, turn it off and start it again and see how the car behaves. If it still doesn’t work well, then go deal with the hardware. first of all, unscrew all the spark plugs and look at the condition - if there is oil, get ready for repairs

- the epkh system needs to be looked at

- Clean the idle air valve

- 1. Check the EPS system (if any).

2. Check the carb (fuel level in the float chamber, XX, blow out, clean the carb, replace the air filter, or rather the filter element, adjust XX, adjust the microswitch). 3. Replace gaskets on the intake/exhaust manifolds. 4. Replace the fuel pump diaphragms. 5. Tighten the bolts on the carb, on the filter (pan). It helped me, I hope some of the points will help you too.

Carburetor VAZ 2107 idle

is ensured using a forced idle economizer system (EFI).

In order to detect a system malfunction, this article describes methods for checking and replacing all components of the forced idle system of a VAZ 2107 carburetor.

What about the injector?

Everything is a little simpler here, since no adjustments are needed. The reason is that a smart on-board control system is responsible for everything. And specifically for idling - the regulator (IAC). Some may call it an idle speed sensor, but this concept is completely wrong. The fact is that there are two types of devices on injection cars - sensors (reading) and actuators. The idle air control is a stepper motor; it does not measure anything, but on the contrary, it opens and closes the air supply through a special channel.

A breakdown of the IAC can only be determined by external signs, and then only relatively. The fact is that the control lamp on the dashboard will not light up if the regulator suddenly fails. But if you feel unstable revolutions, or they have disappeared completely, and the engine jerks and stalls, then first of all, of course, it is worth checking the performance of the IAC. It is worth noting that sometimes the “Check” can light up when the IAC is faulty. This happens if the engine detonates. The knock sensor signals a malfunction to the electronic control unit.

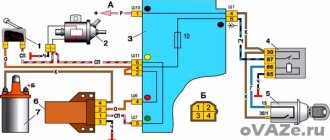

Checking the electro-pneumatic valve control unit.

You will find the control unit for the EPHH electro-pneumatic valve on the left mudguard in the engine compartment.

Gradually increase engine speed. At engine speeds of 1500–2000 rpm, the voltmeter readings will drop abruptly to 0.5–1.5 V or the warning light will go out.

We replace the faulty unit with a new one, for this...

4. ...disconnect the connector...

5. ...and use a screwdriver to unscrew the two screws securing the block to the mudguard. Next, we install the new EPHH block in reverse order.

IAC breakdowns

If you have a VAZ 2107 with an injection engine, then pay due attention to the condition of the vehicle systems. If the speed on an injection engine fluctuates, then you need to look first at the idle speed control. The fact is that the breakdown of such a mechanism as the IAC can lead to very sad consequences, including a traffic accident. Here are the main signs by which you can independently determine whether the regulator is broken:

- The engine begins to “live its own life” - the crankshaft rotation speed is constantly changing, sometimes decreasing, sometimes increasing. Consequently, the tachometer needle constantly floats.

- When you start a cold engine, the crankshaft speed does not increase, it fluctuates within a certain range.

- If you turn on powerful electrical appliances (for example, a car radio, low or high beam), the speed decreases and does not return to the set level.

- When you engage the neutral gear, the engine begins to stall if you do not apply the gas pedal from time to time.

These are the main signs that the regulator is faulty. In fact, any interruptions in the idle level are the first sign of a breakdown or minor defect in the IAC. But the time has come to diagnose it. It won't be difficult to do this.

Carrying out diagnostics

The simplest method is to measure the voltage at the block to which the regulator is connected. These are terminals D and A. When the ignition is turned on, a voltage of 12 V should be present on them. If the voltage is less than this value, it is worth looking at the battery and generator. It is quite possible that the battery is undercharged. In the same case, if there is no voltage at all, it is necessary to check the entire power circuit of the device and diagnose the ECU.

Set the multimeter to resistance measurement mode. Between pairs of terminals A and B, C and D, there should be a resistance of approximately 53 ohms. Remove the IAC and connect (with the ignition off) to the block. Then turn on the ignition and look at the behavior of the needle - it should extend completely when voltage is applied. If this does not happen, we can judge that the IAC is broken.

Sometimes simply cleaning the regulator helps. To do this, you can use sprays, of which there are sufficient quantities in stores. But in some cases, only replacing the device will help. Of course, this is not a DAAZ carburetor, the cost of the IAC will be many times lower, and there will be no problems with replacement. If, even after the replacement, the engine does not idle, it is necessary to fully diagnose the injector.