Why do you need oil?

Is oil the lifeblood of the engine? This is not entirely true, of course, the comparison is very rough, but still, the engine will not function without oil (or it will, but not for a very long time). Modern motor oils lubricate and protect all rubbing parts, and these are pistons (with their rings), shafts, bearings, etc. Let's just say that good oil extends the life of the engine by many thousands of kilometers.

BUT oil must flow through the system, just like blood itself through human vessels, if the oil is simply poured in a pan and does not go to the rubbing parts - IT IS USELESS!

Functions, structure and location of the VAZ 2110–12 oil pump

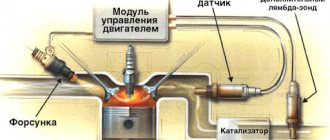

The engine lubrication system is designed to timely supply engine oil to the moving and hottest elements of the power unit. Oil is supplied from the sump and circulates through special channels inside the block and cylinder head. The oil pump ensures forced circulation of the lubricant.

Location of the oil pump on the VAZ 2110–12

On the VAZ 2110–12, the oil pump is located in the lower right corner of the cylinder block under the crankshaft gear, which drives the gas distribution mechanism.

The oil pump is located in the lower right corner of the engine under the crankshaft gear

This applies to both eight and sixteen valve engines. The pump housing is also the side cover of the power unit.

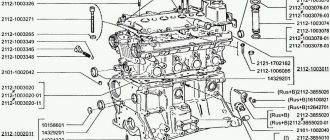

Oil pump device

The design of the oil pump is very simple and includes the following elements:

- housing with lid;

- driving and driven gears;

- pressure reducing valve with spring;

- oil receiver

The oil pump has a simple design based on two gears

Operating principle of the oil pump

The pump is driven by the crankshaft through the drive gear. The latter rotates the driven gear, creating a reduced pressure at the input of the device and increased pressure at the output. Thus, oil from the crankcase flows through the oil receiver tube into the pump, and from it into the engine oil line. When the pressure inside the pump begins to exceed the permissible value, a spring-loaded pressure relief valve drains excess oil back into the sump.

What builds up oil pressure in the system?

Everything is simple here - there is a special oil pump that takes oil from the engine sump and pumps it through the system.

It is usually installed in the engine sump and driven by special gears that the engine turns during operation. Oil begins to flow through many channels to the right places under pressure - this is the crankshaft and its bearings, the camshaft and its “bed”, pistons, and much more. It is the pump that is responsible for the pressure; if the pump stops, the pressure indicator will drop to zero. THIS CANNOT BE ALLOWED! Because the engine will not be lubricated at all, which will lead to instant breakdown, especially at high speeds.

BUT often the oil pump does not stop, but simply begins to pump worse, this indicates its wear, which is why you need to know the oil pressure in the engine! To respond in time to the nearest oil pump failure.

Purpose

The purpose of the oil pump is to circulate oil through all engine components to lubricate them evenly and increase their service life. It is driven by an internal combustion engine (internal combustion engine) and is structurally divided into two different types, based on the principle of coupling with the crankshaft. In our case, it connects directly to the crankshaft, that is, it rotates with it. This is the operating scheme of the unit for front-wheel drive VAZ cars. Cars with all-wheel drive, as well as classics, have a more complex system installed. There, the drive contains additional links: an intermediate shaft, a timing chain (gas distribution mechanism), and toothed gears, through which torque is transmitted from the crankshaft to this device.

Common faults

- Most often, the pump of the VAZ 2112 and other VAZ models with front-wheel drive leaks through the seal, which has to be changed.

- The oil receiver also often fails, especially if you use low-quality oil, or missed replacing it in a timely manner, or the oil does not meet specifications (too thick).

- Too liquid simply will not be pumped and the pressure sensor will immediately light up.

- In this case, the oil receiver mesh becomes clogged, the circulation of oil through the engine becomes difficult, causes oil starvation, and as a result, the service life of the engine is significantly reduced.

- This includes a malfunction of the pressure reducing (bypass) valve: either it is stuck in the open position, and then the oil pressure drops. Either it does not bypass, and then the oil will squeeze out through the oil seal

What oil to fill and at what frequency?

The manufacturer recommends changing the engine oil after 10 thousand kilometers, however, it is recommended to shorten this period if possible, and at the same time change the oil filter. You should only buy oil from well-known companies and, when choosing it, beware of counterfeits . The ideal option is to pour oil recommended by the manufacturer and not be fooled by cheapness or high cost (expensive does not mean high quality).

Recommendations for choosing spare parts

- The oil pump usually does not cause car owners much trouble, since it has a service life of at least 120 thousand kilometers. However, no one is immune from breakdowns

- If suddenly you still need to replace the oil pump on a VAZ 2112, it is better to take original spare parts and not save

- Among the well-known suppliers of parts for VAZ cars, the official one is the Tolyatti Automobile Assemblies Plant (TZA for short).

- It also produces oil pumps for the VAZ 2112

- This is one of four varieties of such units in the VAZ line, which fits all front-wheel drive fuel-injected cars

Helpful advice: To avoid serious consequences for the car and major engine repairs, it is important to monitor the indicators on the dashboard. If the oil pressure lamp flashes at idle speed, and replacing it does not solve the problem, the lamp lights up again - this means there is a breakdown. When the warning light suddenly comes on and the performance of your car’s engine is alarming, it is recommended to turn off the ignition and call a tow truck to a repair station. This will save money on subsequent engine repairs (continuing to drive the car under its own power in such a situation, you risk serious damage to the engine).

- Typically, removing the oil pump on any car occurs when disassembling the engine.

- Only if necessary, this work is carried out on the car without removing the engine from it.

- Before starting this procedure, first drive the car into the inspection hole.

- And immediately purchase everything you need to carry out a full replacement, as shown in Photo No. 2.

Photo No. 2, everything you need to replace the pump

Designations in the photo:

- 1 - oil pump

- 2 – pan gasket

- 3 - pump gasket

- 4 - sealing ring

- 5 - sensor mounting bracket

Attention: The pumps of the VAZ 2108-1011010 and 2111, 2112-1011010 engines are almost the same, with the exception of point No. 5 - the sensor mounting bracket is different, do not miss this point!

Tip: It is recommended to install only a factory-produced gasket under the pump, since a non-standard gasket may have a thickness that does not meet the specifications and cause problems with the operation of the pump.

Necessary tool

- A set of wrenches (open-end - spanner preferably)

- Socket set and ratchet

- Two strong flathead screwdrivers

- Hexagon set

Emergency oil indication

Of course, now in almost all cars there is an emergency indication for a complete lack of pressure, this is known to us all - a “burning oil can”. If it does not go out for some time after starting, for example 10 - 20 seconds is one thing, it is almost always the fault of the oil filter. But if the lamp is constantly on, then this is already an alarm bell. Perhaps the oil pressure sensor has simply failed, or perhaps the oil pump has failed. In any case, the alarm indication is very important!

Remember this rule, if the lamp comes on, then turn off the car and preferably immediately to a service station, either a tow truck, or in tow.

Oil pressure in the VAZ 2112 16kl engine - logbook Lada 2110 GRAVICAPA 2001 on DRIVE2

I drove myself and didn’t know any grief, but a couple of days ago, I was driving in the evening, and as happens with Lada cars, when you let off the gas, the revolutions dropped to 500-700 and leveled off, but at the moment of the fall, I noticed that the emergency pressure lamp was blinking, maybe it was earlier It blinked like that, but I didn’t see it because I don’t drive much in the evening. Well, since I am a meticulous person regarding the condition of the car, I went looking. First of all, I measured the pressure on a cold and hot engine

When cold, my slightly decreasing (0.2-0.3) pressure gauge showed 2.5, when warmed up to 90 degrees it showed 0.3.

Thoughts were about the oil pump, liners, the ring on the oil receiver, the distributor bed and the distributors themselves. I started with the ring on the oil pump and the liners, removed the pan, then the oil receiver, everything turned out to be clean and without pieces of sealant, I unscrewed all the liners in turn, both the liners and the elbow did not raise any doubts, I only changed the ring on the receiver

I fill in new oil, and now we have 0.5-0.6 when hot. Well, it’s unlikely that the problem is in the ring, but rather in the new MANOL 1040 oil. I called naxi, he tried to dissuade me from buying a new oil pump, and recommended removing the valve cover and blowing into the hole of the emergency pressure sensor. I take off the cover, blow, and see oil splashing from under all the shaft journals. Well, now the thoughts are that the last person who assembled the cylinder head put everything on Kazan sealant, a crooked bed, etc... we take everything apart to get to the shafts and see this! The photo was taken immediately after removing the bed and removing the hydraulic seals, there is no sealant anywhere!

Now we wash everything we took out, and grind what we didn’t remove.

I washed and cleaned the bed, and went over it with 800-grit sandpaper to remove scratches and bring the bed at least a little closer to the shafts. We measure the shaft journals and see

If you look in the books, the new shafts are 23.9. Then I realized that it was better to change the shafts, naxi called again And here they lie

The shafts from the store drove 9 thousand, their measurement showed 23.87.

We apply LACTIDE, not Kazan and other sealants,

and screw up the bed

The tightening torque is 2 kg, but since everything was done with a small ratchet of 8, the torque wrench cannot be used (so we pull everything in a circle a little bit in about 3 passes, and with the last pass we tighten it without fanaticism. And then new seals, plugs and spark plug rings wells,

My rings were sealed, but I installed new ones without sealant. After assembly, the pressure on the hot one became

but some kind of hydraulic clunking in cylinders 2 or 3, the clattering is not strong but slightly noticeable, but noticeable damn it (well, I think I’ll drive for a while, maybe it will go away.

I think I’ve solved the pressure problem, the main thing is that the hydraulic fluid calms down now)

How to check oil pressure?

The actual check is carried out using a special device - a pressure gauge. It is also worth noting that you need to warm up the engine to operating temperature, usually 90 degrees Celsius. If you measure with a cold engine, especially in winter, the pressure can jump to high values, from 0.5 BAR or even higher, but measuring with a cold engine is WRONG!

In order to check the pressure, you need to find the emergency sensor, which is responsible for the indication on the dashboard. It is worth noting that it is not always located nearby and it is convenient to unscrew it. We unscrew it, and in its place we attach the test output connected to the pressure gauge.

The check can then be divided into two options:

- AT “idle” it is usually from 900 to 1200 rpm.

- Then at “higher” speeds, usually 4000 - 5000 engine speeds.

It is also worth noting that if you unscrew the emergency sensor, the “oil can” will light up on your instrument panel, this is normal. Now a short video showing how measurements are taken.

Engine oil pressure sensor and oil pressure light

Let's start with the fact that many experienced car enthusiasts know that the service life of the power unit directly depends on the quality of the oil and the normal operation of the lubrication system. Moreover, oil pressure is an important indicator of the condition of the internal combustion engine and even affects the overall safety during vehicle operation.

This is especially true in cases where it decreases, that is, the engine begins to experience oil starvation and may simply jam. If the engine jams while moving, this is considered an emergency situation that can lead to an accident and other unpredictable consequences. This fact is well known to the auto manufacturers themselves.

For this reason, you can find an oil pressure warning light on many cars. This light is located on the dashboard. This lamp lights up when the indicator falls below a certain level. Control is carried out using an oil pressure sensor. The ignition may also be accompanied by an audible signal.

It is important to understand that such a light may not light up even in cases of a significant decrease in the level of lubricant in the internal combustion engine, as well as when the pressure has decreased, but such a decrease is not yet critical.

For this reason, car owners often ask questions regarding what oil pressure in a diesel engine or gasoline unit (regardless of the make, model and type of vehicle) is normal. Many people are also interested in what the oil pressure should be on a cold engine.

Most often, this topic becomes relevant in cases where the oil pressure light blinks at idle while the engine is warming up. In other words, in all cases we are talking about the necessary diagnostics of the lubrication system. Let's figure it out.

What value should it be?

To begin with, it is worth noting that pressure is measured in bars (BAR), because we are measuring liquid. It’s unlikely that anyone will tell you the exact values now, because the structures of the engines are different, but there is a certain normal interval.

AT idle speed it is 2 BAR (or 0.2 MPa), for most cars

At 4000 - 5000 rpm - this is 4.5 - 6.5 BAR (0.45 - 0.65 MPa), also for most brands

If we take our VAZ 2112 16 valve version, then the pressure at idle is slightly higher, about 1.5 - 2.5 BAR. But at 4000 - 5000 rpm 0.4 - 0.6 BAR.

Actually, I’ll end here, I think the information was useful, read our AUTOBLOG.

Similar news

- Why do you close the radiator in winter? Let's say with cardboard, the necessary knowledge

- Mileage 100,000-150,000 km. Is it a lot or a little, what needs to be changed? Ra...

- OTTO cycle. ATKINSON. MILLER. What is it, what are the differences in...

Check and replacement

During operation of the VAZ-2112, various malfunctions may occur. For example, the oil pressure sensor may fail. However, before drawing conclusions about the causes or presence of a possible breakdown, you should first check the functionality of the device.

The check is performed as follows:

- First of all, check the circuit connecting the DDM and the control lamp. To do this, take the sensor wire and lean it against the surface of the engine. At the same time as this action, you should see if the light on the dashboard is on. If the lamp goes out, then the wiring is fine and the problem is really in the sensor.

- The next step is to remove the device from the vehicle for a visual inspection. The first sign of a breakdown is the presence of moisture on the sensor.

If the DDM turns out to be dry and everything is in order with the wiring, it is recommended to look for the problem elsewhere. For example, the malfunction may be in the oil level or its quality. You can also replace the oil filter if necessary.

There is another way to check the functionality of the sensor in the VAZ-2112. It is considered more reliable and proven. In this case, you will need to use a pressure gauge, and the sequence of actions will look like this:

- First of all, it is necessary to warm up the engine until it reaches operating temperature, and then turn it off.

- Next, you need to unscrew the sensor from the car and screw in the pressure gauge in its place.

- The ground wire of the pressure gauge will need to be connected to the ground of the vehicle.

- After this, you need to connect the control LED to the battery.

- The next action is to turn on the engine and press the gas pedal. In this case, it is necessary to take into account that the speed rises gradually.

When the action is completed, you should carefully monitor the pressure gauge and LED. If the device readings reach 1.2 and 1.6 bar, but the LED does not go out, then the sensor is faulty and needs to be replaced.

To carry out the replacement you will need:

- Stock up on the necessary tools, as well as a new sensor.

- Disconnect the wires from the old device.

Unscrew the sensor using a wrench.

Remove the unit

In this case, during the dismantling process, you should pay attention to the fact that the sealing ring should come out along with the sensor. It will also need to be replaced

- Install a new sensor.

- Check the contacts and clean them if necessary, then connect the wires.

When all the steps are completed, you can start the engine again and check the serviceability of the sensor.

What value should it be?

To begin with, it is worth noting that pressure is measured in bars (BAR), because we are measuring liquid. It’s unlikely that anyone will tell you the exact values now, because the structures of the engines are different, but there is a certain normal interval.

AT idle speed it is 2 BAR (or 0.2 MPa), for most cars

At 4000 - 5000 rpm - this is 4.5 - 6.5 BAR (0.45 - 0.65 MPa), also for most brands

If we take our VAZ 2112 16 valve version, then the pressure at idle is slightly higher, about 1.5 - 2.5 BAR. But at 4000 - 5000 rpm 0.4 - 0.6 BAR.

Actually, I’ll end here, I think the information was useful, read our AUTOBLOG.

(4 votes, average: 2.75 out of 5)

Similar news

Why do you close the radiator in winter? Let's say with cardboard, the necessary knowledge

Mileage 100,000-150,000 km. Is it a lot or a little, what needs to be changed? Ra.

OTTO cycle. ATKINSON. MILLER. What is it, what are the differences in ra.

Comments

Good day everyone, I decided to write my review of the 2010 Toyota Avensis. Just want…

TOP articles for the month

I have many different articles and videos on various gearboxes, for example here...

I already have an article on the website about choosing memory cards (you can see it here), it’s very...

In the article - is it possible to open windows when the air conditioner is running (you can read it here), I was asked...