Signs of a Solex carburetor malfunction

Before adjusting the carburetor on a VAZ 2109, you need to familiarize yourself with the associated faults so as not to repair the unit just like that.

So, the reason after which the VAZ 2109 carburetor is adjusted is considered:

- Fuel mixture too rich. Experienced auto mechanics know that for an ideal ratio of fuel and air, a value of 1 to 15 is required. This means that for the combustion of 1 kg of fuel, 15 kg of air are needed. If the mixture is called rich, it means that the fuel level is higher than the nominal level.

Symptoms: the engine is difficult to start, black smoke from the exhaust pipe, spark plugs with black soot and lumbago in the exhaust system. The fuel supply system quickly becomes clogged.

- The air/fuel mixture is too lean. A lean mixture means that too little fuel is supplied. Because of this, the car loses dynamics and increases the amount of fuel supplied. In some cases, gasoline savings are observed, but spark plugs fail faster. A lean mixture is accompanied by an increase in engine idle speed.

The following signs can be called a consequence of the previous ones and this is:

- Unstable idle speed;

- Increased fuel consumption;

- Deterioration of starting properties;

- Reduced engine response.

The operating principle of the carburetor and fuel supply system forces car owners to perform such a procedure as adjusting the VAZ 2109 carburetor at least once every six months. The mechanism on a car with a carb needs to be lubricated once a month, unlike a car with injection, which has injectors. Everything is extremely easy to adjust.

Reasons for failure of the VAZ 2109 carburetor

The Solex carburetor is a very sensitive device, which contains a large number of small channels. When a huge amount of low-quality fuel passes through them, you may encounter the fact that they become clogged with impurities and stop functioning.

The first thing that may immediately become noticeable is a decrease in idle speed. In the future, the car does not start well and needs carburetor adjustment.

This procedure is divided into several stages:

- Removing the unit

- Disassembly and cleaning

- Assembly and installation

- Carb idle adjustment

Quality screw removal method

With Solex carburetors, the XX channel in the body itself often becomes clogged, and in order to clear it thoroughly, it is necessary to remove the quality screw. But this screw, as mentioned above, has a very tight fit and is not easy to get out. There are several methods for dismantling a part; we will consider only one option.

We take a piece of an old antenna from any radio receiver, select the outer diameter so that the tube fits into the channel of the carburetor body, usually the outer thickness of the “puller” is about 4 mm. We cut off a small piece, make a cut at one end (about 1 cm deep), use another quality screw (a spare one, or you can buy it specially in a store), and check how tightly the tube fits onto the head of the screw.

Now you can unscrew the screw and use a homemade puller to remove it from the KU body.

Related articles:

- Features of working with Movil, user reviews The bodies of modern cars are able to resist through corrosion for an average of 5 to 10 years, then gradually rust begins to “eat up” the body parts, over time on the bottom, […]

- Solex carburetor 21083: design, adjustment, tuning Front-wheel drive VAZ 2108-09-099 cars were equipped with carburetor engines for a long time, and only closer to the beginning of the 2000s did […]

- Advantages of the Volvo V40 Cross Country hatchback Volvo cars have always been famous for their high reliability and excellent technical characteristics; quality is the main trump card of the Swedish automobile industry. The Volvo V40 Cross Country also does not […]

Removing, disassembling and cleaning the carburetor VAZ 2109

If all of the above symptoms are detected, you can begin to remove and disassemble the carburetor. On a VAZ 2109, repairing a Solex carburetor is possible using a repair kit. It is recommended to purchase a repair kit in advance to immediately replace all gaskets, jets and valves. The table contains data on jets and all necessary valves. The machine must be stationary. When sorting out the parts, the most important thing is not to lose anything.

To remove and configure the device, you need to open the hood and disconnect all the hoses from it. They are mounted on clamps, so it is recommended to stock up on a screwdriver in advance. The next stage is the cable for driving the gas pedal and air damper. Both elements can be removed quite easily. After this, remove the chip from the idle speed economizer. Dismantling is carried out extremely carefully so as not to damage the contacts. Taking everything apart is even easier.

Recommended flow rates of pneumatic economizer jets for various operating conditions

| Operating conditions | Flow capacity cm³/min | Operating conditions | Flow capacity cm³/min |

| Light road conditions with heavy loads (economical adjustment) | 60 | Average road conditions | 110 |

| Working with a trailer (economical adjustment) | 160 | ||

| Working with a trailer (power adjustment) | 200 | ||

| Light road conditions | 80 |

You can now remove the four housing nuts that hold the carburetor to the intake manifold. If it is difficult to remove, you can pry it out with a thick screwdriver. Clog the manifold with a rag to prevent foreign particles from getting inside and clean the seating area of any remnants of the old carburetor gasket.

The carburetor itself consists of several elements:

- Top cover

- Bottom cover and float chamber

- Throttle valve block

First of all, the top cover is removed. At the same time, the condition of the needle valve and the condition of the float are checked. The valve should move without jamming and also easily return to its original position. You can immediately check the operation of the accelerator pump drive. All connections should turn easily. The operating principle of many mechanisms is very simple, and they must stand level. It is configured after assembly.

Now you need to separate the throttle body from the bottom cover. Everything is held in place with bolts, so a screwdriver will suffice. Once all components are completely disassembled, they need to be treated with throttle body cleaner or regular gasoline. Parts should be wiped with dry rags.

The jets deserve special attention. They need to not only be cleaned, but also blown out. The thing is that the jets have very thin channels that are easily clogged with foreign particles. Even one speck is enough to disable the entire unit. Disassembling and reassembling the carburetor is half the battle. Now you need to carefully install and configure everything. The hoses are connected without sealant.

If you have any questions, watch the video:

What to do if the carburetor of a VAZ 2109 is clogged

Increased fuel consumption - eliminating this problem on the VAZ 2109

How to set the ignition angle?

Many people recommend using a strobe light for these purposes. But this is true for new cars. If the motor is already worn out, this angle set by the strobe will be incorrect. It is best to rely on the hearing and behavior of the car.

So, how do you set up the ignition yourself on a VAZ-2109? By the way, we have already examined the carburetor in full. The first step is to start and warm up the engine. Then you need to loosen the nuts holding the distributor and turn it in one direction or the other until the speed begins to increase and the engine starts running stably. Next, the nuts are tightened.

After this, you need to drive the car and look at its reaction. If the car “does not drive,” then the ignition is too early. Next, you need to accelerate to 50 kilometers per hour, engage fourth gear and press the accelerator pedal. If detonation sounds occur, then the ignition is set even later. If the detonation lasted a few seconds, then everything is in order. And if it is not there at all, then the ignition is too late.

It is recommended to set it again. But in this case, the ignition distributor should be rotated in the opposite direction. Please note: the slightest inaccuracy and an error of 1 degree are fraught with detonation. After successful setup, the car will begin to pick up speed normally and consume less fuel (but not below factory settings).

Installation and assembly of the VAZ 2109 carburetor

After cleaning all the elements, you can assemble it. Check the clearances in the throttle valve block in advance and set them to the nominal values. For each type of unit, you can find all calibration data in reference books. Instead of old gaskets, it is recommended to immediately install new ones to avoid repeated disassembly after two weeks of operation. Installation of parts is done carefully.

Replace the needle valve if necessary. A faulty valve can negatively affect fuel consumption, as it backs up and allows a huge amount of gasoline to pass through the channel cross-section.

It is recommended to lubricate the damper drives, levers and rods with Seledol or Litol 24. It is not recommended to use this lubricant in an environment that comes into contact with gasoline. The grease is suitable only for external parts, such as the plastic joints for the carburetor rods. They may not stand.

The top cover is installed last and only after adjusting the level in the float chamber.

Do-it-yourself carburetor float chamber level adjustment

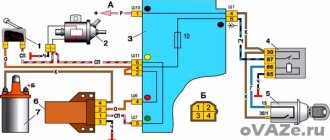

Diagram of the float chamber with installation parameters: 1 - float; 2 - tongue; 3 - gasket; 4 - cover.

The level in the float chamber is necessary for smooth operation of the carburetor. A level that is too high will increase the fuel supply, while an insufficient level will reduce the throttle response of a carburetor engine, since the level will not be able to rise in time.

To adjust the level in the chamber, you need to turn the top cover over and bend the float as far as the antennae allow. The distance between the bottom corner and the cover should be 20 mm. If not, bend the tabs and install the top cover. This do-it-yourself adjustment of the VAZ 2109 carburetor is considered nominal. The principle of action here is simple.

Ignition settings

In order for the car to drive as efficiently as possible, adjustments to one carburetor are not enough. You also need to adjust the ignition. The VAZ-2109 carburetor should work well. Do you know that an incorrectly set ignition angle affects engine performance for the worse?

On front-wheel drive VAZ models, this should be taken very carefully. The ignition angle allows you to obtain normal characteristics such as power, idle speed, fuel consumption, and engine response.

Adjusting the choke or trigger

Install the carb, but do not install the air filter. Pull the choke out completely and close the valve. In this position, you need to adjust the air damper cable.

Try pulling out and removing the choke several times. The damper should open and close completely without jamming. If everything is done correctly, you can install the air filter in place, connect all the hoses and carburetor drives. It's time to start adjusting the idle speed of the VAZ 2109. Don't forget about connecting the EPHH.

How to set up the carburetor correctly on a VAZ 2109?

The nominal speed of the VAZ 2109 engine should correspond to 750-800 rpm. Adjusting the XX carburetor is necessary to economically maintain engine operation while parked and to warm up as quickly as possible before driving. Without this, the device will not work. Table from those. carburetor characteristics does not have such data. This must be done according to the following instructions, which contain the XX norm. The results and adjustment scheme are stable speeds.

This procedure is carried out if there are problems with the engine or once every six months in accordance with the regulations on technical maintenance of the VAZ 2109. You only need to spend 3-4 minutes on it. The engine warms up to operating temperature using choke or using the accelerator pedal. Next, remove the choke and fully tighten the quality screw. Most likely, the engine will stall. Now the screw is unscrewed exactly three turns and the engine starts again.

Using the quantity adjusting screw, the speed is set to 650-700 rpm. Now turn the quality screw until you get the highest possible idle speed. Again we set the number of revolutions equal to the nominal one. Now we need to rotate the quality again until we get maximum speed. You can regulate this way for a long time.

Now turn the quantity up to 800 rpm. This adjustment is considered correct. If this was not achieved the first time, you need to repeat the procedure again. It is worth recalling that the entire procedure is performed with the headlights on low beam and the stove operating at maximum mode. This is due to the fact that when the voltage drops, the speed drops, so when using these consumers, the speed should be nominal, and when turned off it should increase slightly.

The quality and quantity screw on the carburetor of the Lada 2109 car is located at the rear of the unit. In this regard, adjustment becomes more complicated. Although, it becomes more difficult to regulate, but not as often as on a Zhiguli.

Excellent video on fine-tuning the Solex carburetor on a VAZ 2109

What to do if there is no idle speed on the carburetor nine

Adjusting the float of the "nine" carburetor

Setting up floats in Solex chambers is a simple procedure that does not require the use of specialized tools or special skills.

However, in the factory, this procedure is partially automated and is performed using a special template, which significantly simplifies the adjustment. But if you do the work yourself, you don’t need a template, but we will need the following tools and equipment:

- two screwdrivers, with a flat head and a Phillips head;

- a caliper or ruler (it is better not to use metal, wood or plastic);

- a piece of wire with a diameter of no more than 2 mm (you can use a thin drill or a similar round rod).

This set is sufficient to perform the entire range of adjustment procedures.

Classic method

In accordance with the recommended method, adjusting the fuel level of a Solex carburetor is carried out in stages in the following sequence:

- start the engine and let it run for a couple of minutes to fill the carburetor chambers with gasoline;

- Structurally, access to the carburetor is blocked by the air filter, so it must be removed along with the housing. This is done simply: unscrew the top nut, unfasten the side fasteners to remove the cover, remove the filter itself, and then dismantle the air filter housing by unscrewing the 4 fastening nuts;

- after lifting the case, it is necessary to disconnect the rubber pipes from it;

- now we perform the same operation with the fuel pipes connected to the carburetor; when removing them, there is a risk of spilling gasoline remaining in the system, this circumstance must be taken into account;

- now you need to disconnect the wire going to the solenoid valve of the XX system;

- the turn has come to disconnect the air damper drive (the cable coming from the choke handle);

- you can begin to remove the Solex cover, which is secured with five screws;

- After the carburetor cover is put aside, you can immediately measure the current fuel level in the PC using a caliper depth gauge or simply lowering the ruler down all the way. Normally, this distance should be within 2.5-2.6 cm; if this is the case, subsequent adjustment of the fuel level of the Solex carburetor is not required;

- if the gasoline level is less or more, you need to inspect the mechanism for attaching the floats, and if everything is normal, adjust them;

- to do this, place the previously removed cover on a horizontal surface, the floats will be at the top;

- We carefully examine the relative position of the elements. The outer sides of the floats must be strictly parallel to the imprints made on the gasket. If there are distortions, this may cause the floats to come into contact with adjacent surfaces and parts, which leads to a change in the fuel level. The problem is solved by bending the fastening levers so that after this the floats move freely and do not touch anything;

- if this is not the case, measure the distance between the gasket and the floats. This gap should be equal to two millimeters, for which we needed a wire of the appropriate diameter. If the distance does not correspond to the standard, bend the tongue through which the float pushes the valve (needle). After this, we measure the height of the floats (guideline - 3.4 cm). If it was not possible to achieve the specified distance, we repeat the procedure with bending the tongue until we achieve the goal;

- The final stage of the procedure is measuring the working chord of the floats. The principle is simple: we install a caliper near the float, measure the distance from the surface of the Solex cap to the lower edge of the float, and then lift the float with our hands until it stops. We fix where its lower corner is now located. Normally, the working stroke should be 1.5 cm, if it is more/less, we again turn to the procedure of bending the float tongue.